System for generating sewage gas by straw

A straw and biogas technology, applied in the field of biogas, can solve the problems of many controlled factors and low biogas yield, and achieve the effects of ensuring biogas output, high crushing efficiency, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

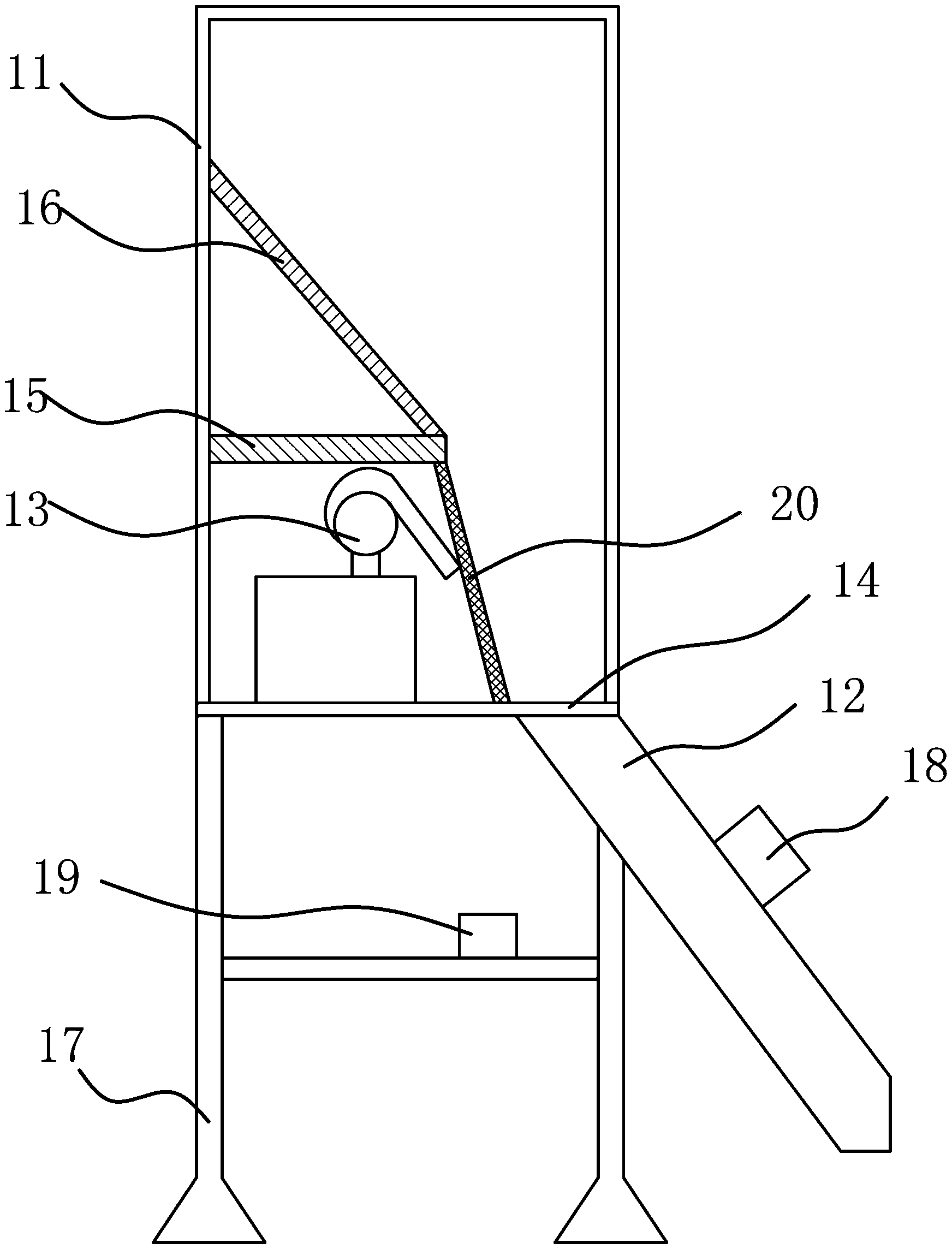

