Epoxy resin based molding material for sealing and electronic part or device provided with element sealed with this molding material

A technology of epoxy resin and molding materials, which is applied in the direction of epoxy resin glue, semiconductor/solid-state device parts, electrical components, etc., can solve the problems of labor and time, reduced packaging reliability, and reduced fluidity, and achieve reliable High performance, excellent reflow resistance, and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0223] The following examples illustrate the present invention in detail, but the present invention is not limited to these examples. In addition, unless otherwise specified, "%" is a mass standard.

[0224] Preparation of epoxy resin molding material for sealing

[0225] The following components were blended in parts by mass shown in the following Tables 1 to 8, and roll kneaded at a kneading temperature of 80°C and a kneading time of 10 minutes to prepare Examples 1 to 31 and Comparative Examples 1 to 10. 31 for sealing with epoxy resin molding compound. In addition, an empty column ("-") in the table indicates no fit.

[0226] As (A) epoxy resin, the following were used.

[0227] Epoxy resin 1: epoxy equivalent 196, the biphenyl type epoxy resin (Mitsubishi Chemical Corporation product name YX-4000) of melting point 106 degreeC.

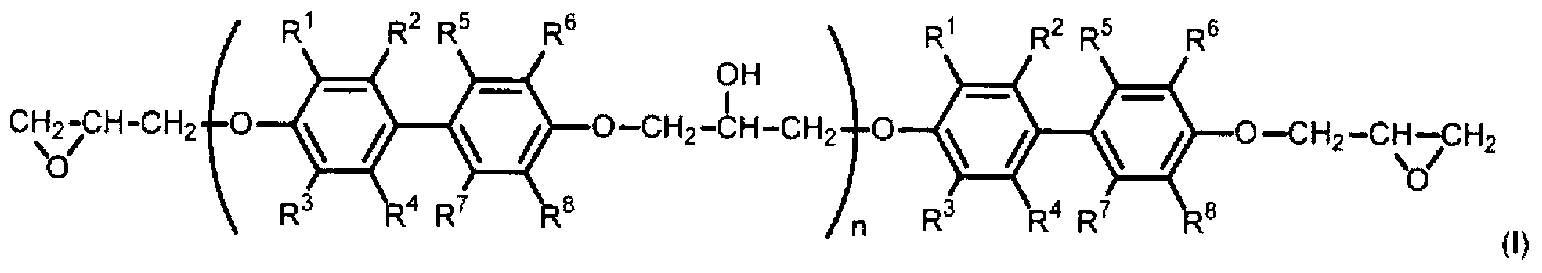

[0228] Epoxy resin 2: a biphenylene skeleton-containing phenol-aralkyl type epoxy resin having an epoxy equivalent of 241 and a softening poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com