Graphite powder-butyl rubber composite frozen gel oil absorption material and preparation method thereof

A kind of technology of butyl rubber and oil absorbing material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

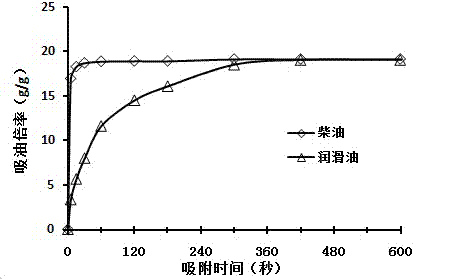

Image

Examples

Embodiment 1

[0024] (1) Shred butyl rubber, weigh 5g (5%, w / v) and dissolve it in 100mL benzene, add a stir bar, react overnight under magnetic stirring, and disperse the benzene solution of rubber evenly.

[0025] (2) Weigh 0.025 g (0.5%, w / w) of graphite powder, ultrasonically disperse it with 10 mL of benzene, pour it into the above reaction solution, and stir evenly. Then add the crosslinker S dropwise under stirring 2 Cl 2 3.0mL (6%, v / w), the mixture was dispensed into stoppered test tubes, covered and reacted at -5°C for 24 hours in a low-temperature constant temperature reaction tank.

[0026] (3) After the reaction is complete, take out the test tube and melt at room temperature for 30 minutes. Squeeze out the solvent benzene in the material, and wash alternately with toluene and methanol, at least twice each.

[0027] (4) Dry in a fume hood at room temperature to obtain the oil-absorbing material.

[0028] The obtained fully dried oil-absorbing material is immersed in water,...

Embodiment 2

[0033] (1) Shred butyl rubber, weigh 5g (5%, w / v) and dissolve it in 100mL benzene, add a stirrer, react overnight under magnetic stirring, and disperse the benzene solution of rubber evenly.

[0034] (2) Weigh 0.05g (1%, w / w) graphite powder, ultrasonically disperse it with 10mL benzene, pour it into the above reaction solution, and stir evenly. Then add the crosslinker S dropwise under stirring 2 Cl 2 3.0mL (6%, v / w), the mixture was divided into stoppered test tubes, covered and reacted at -2°C for 24 hours in a low-temperature constant temperature reaction tank.

[0035] (3) After the reaction is complete, take out the test tube and melt at room temperature for 30 minutes. Squeeze out the solvent benzene in the material, and wash alternately with toluene and methanol, at least twice each.

[0036] (4) Dry in a fume hood at room temperature to obtain the oil-absorbing material.

[0037] The obtained fully dried oil-absorbing material was immersed in water and methanol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com