A kind of numerical control cutting tool with craltin superlattice coating and preparation method thereof

A superlattice and cutting tool technology, applied in lathe cutting tools, coating, metal material coating technology, etc., can solve the problems that cannot meet the requirements of high-quality processed parts, high friction coefficient, poor wear resistance, etc. , to achieve the effects of improved friction coefficient and structural thermal stability, high toughness, and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

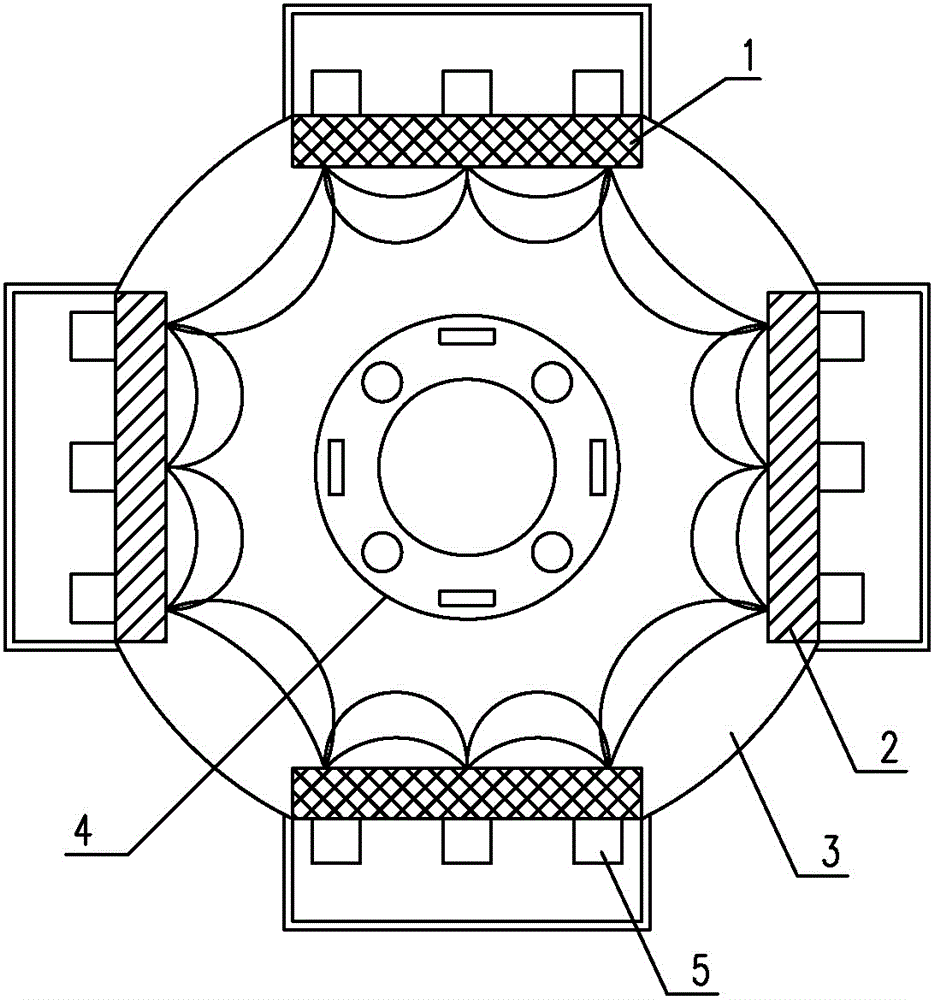

[0036] First, clean the prepared cemented carbide tool, clamp it on the sample holder, and start vacuuming. When the background vacuum is lower than 1.0×10 -3 At Pa, start heating, the temperature stabilizes at 300℃, the sample holder speed stabilizes at 4 rpm, Ar gas is introduced, and the water cooling device of the cathode target is turned on to start cooling, and the four cathode targets and the bias power supply are turned on at the same time. Keep the target power turned on at the lowest level, keep the bias voltage at 500V, and sputter cleaning for 30 minutes; after the glow cleaning, gradually reduce the substrate bias voltage to 100V, the element Ti target gradually increases the power, and the two alloy targets remain at the lowest power state . To deposit the metal Ti adhesion layer; after finishing this work, adjust the Ti target power, this target is the spectrum control target, after the spectrum control is turned on, the power is no longer adjusted, turn on the sp...

Embodiment 2

[0038] First, clean the prepared WC8Co series cemented carbide tool, clamp it on the sample holder, and start vacuuming. When the background vacuum is lower than 1.0×10 -3 At Pa, start heating, the temperature stabilizes at 350℃, the sample holder speed stabilizes at 3 rpm, Ar gas is introduced, and the water cooling device of the cathode target is turned on to start cooling, and the four cathode targets and the bias power supply are turned on at the same time. Keep the target power turned on at the lowest level, keep the bias voltage at 500V, and sputter cleaning for 30 minutes; after the glow cleaning, gradually reduce the substrate bias voltage to 100V, the element Ti target gradually increases the power, and the two alloy targets remain at the lowest power state . To deposit the metal Ti adhesion layer; after finishing this work, adjust the Ti target power, this target is the spectrum control target, after the spectrum control is turned on, the power is no longer adjusted, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com