Method and device for cooling and waste heat recovery of flash smelting furnace body

A flash smelting furnace and waste heat recovery technology, applied in furnace cooling, steam generating devices, furnaces, etc., can solve the problem that the cooling water jacket cannot meet the cooling requirements of the production load, and save cooling water, reduce volume, and reduce power energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

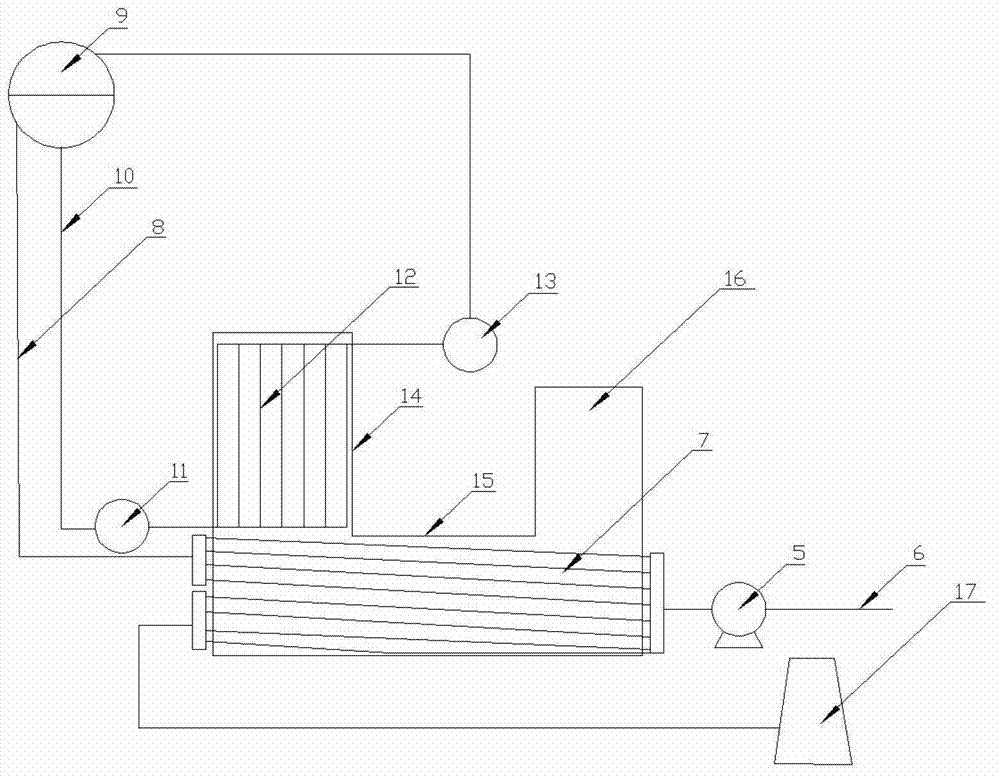

[0026] The flash smelting furnace cooling waste heat recovery method provided by the present invention is to cool the flash furnace in partitions, the sedimentation tank is cooled by forced circulation, the reaction tower is vaporized by membrane-type natural circulation water cooling, and the wall temperature of the water-cooled wall of the reaction tower is kept below 280 ℃, to generate low-pressure steam with a pressure of <1.5Mpa, to recover the waste heat from cooling the flash smelting furnace, and to meet the cooling demand of the reaction tower load change.

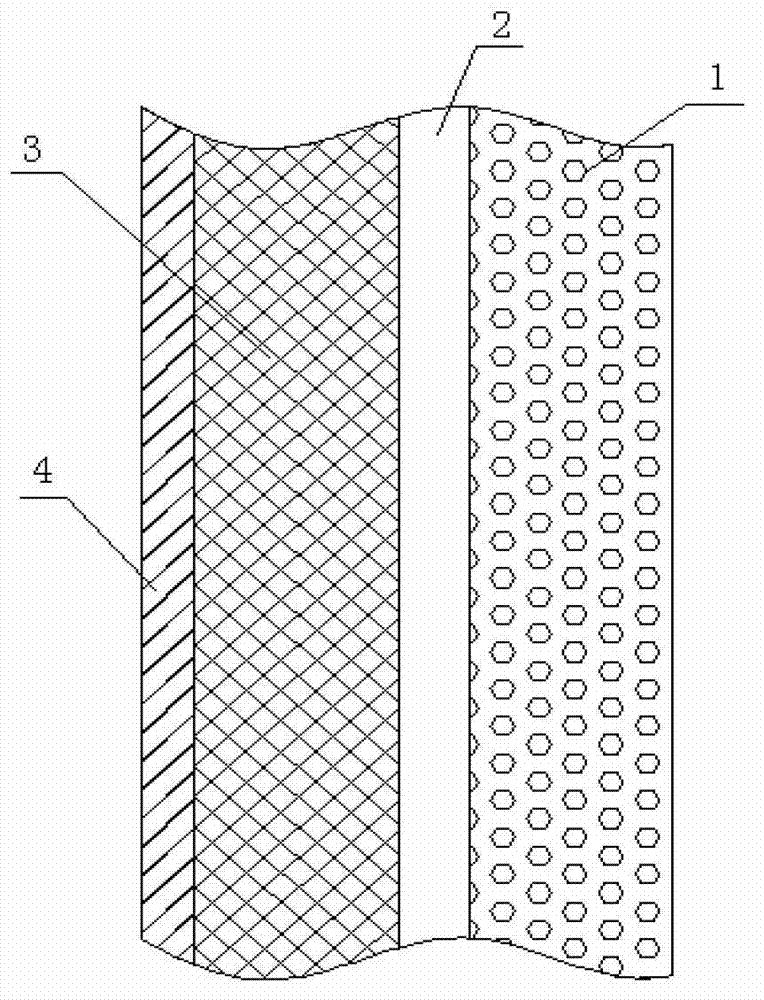

[0027] see figure 1 and figure 2 , the device provided by the present invention realizes the method for recovering waste heat from flash smelting furnace cooling. One end of the sedimentation tank 15 is connected to the reaction tower 14, and the other end is connected to the ascending fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com