High-performance adhesive and application thereof in electrode preparation

A binder and high-performance technology, applied in the direction of non-polymer binder additives, adhesives, battery electrodes, etc., can solve the problems that cannot be improved well, and achieve good cycle performance and long cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

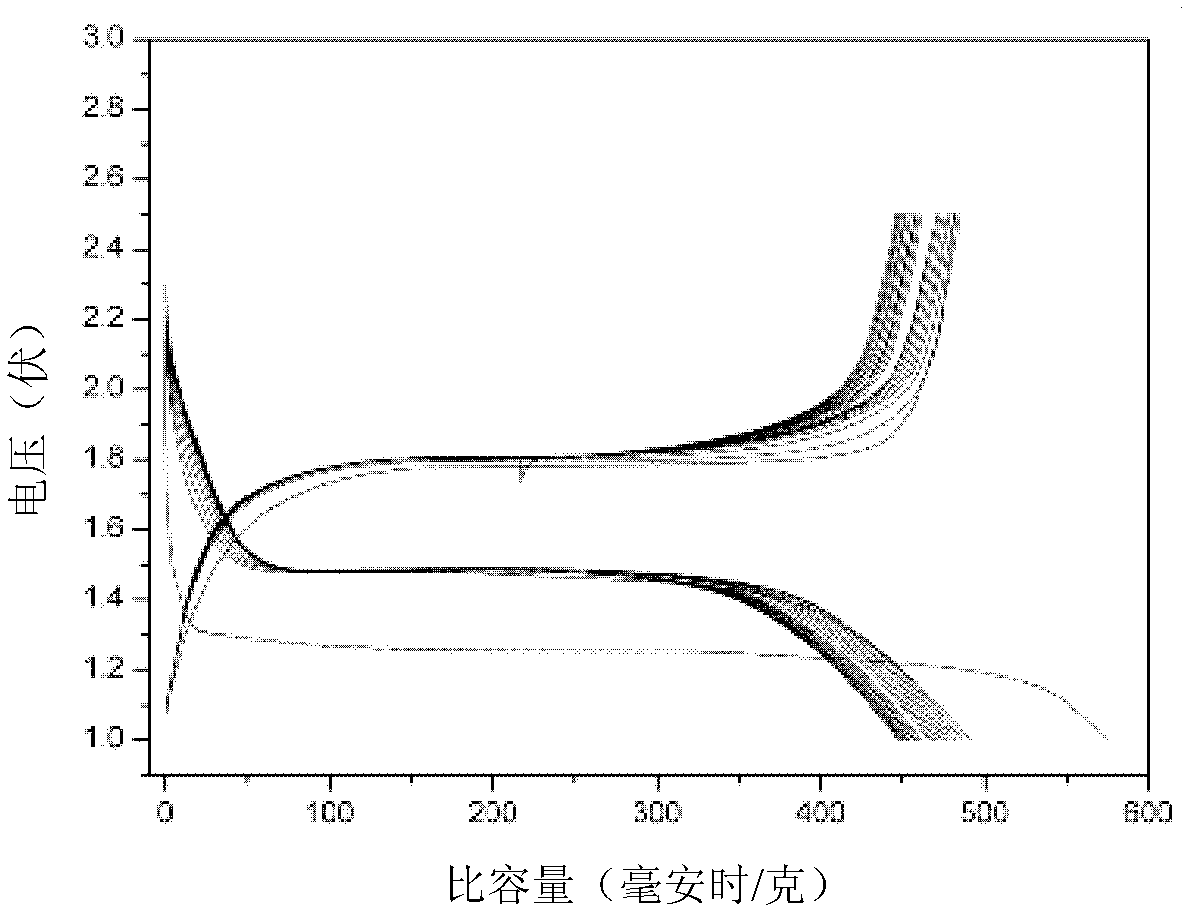

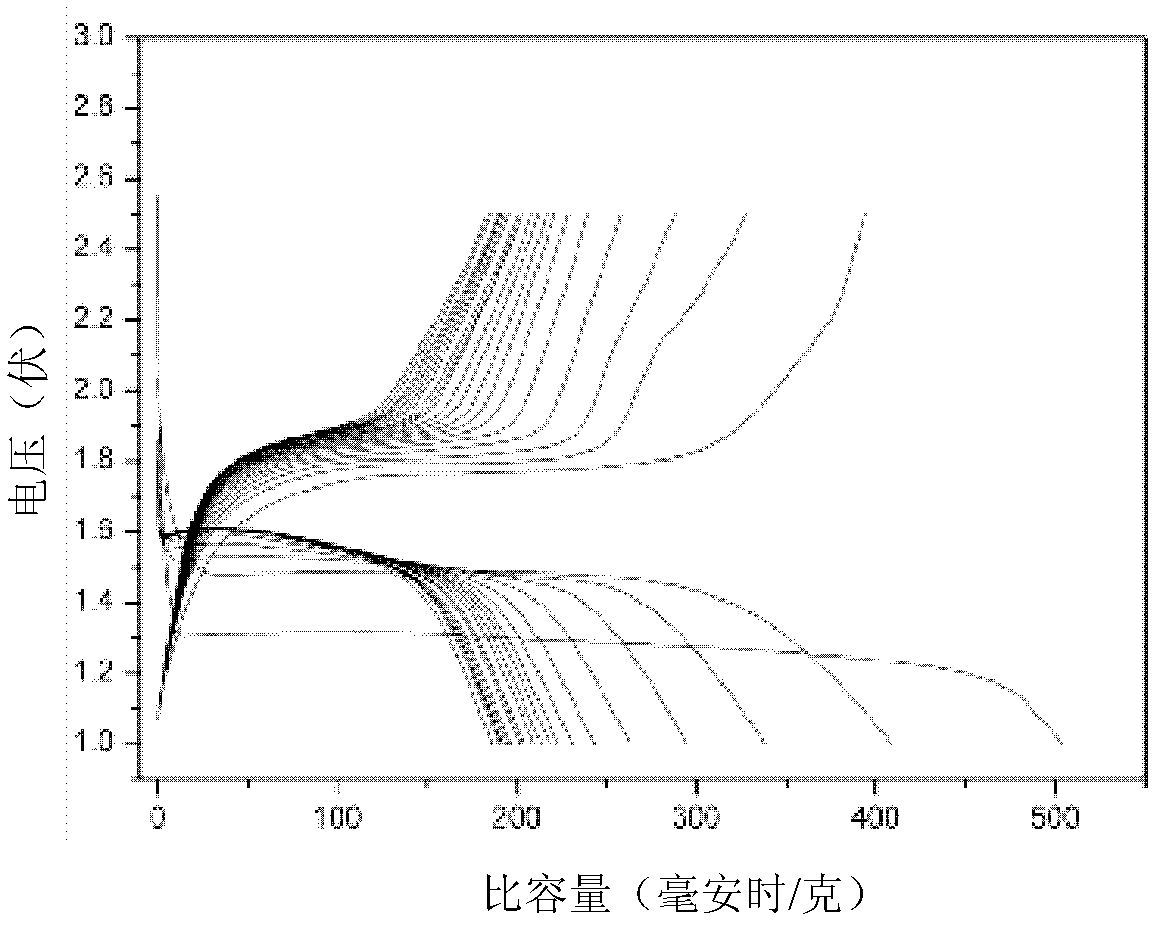

[0026] This example is used to illustrate the preparation of the binder of the present invention and its use in the production of FeS electrodes, as well as its application in lithium-ion batteries.

