Method for testing ammonia escape of flue gas denitrification system

A technology of ammonia escape and detection method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as uneven distribution of ammonia escape, difficult splicing of heating guns, and sampling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] NH to be purchased 4 + The standard solution was diluted and prepared to obtain standard solutions with a mass concentration of 0.2mg / L, 1.0mg / L, 2.0mg / L, 4.0mg / L and 10.0mg / L, and the above series of concentrations of NH 4 + The standard solution was detected by ion chromatography, the inhibition current detected by ion chromatography was 59mA, the quantitative loop volume was 10μL, the separation column was CS12A-4×250mm cation separation column, the elution method was isocratic elution, and the flow rate of the eluent was 1.0mL / min, the column temperature is 30°C, the cell temperature is 35°C, and the column pressure is 1200psi;

[0086] The standard solution of each concentration was detected in parallel 3 times to obtain the corresponding peak areas of the standard solutions of each concentration, and then the concentration-peak area curve was fitted by the least squares method for calibration to obtain the NH 4 + standard curve.

Embodiment 2

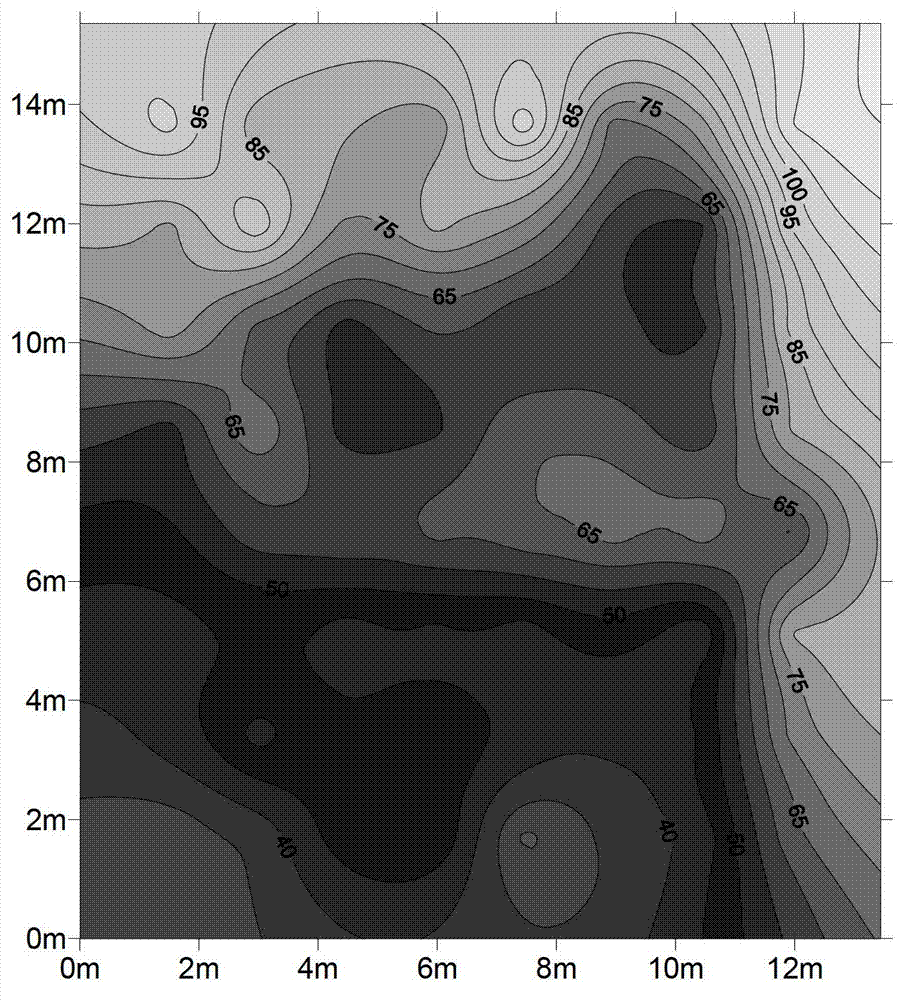

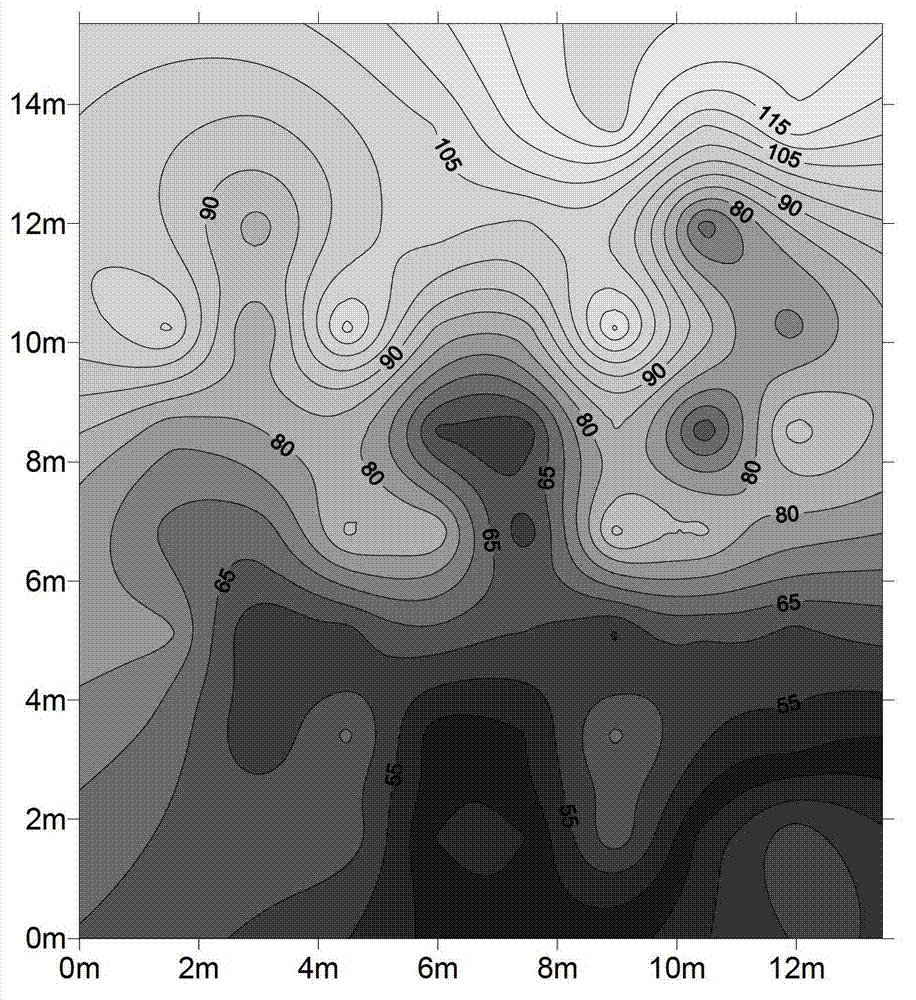