[0032] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

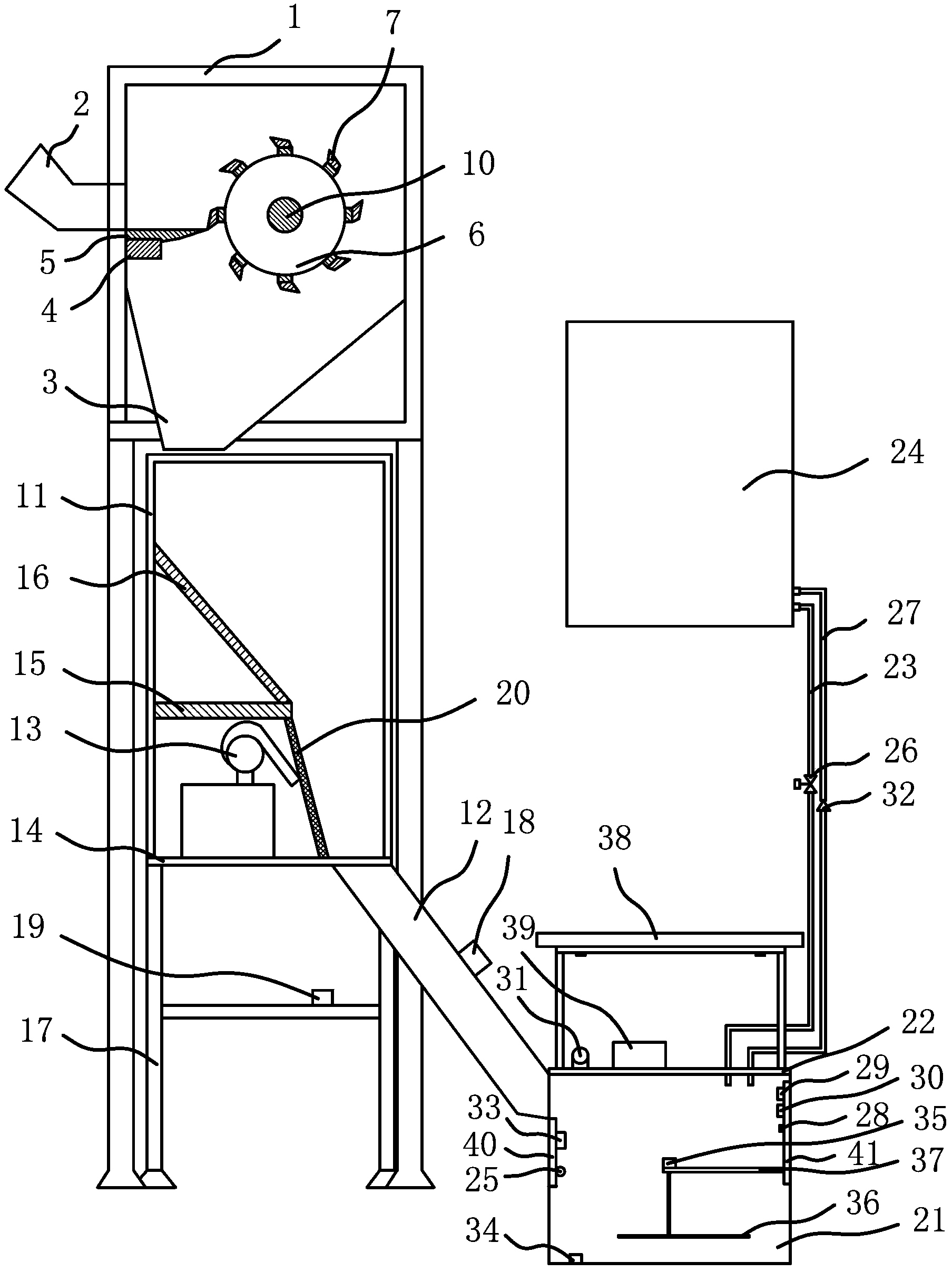

[0033] Such as figure 1 As shown, a system for generating biogas from straw includes a straw crusher, a conveying device and a biogas digester, and the conveying device is arranged between the straw crusher and the biogas digester.