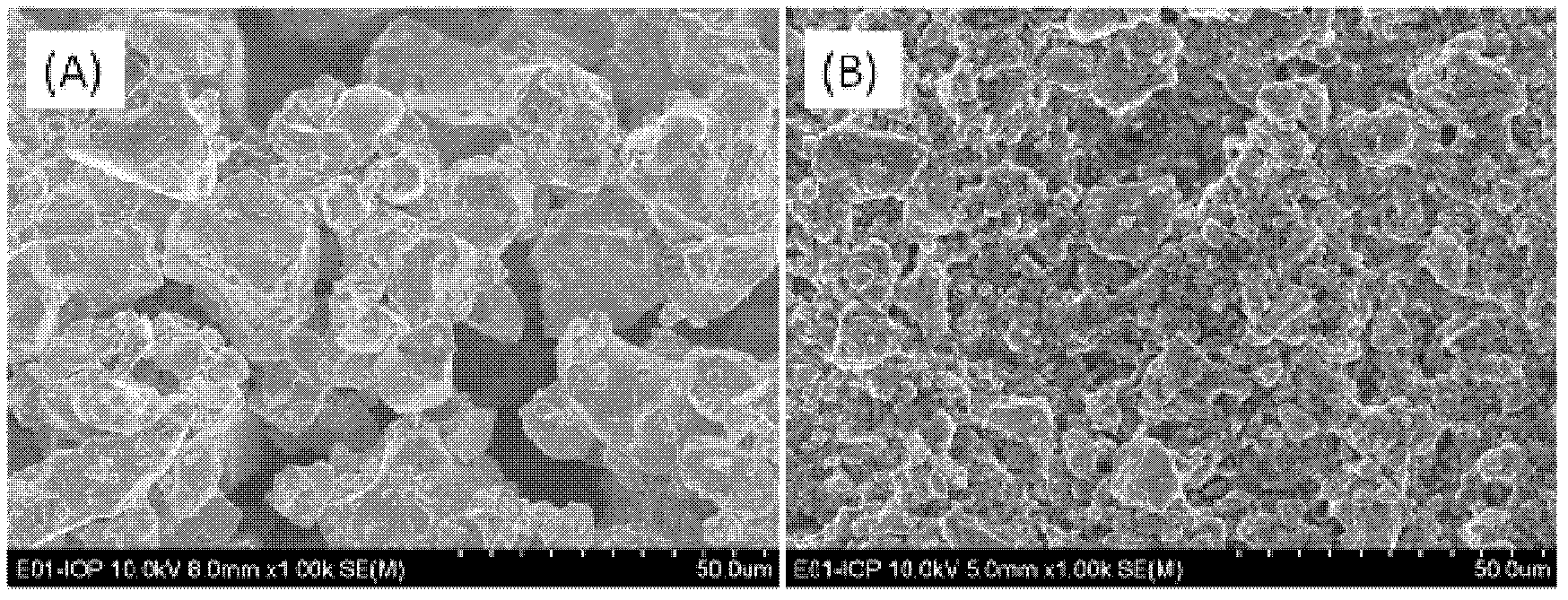

[0027] Weigh NaAlg and CMC according to the mass ratio of 5:5, grind and mix well before use. The preparation process of the FeS electrode is as follows: Weigh the FeS powder, the conductive additive acetylene black, and the binder NaAlg and CMC mixed powder of the present invention in a ratio of 8:1:1. After grinding and mixing FeS powder and acetylene black, add binder powder to grind and mix evenly, then add an appropriate amount of distilled water, and grind until a uniform black paste is formed. Then the slurry is evenly coated on the copper foil, and the slurry is dried to form a uniform film, which is well bonded to the copper foil. The dried pole pieces were cut into 8×8mm pole pieces, dried under vacuum conditions at 100oC for 10 hours, and then transferred into a glove...

Embodiment 2

[0029] This example is used to illustrate the preparation of the binder of the present invention and its use in the production of FeS electrodes, as well as its application in lithium-ion batteries.

[0030] Weigh NaAlg and CMC according to the mass ratio of 6:4, grind and mix well before use. FeS electrode preparation, battery assembly and testing process are the same as in Example 1. The discharge capacity of the battery in the first week was 570mAh / g, the efficiency in the first week was 82.3%, and the capacity retention rate after 20 weeks was 93.7%.

Embodiment 3

[0032] This example is used to illustrate the preparation of the binder of the present invention and its use in the production of FeS electrodes, as well as its application in lithium-ion batteries.

[0033] Weigh NaAlg and CMC according to the mass ratio of 8:2, grind and mix well before use. FeS electrode preparation, battery assembly and testing process are the same as in Example 1. The discharge capacity of the battery in the first week was 560mAh / g, the efficiency in the first week was 80.5%, and the capacity retention rate after 20 weeks was 94.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com