Low-specific speed small mixed flow water turbine

A low specific speed, mixed-flow technology, applied in the field of water cooling tower systems, can solve the problems of insufficient increase, complex airfoil blade manufacturing process, unstable hydraulic performance, etc., to reduce the impact of air volume, good comprehensive synergy performance, The effect of superior hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: Taking the matching of the present invention with a water cooling tower system with a flow rate of 1000t / h as an example, the design parameters of the main components of the small Francis turbine of the present invention require the following:

[0028] The rotating speed of the small Francis turbine is 165r / min, and the working water head provided by the water cooling tower system is 10m.

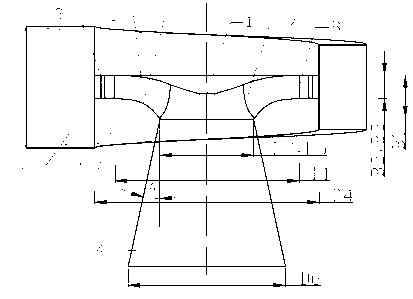

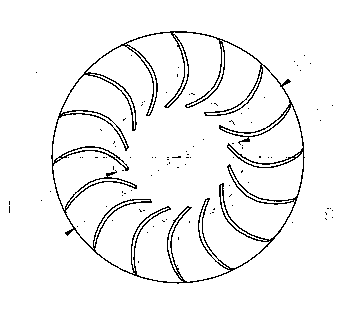

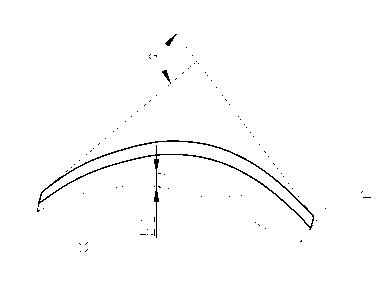

[0029]The height of the water turbine is 890mm, the maximum outer diameter is 1050mm, the inlet diameter of the runner (1) is 630mm, and the outlet diameter is 320mm. The ratio of the height (B0) of the runner (1) to the diameter D1 of the water inlet of the runner (1) is 0.3, and the diameter of the inlet 540mm, outlet diameter 320mm, the ratio of the water outlet diameter D2 of the runner (1) to the water inlet diameter D1 of the runner (1) is 0.6.

[0030] The radial section of the volute (2) is rectangular, the entrance section of the volute (2) is 530mm high and 31...

Embodiment 2

[0036] Embodiment 2: Taking the matching of the present invention with a water cooling tower system with a flow rate of 2000t / h as an example, the design parameters of the main components of the small Francis turbine of the present invention are as follows:

[0037] The rotating speed of the small Francis turbine is 155r / min, and the working water head provided by the water cooling tower system is 13m. .

[0038] The height of the turbine is 1220mm, the maximum outer diameter is 1440mm, the inlet diameter of the runner (1) is 805mm, and the outlet diameter is 440mm. The ratio of the height (B0) of the runner (1) to the diameter D1 of the water inlet of the runner (1) is 0.25, and the runner (1) The ratio of the diameter D2 of the water outlet of ) to the diameter D1 of the water inlet of the runner (1) is 0.54.

[0039] The radial section of the volute (2) is rectangular, the entrance section of the volute (2) is 710mm high and 355mm wide; the ratio of the width to the height...

Embodiment 3

[0045] Embodiment 3: Taking the matching of the present invention with a water cooling tower system with a flow rate of 3000t / h as an example, the design parameters of the main components of the small Francis turbine of the present invention are as follows:

[0046] The rotating speed of the small Francis turbine is 149r / min, and the working water head provided by the water cooling tower system is 14m.

[0047] The height of the turbine is 1410mm, the maximum outer diameter is 2000mm, the inlet diameter of the runner (1) is 1085mm, and the outlet diameter is 550mm. The ratio of the height (B0) of the runner (1) to the diameter D1 of the water inlet of the runner (1) is 0.3, and the runner (1 The ratio of the diameter D2 of the water outlet of ) to the diameter D1 of the water inlet of the runner (1) is 0.51.

[0048] The radial section of the volute (2) is rectangular, the entrance section of the volute (2) is 710mm high and 400mm wide; the ratio of the width to the height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com