Process method and apparatus for directly producing mineral wool from thermal state blast furnace slag

A technology of blast furnace slag and process method, which is applied in the direction of manufacturing tools and glass manufacturing equipment, etc. It can solve the problems of increased energy consumption required for slag supplementary heating, complicated operation, and difficulty in receiving large slag bags, so as to reduce heat loss , stable chemical composition, and the effect of improving its own value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

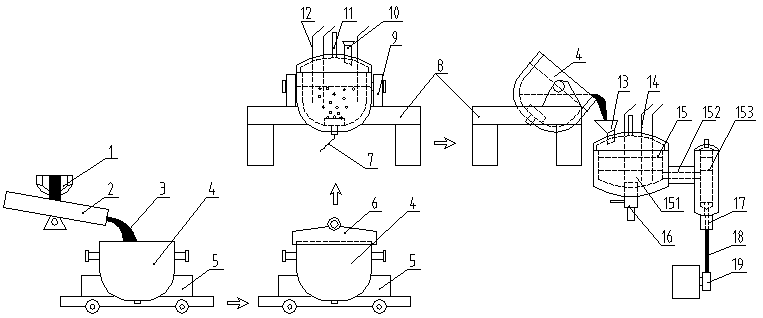

[0025] Such as figure 1 As shown, a device for directly producing mineral wool from hot blast furnace slag includes a slag feeding chute 2, a slag bag 4, a slag bag car 5, a slag bag cover 6, a tilting mechanism 8, a lifting mechanism 9, a homogenizing furnace 15 and Centrifugal cotton machine 19, the slag bag 4 is set on the slag bag car 5, the bottom of the slag bag 4 is provided with a stirring gas inlet 7, and the slag bag cover 6 is provided with a feeding port 10, an exhaust port 11 and a heating electrode 12. The slag charter car 5 has a slag removal station and a tempering station. When the slag charter car 5 is at the slag removal station, the slag bag 4 is connected to the blast furnace slag ditch 1 through the slag feeding chute 2, and the slag charter car 5 is at the tempering station. When the slag bag 4 cooperates with the tipping mechanism 8 through the lifting mechanism 9; the homogeneous furnace 15 is provided with a feed port 13, and the tipping mechanism 8 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com