Stator permanent magnetic flux-switching bearing-free motor with U-shaped teeth

A bearingless motor, flux switching technology, applied in the direction of magnetic circuit shape/style/structure, winding conductor shape/style/structure, electrical components, etc., can solve the problems of heat dissipation and mechanical firmness, efficiency, power The factor is not as good as that of permanent magnet motors, and the utilization rate of permanent magnets is reduced, achieving the effects of compact structure, low loss, and high power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

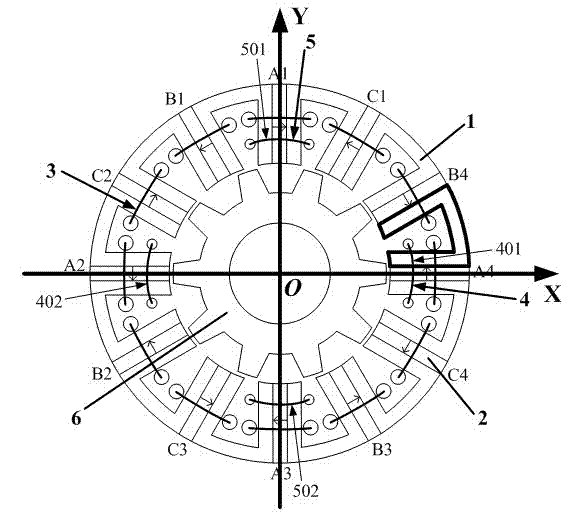

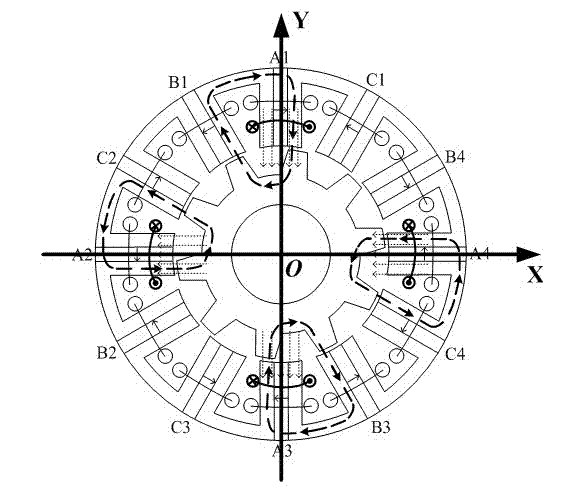

[0028] Taking a three-phase stator 12-pole / rotor 10-pole stator permanent magnet flux switching bearingless motor as an example, its cross-sectional view is as follows figure 1 The schematic diagram of the structure of the stator permanent magnet flux switching bearingless motor shown includes the stator 1 and the rotor 6, the rotor 6 is located inside or outside the stator 1, both the stator 1 and the rotor 6 are salient pole structures, and the stator 1 is provided with three Relatively symmetrical centralized armature winding 3 , X-axis suspension winding 4 , Y-axis suspension winding 5 and permanent magnet 2 . There are 12 evenly distributed poles on the stator 1, and 10 evenly distributed poles on the rotor 6; the stator core is composed of 12 "U"-shaped conductive core units (such as figure 1 As shown in the part drawn by the middle thick black line, since the flux switching motor itself is a new type of motor, its stator structure is usually composed of a "U"-shaped per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com