Potassium ion embedded type vanadium pentoxide nanowire and preparation method thereof and application thereof

A vanadium pentoxide nanometer and vanadium pentoxide technology, which is applied in the field of potassium ion pre-embedded vanadium pentoxide nanowires and its preparation, can solve the problems of limiting practical applications, capacity fading, cycle performance degradation, etc. The effects of market promotion, high specific capacity, and super good rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of potassium ion pre-embedded type vanadium pentoxide nanowire, it comprises the steps:

[0036] 1) Weigh 0.7g SDS (sodium dodecyl sulfate) into 30ml deionized water, stir with a magnetic stirrer for 20 minutes, add 0.1818g V after the SDS is dissolved 2 o 5 Stir for another 20 minutes, then add 2ml of 1mol / L aqueous KOH solution therein, and continue stirring for 2 hours to obtain an orange-yellow aqueous solution;

[0037] 2) Transfer the aqueous solution obtained in step 1) to a 50ml reaction kettle, heat it in water at 180°C for 48 hours, and get a dark green product after taking it out;

[0038] 3) The product obtained in step 2) was centrifuged, washed 5 times with a mixed solution of absolute ethanol and deionized water (volume ratio 1:1), and dried in an oven at 80°C for 12 to 24 hours;

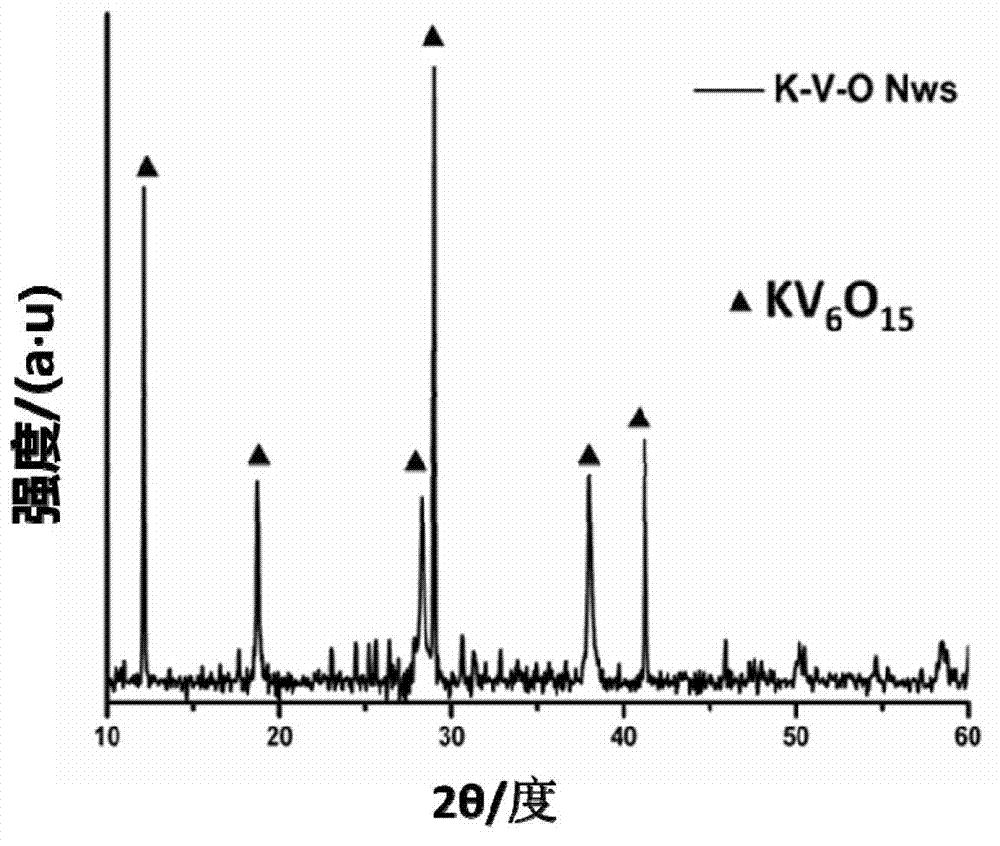

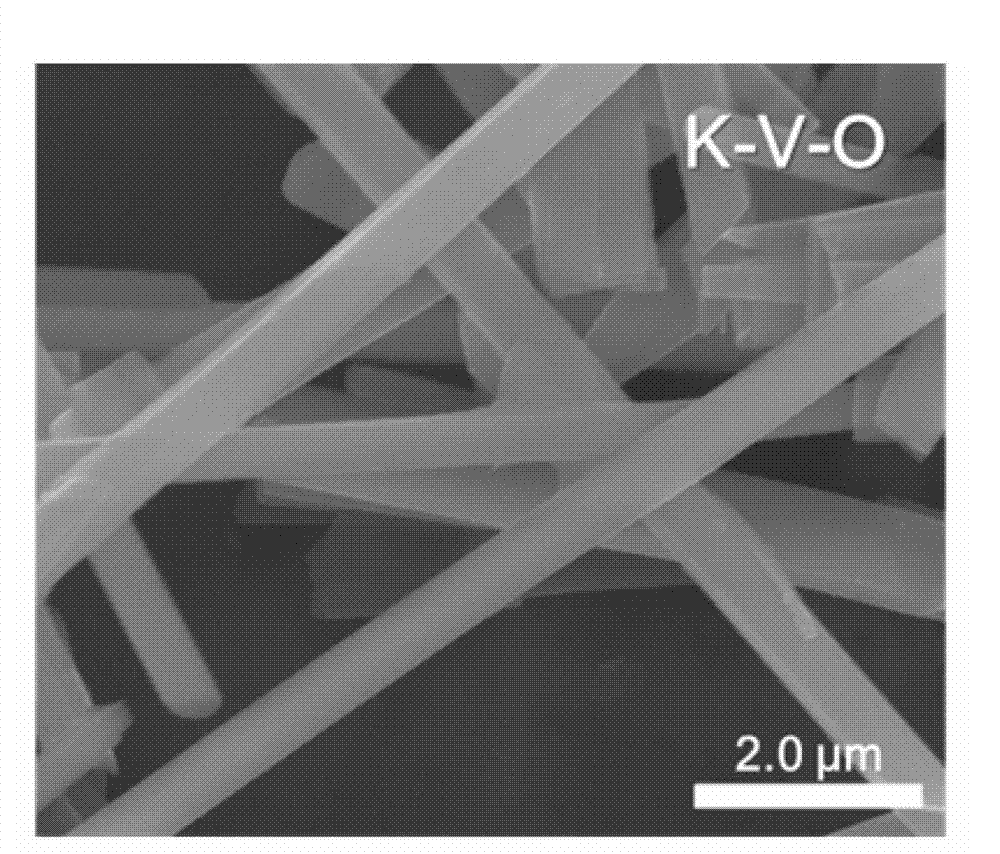

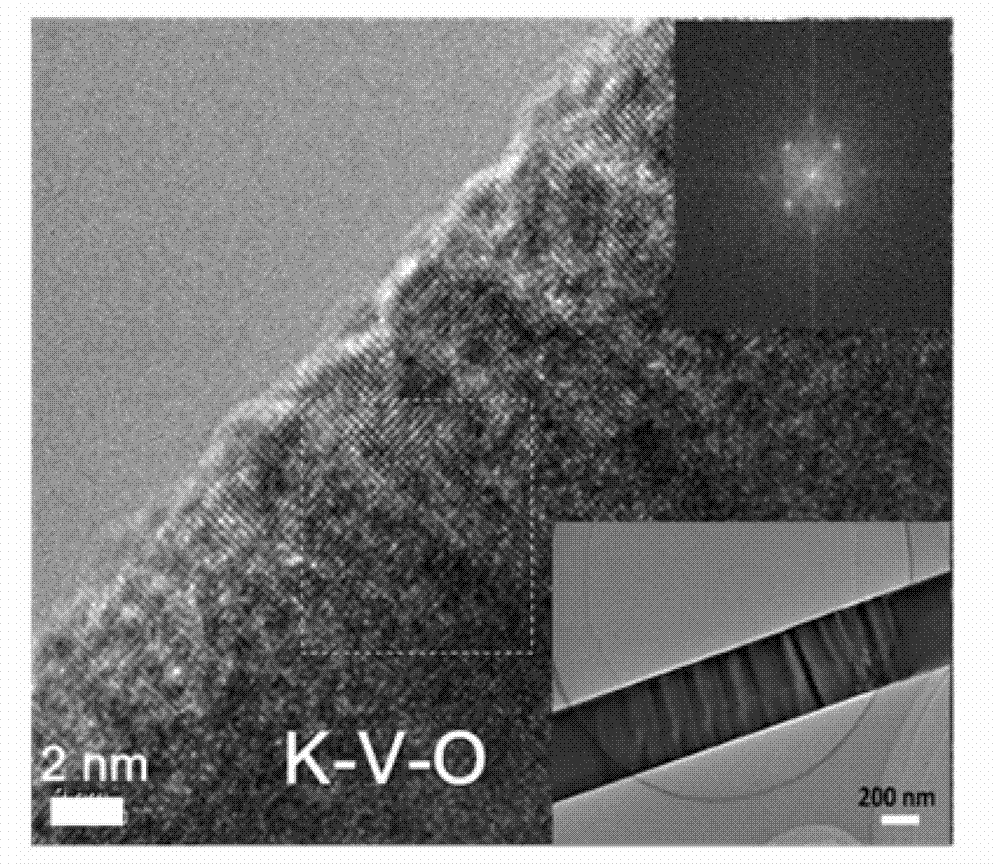

[0039] 4) The dried product obtained in step 3) was heat-treated in a muffle furnace at 600°C for 4 hours at a heating rate of 3°C / min, and a yellow-gr...

Embodiment 2

[0046] The preparation method of potassium ion pre-embedded type vanadium pentoxide nanowire, it comprises the steps:

[0047] 1) Weigh 0.7g SDS (sodium dodecyl sulfate) into 30ml deionized water, stir with a magnetic stirrer for 20 minutes, add 0.1818g V after the SDS is dissolved 2 o 5 Stir for another 20 minutes, then add 2ml of 1mol / L aqueous KOH solution therein, and continue stirring for 2 hours to obtain an orange-yellow aqueous solution;

[0048] 2) Transfer the aqueous solution obtained in step 1) to a 50ml reaction kettle, heat it in water at 180°C for 72 hours, and get a dark green product after taking it out;

[0049] 3) The product obtained in step 2) was centrifuged, washed 5 times with a mixed solution of absolute ethanol and deionized water (volume ratio 1:1), and dried in an oven at 80°C for 12 to 24 hours;

[0050] 4) The dried product obtained in step 3) was heat-treated in a muffle furnace at 500°C for 5 hours at a heating rate of 3°C / min, and a yellow-gr...

Embodiment 3

[0054] The preparation method of potassium ion pre-embedded type vanadium pentoxide nanowire, it comprises the steps:

[0055] 1) Weigh 0.1818g V 2 o 5 Add it to 30ml of deionized water, stir with a magnetic stirrer for 20 minutes, then add 0.5ml of 1mol / L KOH aqueous solution to it, and continue stirring for 24 hours to obtain an orange-yellow aqueous solution;

[0056] 2) Transfer the aqueous solution obtained in step 1) to a 50ml reaction kettle, heat it in water at 180°C for 120 hours, and get a dark green product after taking it out;

[0057] 3) The product obtained in step 2) was centrifuged, washed 5 times with a mixed solution of absolute ethanol and deionized water (volume ratio 1:1), and dried in an oven at 80°C for 12 to 24 hours;

[0058] 4) The dried product obtained in step 3) was heat-treated in a muffle furnace at 400°C for 8 hours at a heating rate of 3°C / min, and a yellow-green sample was obtained after heat treatment;

[0059] 5) Wash the sample obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com