[0088] This embodiment detects the escape of ammonia under the condition of working condition 1 of the reactor A of the denitrification system. Using the method in the national standard "Electric Precipitator Performance Test Method" with the standard number GB / T13931-2002, the outlet flue section of the air preheater is uniformly distributed, and the air preheater is tested using a pitot tube and a parallel sampling instrument for smoke and dust. The cross-section of the outlet flue is subjected to isokinetic sampling, the smoke and dust in the flue gas are extracted, and after mixing evenly, the sample to be tested containing solid ammonia is obtained;

[0089] Weigh 1.0000g of the described sample to be tested containing solid ammonia, place it in a beaker, add 10g of deionized water thereto to obtain a solid ammonia sample solution to be tested;

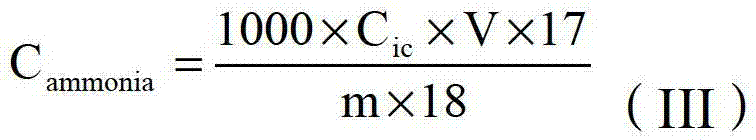

[0090] A hydrochloric acid solution with a mass fraction of 10% is placed in a potentiometric titrator, and then the pH value o...

Embodiment 3

[0098] According to the technical scheme of Example 2, the ammonia escape under the working condition 2 of the reactor A of the denitrification system is detected. The difference is that the mass of the sample to be tested containing solid ammonia in this example is 2.0000 g; the mass of deionized water is 100 g. The pH value of solid ammonia sample solution is between 6.1~6.7; The time of stirring is 1.5 hours, obtains denitrification system ammonia and escapes, and the result is as shown in table 1, and table 1 is embodiment 2~8 of the present invention and comparative example 1~ 7 to get the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com