Technological method for separating methanol, acetonitrile and benzene tertiary mixture

A process method and a mixture technology, applied in chemical instruments and methods, preparation of organic compounds, distillation purification/separation, etc., can solve difficult separations, cannot fully meet the separation requirements of ternary azeotropic systems, have no separation methods and Technology and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

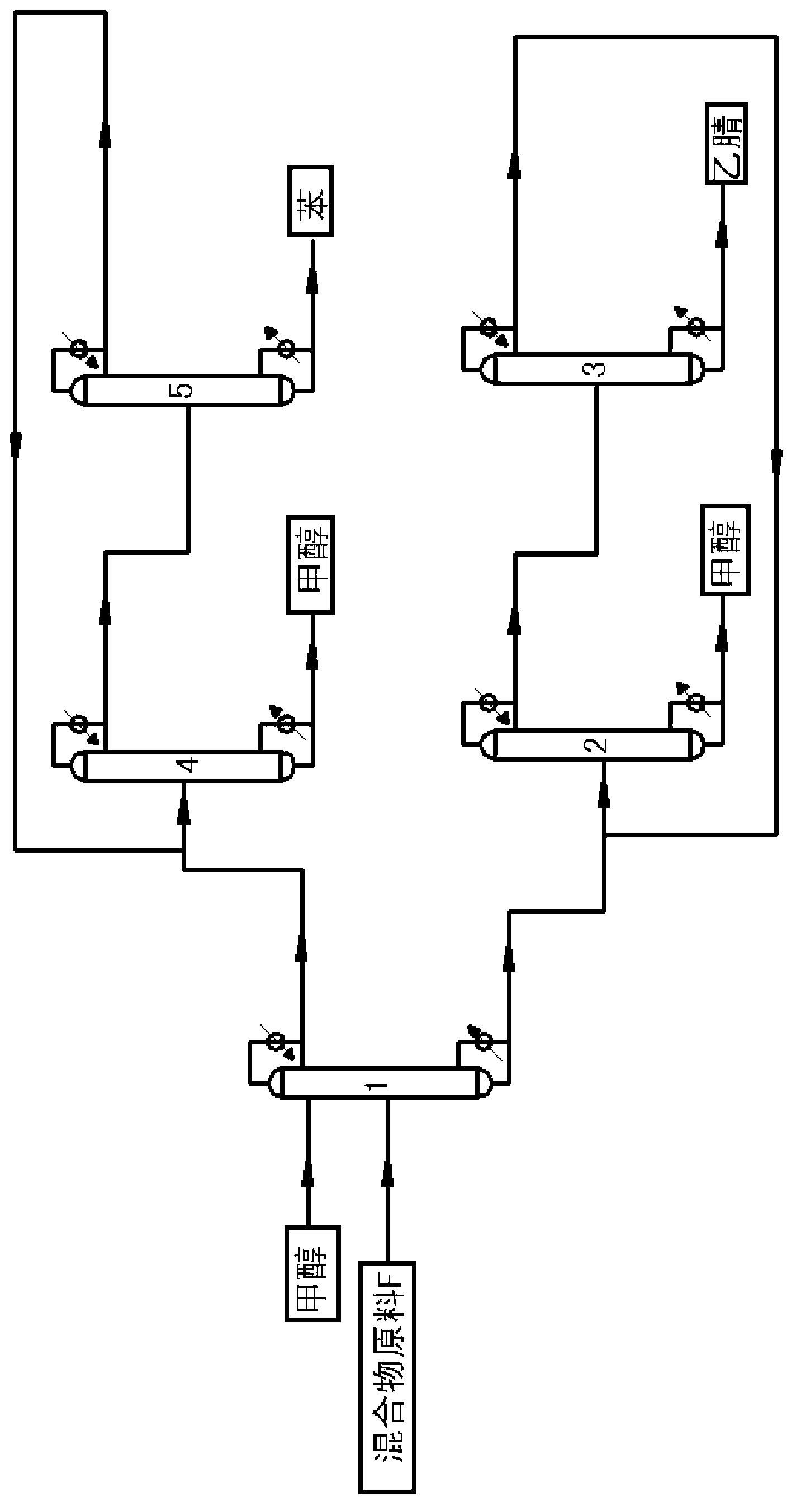

Image

Examples

Embodiment 1

[0033] Raw material composition: methanol: acetonitrile: benzene = 70%: 20%: 10% (mass concentration), the feed temperature of the raw material liquid is normal temperature, and the feed is fed from the 25th tray of the primary separation tower 1, and the feed flow rate is 1000kg / h; Methanol is introduced from the third tray of the primary separation tower, the feed temperature is normal temperature, and the flow rate is 1000kg / h. The output of light components at the top of the primary separation tower is 400kg / h, analyzed by gas chromatograph, methanol:benzene=78:22 (mass concentration); the output of heavy components at the bottom of the tower is 1600kg / h, analyzed by gas chromatograph Analysis, methanol: acetonitrile = 87:12 (mass concentration). The operating pressure of the primary separation tower 1 is normal pressure, the number of trays is 40, the top temperature is 60.0°C, the kettle temperature is 63.3°C, and the reflux ratio is 2.

[0034] The top component of th...

Embodiment 2

[0037] Other steps, parameter are with embodiment 1, difference is:

[0038] The operating pressure of the benzene tower 5 is normal pressure, the top temperature is 61.3° C., the kettle temperature is 80.6° C., the output of the tower top is 115 kg / h, and the output of benzene at the bottom of the tower is 15 kg / h.

[0039] The operating pressure of the acetonitrile column 3 is normal pressure, the top temperature is 61.5° C., the kettle temperature is 81.0° C., the output of the tower top is 660 kg / h, and the output of benzene at the bottom of the tower is 40 kg / h.

Embodiment 3

[0041] Other steps, parameter are with embodiment 1, difference is:

[0042] Raw material composition: methanol: acetonitrile: benzene = 60%: 30%: 10% (mass concentration), solvent flow rate is 1200kg / h. The output of light components at the top of primary separation tower 1 is 500kg / h, analyzed by gas chromatography, methanol:benzene=82:18 (mass concentration); the output of heavy components at the bottom of the tower is 1700kg / h, analyzed by gas chromatography Instrument analysis, methanol: acetonitrile = 82:18 (mass concentration). The top temperature of the primary separation tower 1 is 60.2°C, and the kettle temperature is 63.3°C.

[0043] The top temperature of the second low-pressure methanol tower 4 is 21.3°C, the kettle temperature is 28.3°C, the output of methanol and benzene binary mixture at the top of the tower is 150kg / h, and the output of methanol at the bottom of the tower is 350kg / h, and the mass concentration is 99.4 %. The top temperature of benzene tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com