Method to remove residual pesticide procymidone from ginseng extract

A technology for extracting ginseng and residual pesticides, which is applied in pharmaceutical formulas, plant raw materials, medical preparations containing active ingredients, etc., can solve the problems of high operating pressure, high pesticide residues, and large equipment investment, and achieve high recovery rate and low cost. Low, good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Weigh 50g ginseng extract sample (purchased from Ningbo Jinai Nong Biotechnology Co., Ltd.), dissolve it in 45°C water with 3 times the volume (v / m), let it stand for 0.5-1 hour, let it cool, add mixed solvent A for extraction , the amount of mixed solvent for each extraction is 1 / 3~1 of the solution volume, a total of 5 extractions, and each extraction is left to stand for 60 minutes. After the extraction is completed, the lower aqueous solution is concentrated to a specific gravity of 1.2 (measured by a Bomer meter), and placed at 70 ° C. Dry in a vacuum oven for 4 hours, pulverize, and pass through a 120-mesh sieve to obtain the finished product.

[0022] The mixed solvent A is a mixed solvent of n-hexane, ethyl acetate and acetone, and its mixing volume ratio is n-hexane:ethyl acetate:acetone=8:2:0.5 (v / v / v).

Embodiment 2

[0024] Take 50g of ginseng extract sample, dissolve it in warm water at 40°C with 6 times the volume (v / m), let it stand for 0.5-1 hour, let it cool down, add mixed solvent A for extraction, the amount of mixed solvent added for each extraction is 1 / 2 of the volume of the solution 1 / 3 to 1, a total of 5 extractions, and each extraction was left standing for 50 minutes. After the extraction was completed, the lower aqueous solution was concentrated to a specific gravity of 1.2 (measured by a Bommer meter), dried in a vacuum oven at 70°C for 4 hours, crushed, and passed through 120 Mesh sieve to get the finished product.

[0025] The mixed solvent A is a mixed solvent of n-hexane, ethyl acetate and acetone, and its mixing volume ratio is n-hexane:ethyl acetate:acetone=6:4:1 (v / v / v).

Embodiment 3

[0027] Take 50g of ginseng extract sample, dissolve it in 80℃ warm water with 7 times the volume (v / m), let it stand for 0.5-1 hour, let it cool down, add mixed solvent A for extraction, the amount of mixed solvent added for each extraction is 1 / 2 of the solution volume 1 / 3~1, a total of 5 extractions, and each extraction was left standing for 30 minutes. After the extraction was completed, the lower aqueous solution was concentrated to a specific gravity of 1.2 (measured by a Bommer meter), dried in a vacuum oven at 70°C for 4 hours, crushed, and passed through 120 Mesh sieve to get the finished product.

[0028] The mixed solvent A is a mixed solvent of n-hexane, ethyl acetate and acetone, and its mixing volume ratio is n-hexane:ethyl acetate:acetone=7:3:0.5 (v / v / v).

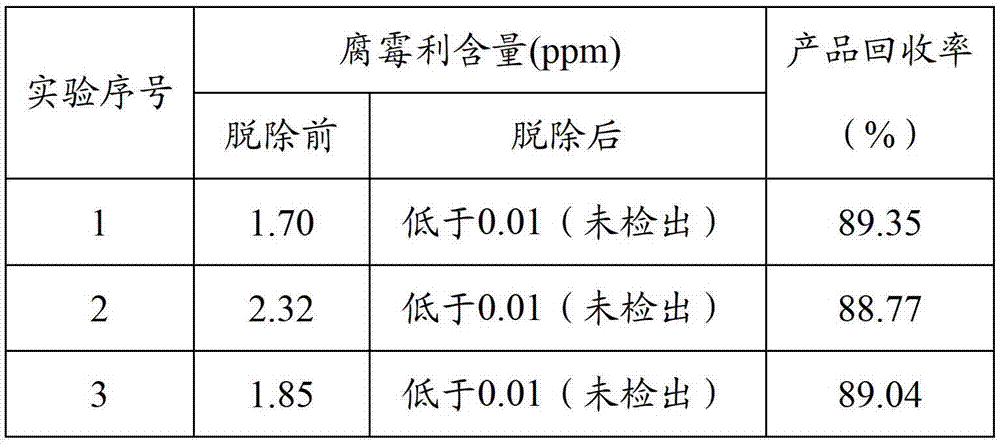

[0029] Determination of the content of procymidone in the ginseng extract before and after removal in Example 1-3. Calculate removal rate and product recovery. (Product recovery rate = sample weight of ginse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com