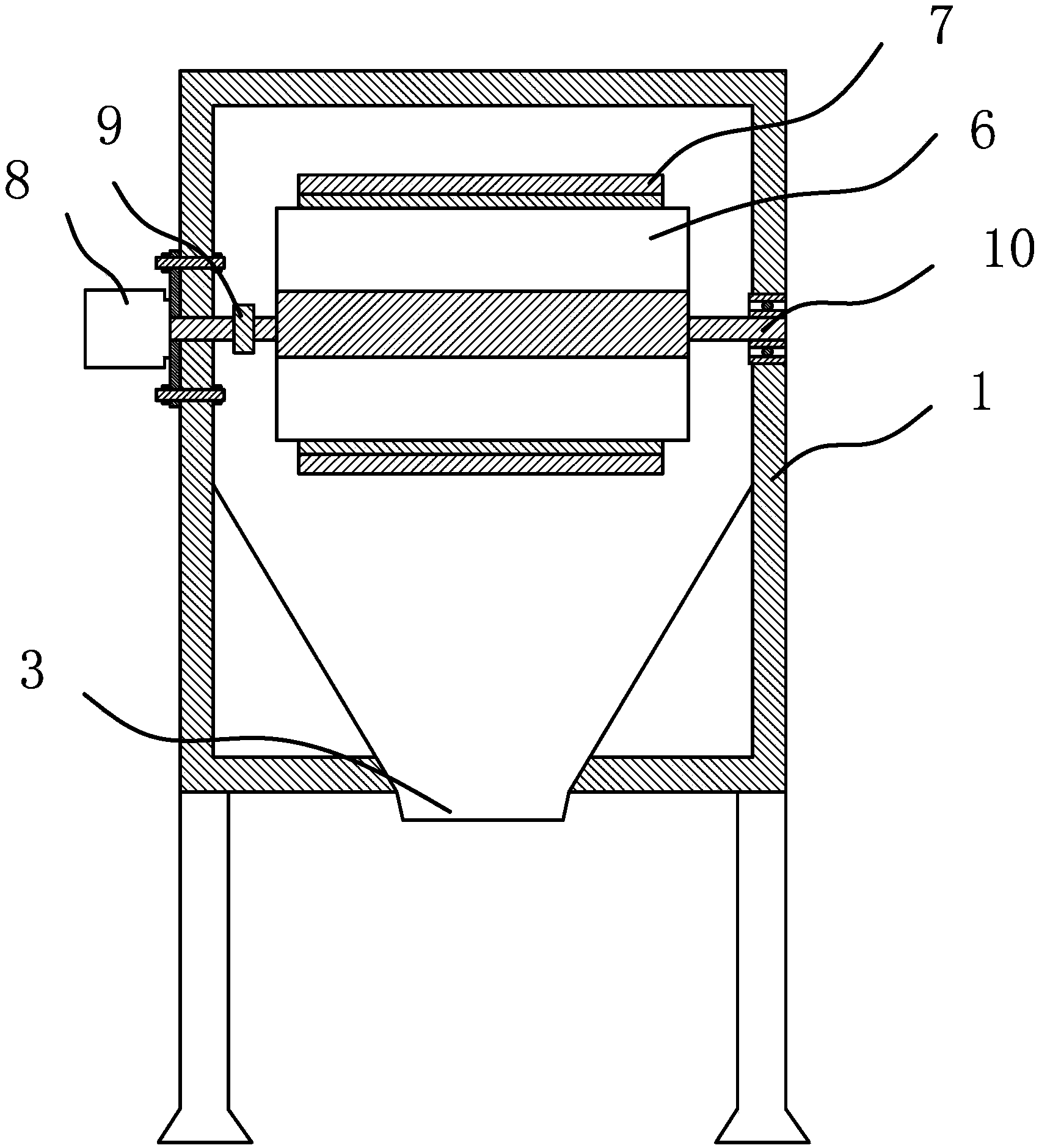

[0034] Such as figure 2 As shown, the straw crusher includes a barrel 1 with a cavity inside. The side of the barrel 1 is provided with a feed port 2 communicating with the inner cavity, and the lower part of the barrel 1 is provided with a barrel that communicates with the inner cavity. Outlet 3. A fixed knife rest 4 is fixed on the inner wall of the machine barrel 1 by screws, and a fixed blade 5 is fixed on the fixed knife rest 4 by screws, and the fixed knife rest 4 and the fixed blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com