MnOx catalyst for catalytically eliminating benzene series in air and preparation method of MnOx catalyst

A technology of catalysts and benzene series, which is applied in the field of benzene series catalytic combustion catalysts to achieve the effects of reducing catalyst costs, mild conditions and easy control, and good catalytic combustion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

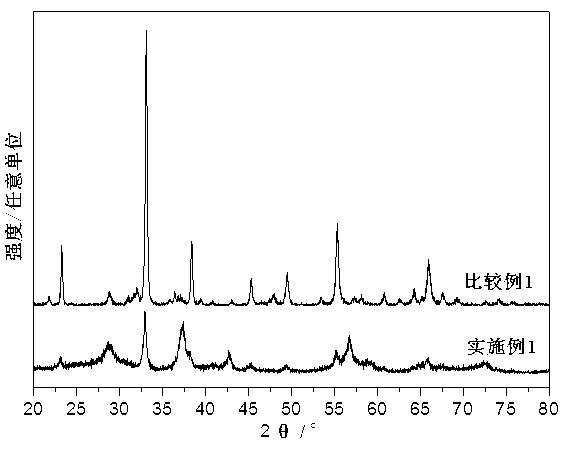

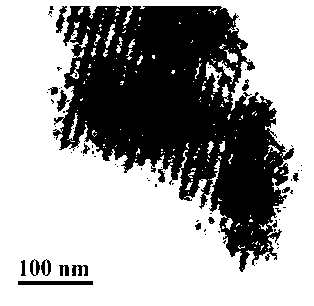

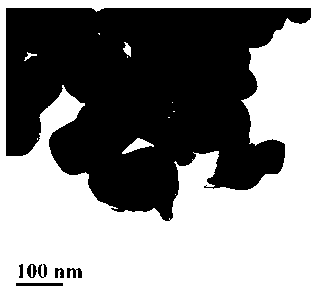

[0028] The MnO of this embodiment x The active component of the catalyst is MnO 2 and Mn 2 o 3 of mixed oxides, the MnO 2 and Mn 2 o 3 The mixed oxides have a mesoporous structure.

[0029] The MnO of this embodiment x The preparation method of catalyst comprises the following steps:

[0030] 1) One-time impregnation: impregnate the template agent in the absolute ethanol solution of manganese nitrate (the amount of the template agent and the total weight ratio of manganese nitrate is 1:1), evaporate the absolute ethanol solvent at 313 K under constant stirring conditions, The raw material was obtained, and the obtained raw material was dried at a constant temperature at 373 K for 24 h to obtain a dry material; the template agent is a mesoporous KIT-6 template agent, and its synthesis method refers to the following literature: F. Kleitz, S.H. Choi, R. Ryoo. Cubic Ia 3 d large mesoporous silica: synthesis and replication to platinum nanowires, carbon nanorods and car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com