Material for regulating humidity and preparation method and application thereof

A technology of humidity and compression molding, which is applied in the field of humidity-controlling materials and its preparation, can solve the problems of not being able to adjust the humidity of the environment and not being invariable, and achieve intelligent adjustment of the humidity of the living environment, enhanced mechanical properties, and enhanced heat and mass transfer performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

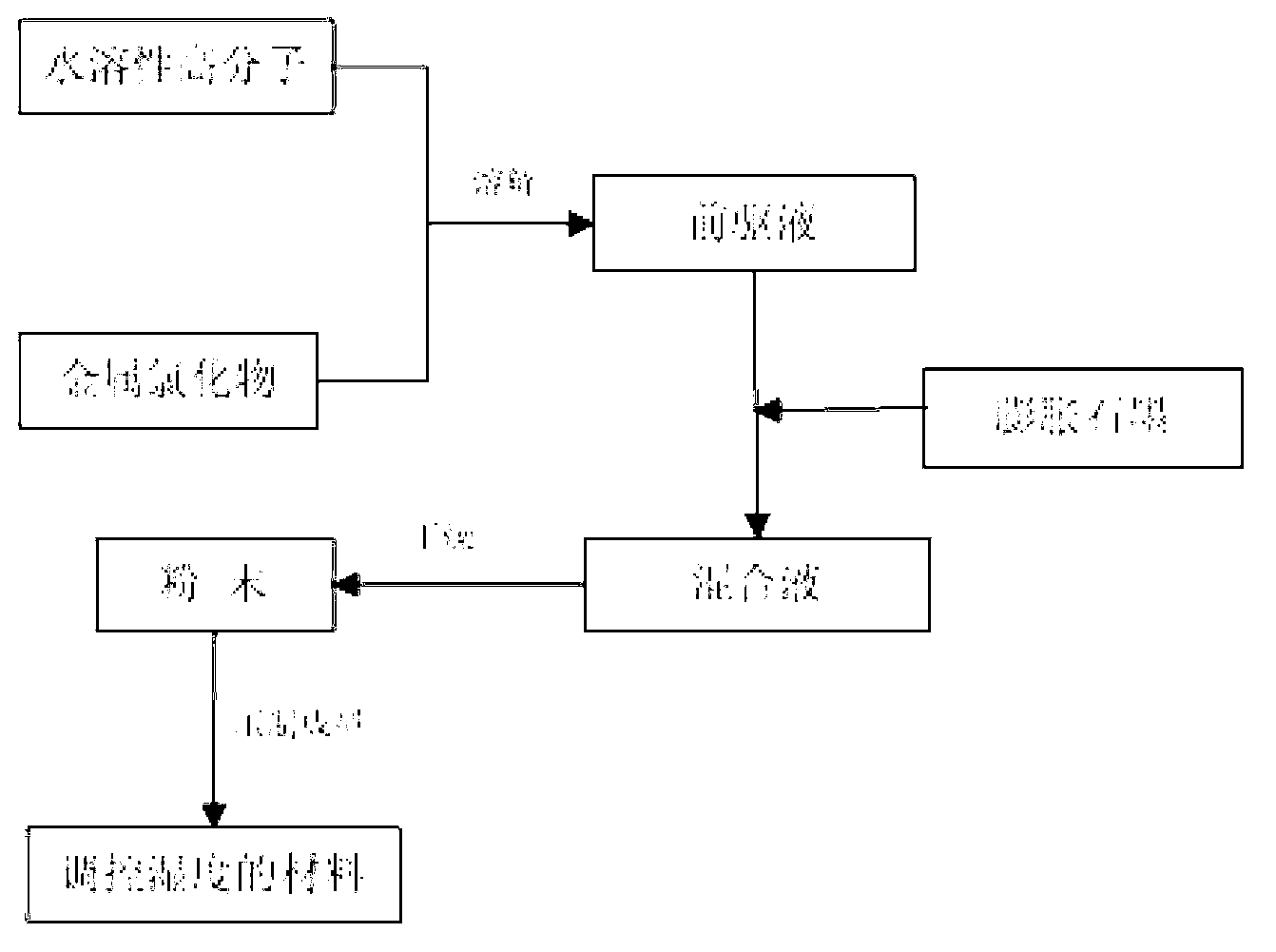

[0028] Correspondingly, the present invention also provides a method for preparing the above-mentioned humidity-regulating material, comprising the following steps:

[0029] The first step: the metal chloride and the water-soluble polymer compound are mixed to obtain a precursor solution. The method for dissolving the metal chloride and the water-soluble polymer compound is not particularly limited in the present invention, methods well known to those skilled in the art can be adopted, such as dissolving the metal chloride first, and then adding the water-soluble polymer compound, or at the same time The metal chloride and the water-soluble polymer compound are added to the water to dissolve together, and in order to make the dissolution more rapid, it can also be stirred or heated during the dissolution.

[0030] The second step: adding expanded graphite to the precursor solution obtained in the first step to obtain a mixed solution. Those skilled in the art will easily know...

Embodiment 1

[0035] Take 1000ml of water, dissolve 8.00g of calcium chloride in it, weigh 4.00g of polyethylene oxide and slowly dissolve in the calcium chloride solution after the calcium chloride is completely dissolved, and dissolve the polyethylene oxide completely to obtain the precursor solution; Insulate at 500° C. for 10 minutes to prepare expanded graphite; then weigh 4.00 g of expanded graphite and put it into the precursor solution, and stir for 1 minute until the expanded graphite is evenly dispersed to obtain a mixed solution. Put the mixed solution in a drying oven at 95° C. for 2 to 3 days until the mixed solution is completely dried to obtain the mixed solution powder. Weigh 4.00g of the powder and place it in a mold and press it under a pressure of 20MPa for 5min to obtain a block-shaped humidity-regulating material.

[0036] Put the block-shaped humidity-controlling material obtained in Example 1 into an indoor environment, the material will automatically adsorb at high h...

Embodiment 2

[0038] Take 2500ml of water, dissolve 7.50g manganese chloride in it, after the manganese chloride is completely dissolved, take 15.00g polyacrylic acid and slowly dissolve it in the manganese chloride solution, and the polyacrylic acid is completely dissolved to obtain the precursor solution; Insulate at ℃ for 8 minutes to prepare expanded graphite; then weigh 15.00 g of expanded graphite and put it into the precursor solution, and stir for 1 minute until the expanded graphite in the solution is uniformly dispersed to obtain a mixed solution. Put the mixed solution in a drying oven at 90° C. for 2 to 3 days until the mixed solution is completely dried to obtain the mixed solution powder. Weigh 3.50g of the powder and place it in a mold and press it under a pressure of 14MPa for 5min to obtain a block-shaped humidity-controlling material.

[0039] Put the block-shaped humidity-controlling material obtained in Example 2 into an indoor environment, the material will automaticall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com