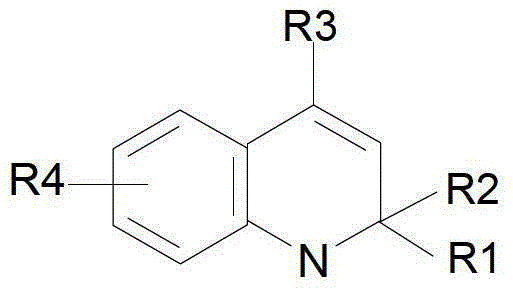

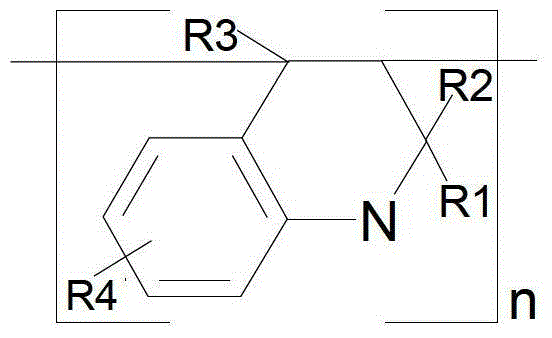

Worm gear oil composition and preparation method thereof

An oil composition, worm gear technology, applied in the directions of lubricating composition, petroleum industry, additives, etc., can solve the problems of affecting the demulsification of oil products, polluting and blocking equipment, insufficient oxidation resistance, etc., and achieve excellent antioxidant synergy, The effect of preventing copper corrosion and high oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] The preparation method of the worm gear oil composition provided by the present invention includes: adding one or more polyether oil base oils into a container with stirring, and then adding the above-mentioned B component, C component, D component, E Component, F component, G component and optional H component are stirred at 20-60°C until uniform and transparent.

[0055] The present invention simulates the thermal oxidation stability test of the CRC L-60 gear bench in the laboratory by the oven oxidation experiment. No. steel test piece (45mm×25mm×2mm), then put the beaker in an oven, oxidize at a constant temperature of 150°C for 192h, then take out the steel piece, rinse with petroleum ether, observe the discoloration of the steel piece and the sediment at the bottom of the cup. Grade 0 is unchanged; Grade 1 is slightly discolored; Grade 2 is partially pale white; Grade 3 is mostly pale white; Grade 4 is gray, blue, yellow, or off-white; Grade 5 is partially gray-bl...

Embodiment 1

[0059] Add 100 parts of water-insoluble polyether base oil Emkarox VG222 (Croda Company, Inc, the same below) into a stainless steel mixing kettle with agitator, keep the temperature of the kettle at 40°C, and then add 0.6 parts of Naugalube TMQ (2,2 , 4-trimethyl-1,2-dihydroquinoline antioxidant, Uniroyal Chemical Company, Inc. the same below), 0.08 parts of benzotriazole derivatives T551 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., below same), 1 part of tricresyl phosphate T306 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 1 part of diisobutyl dithiophosphate, 0.6 part of ethylene glycol oleate, 0.002 part of methyl silicone oil T901 (Jinzhou Kangtai Lubricating Oil Additive Co., Ltd., the same below), 0.003 parts of demulsifier ethylene oxide / propylene oxide block copolymer 5957 (Lubrizol Petroleum Chemical Company, the same below) was added into the blending kettle, started stirring until the mixture was completely dissolved, uniform and t...

Embodiment 2

[0067] Add 100 parts of water-insoluble polyether base oil Emkarox VG462 (Croda Chemical Company, Inc) into a stainless steel blending kettle with agitator, keep the temperature of the kettle at 50°C, and then add 1.8 parts of Naugalube TMQ, 0.04 parts of benzene three Azole derivatives T551, 1 part tricresyl phosphate T306, 1 part diisobutyl phosphorodithioate, 0.1 part benzotriazole octadecylamine salt, 0.003 part T901, 0.005 part Add 5957 into the blending kettle, start stirring until the mixture is completely dissolved, uniform and transparent, and the worm gear oil composition E is obtained.

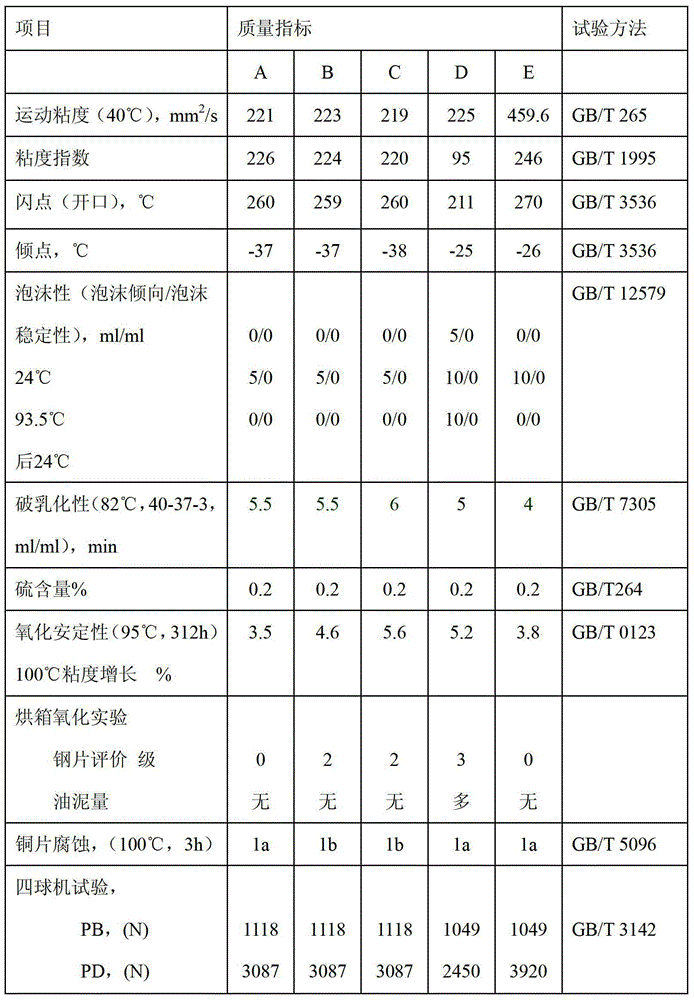

[0068] The worm gear oil compositions A, B, C, D and E obtained by the method are shown in Table 1 after test results verification.

[0069] Table 1

[0070]

[0071]The results in Table 1 show that, compared with mineral oil-based worm gear oils, polyether-based oils exhibit better extreme-pressure and anti-wear properties, oxidation resistance, viscosity-temperature In addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com