Skin-touch polyurethane leather surface treating agent and preparation method thereof

A technology of polyurethane leather and surface treatment agent, used in fiber treatment, textiles and papermaking, etc., to achieve the effect of improving wear resistance, enhancing touch, skin feel and strong feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

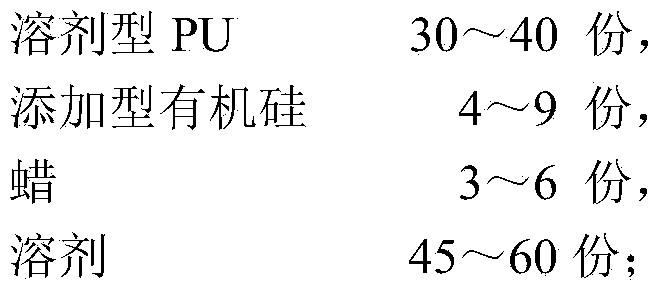

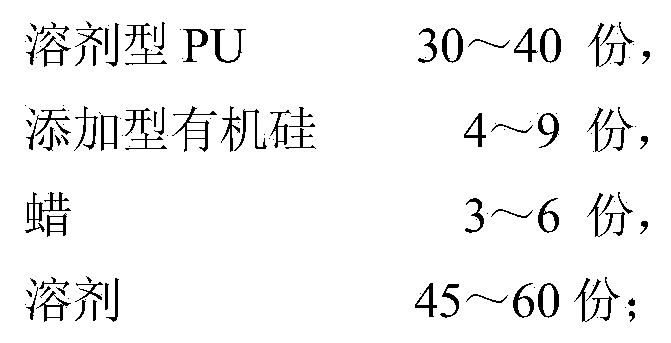

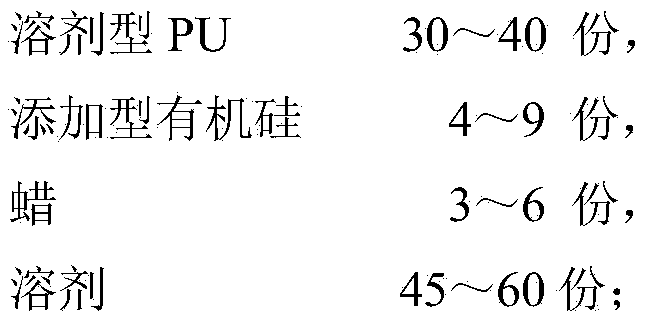

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of this skin feeling polyurethane leather surface treatment agent is as follows:

[0029] (1) Weigh the wax, silicone and solvent according to the proportion, add them into the reactor, and stir at room temperature for 20-40min;

[0030] (2) Add 40% of the total amount of solvent-based PU resin, and stir at room temperature for 50 to 70 minutes;

[0031] (3) Add the remaining solvent-based PU resin and stir at room temperature for 50-70 minutes;

[0032] (4) filter with 120 order polypropylene nets, obtain finished product;

[0033] Described solvent type PU resin synthesis technique is:

[0034] (a) Add polyols, antioxidants and some solvents into the reaction kettle, heat up to 50°C, and stir for 20-40 minutes;

[0035] (b) Add 70% of the total amount of diisocyanate according to the proportion, and react at 70-80° C. for 1.5-3 hours;

[0036] (c) adding chain extender and reactive silicone, reacting at 70-80°C for 1-1.5 hours;

[0037] (d)...

Embodiment 1

[0041] (1) Preparation of solvent-based PU: Add polyol 150g (wherein by weight polytetrahydrofuran diol 50%, polyadipate-1,4-butylene glycol ester diol 25%, polyol 25% in a 1L reactor) Caprolactone diol 25%,), solvent (dimethylformamide) 225g, antioxidant (antioxidant 1010) 0.5g, be warming up to 50 ℃, stir 30min; Add diisocyanate 49g (accounting for 70% of total addition %) (wherein by weight isophorone diisocyanate 30%, hydrogenated diphenylmethane diisocyanate 70%), react at 70-80°C for 1h; add chain extender (1.4-butanediol) 16g and organic silicon ( Dihydroxy silicone) 10g, add 0.1g of catalyst stannous octoate, react at 70-80°C for 2h; cool down to 65°C, gradually add 21g of diisocyanate (diphenylmethane diisocyanate) (accounting for 30% of the total amount), to the resin Viscosity reaches 120,000 cps / 25 ℃, then adds solvent 350.2g (wherein by weight dimethylformamide 30%, butanone 70%), finally obtains polyurethane resin 821.3g, solid content 30%, viscosity 70,000 cps / ...

Embodiment 2

[0044](1) Preparation of solvent-based PU: Add polyol 150g (wherein by weight polyethylene adipate glycol 50%, polyoxypropylene glycol 30%, polyethylene adipate Diol-1,4-butanediol ester diol 20%, ), solvent (dimethylformamide) 225g, antioxidant (antioxidant 1010) 0.5g, heat up to 50°C, stir for 30min; add diisocyanate 56g (Diphenylmethane diisocyanate), react at 70-80°C for 2h; add 21.5g of chain extender (30% by weight of ethylene glycol, 30% of 1,6-hexanediol, 40% of neopentyl glycol) React with 7.5g of silicone (diamino silicone) at 70-80°C for 2h; add 0.1g of catalyst stannous octoate and react at 75°C for 1h; at 65°C, gradually add 24g of diisocyanate (diphenylmethane diisocyanate) to The viscosity of the resin reaches 118,000 cps / 25°C, and then 369.3 g of (dimethylformamide) is added. Finally, 863.4 g of polyurethane resin was obtained, with a solid content of 30% and a viscosity of 67,000 cps / 25°C.

[0045] (2) Preparation of surface treatment agent: Add 6g of wax (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com