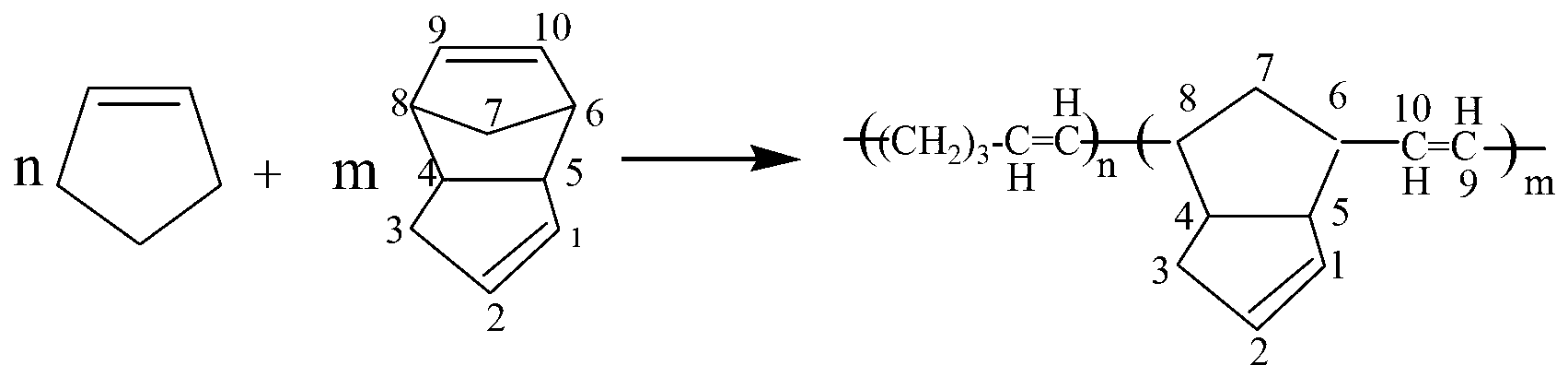

Ethylene propylene diene monomer and preparation method thereof

A technology of EPDM rubber and ethylene, which is applied in the field of EPDM rubber and its preparation, can solve the problems of environmental pollution and vulcanization speed, and achieve the effect of good processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

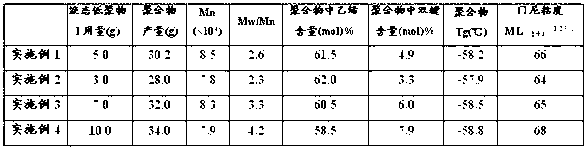

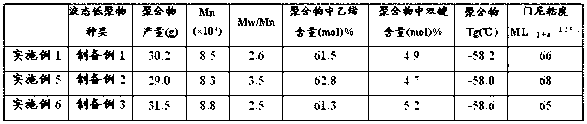

Examples

preparation example 1

[0029] Preparation of Cyclopentene-Dicyclopentadiene Liquid Low Molecular Weight Copolymer 1

[0030] In a 0.5L reactor replaced with nitrogen, 54g of cyclopentene, 10g of dicyclopentadiene, 256g of toluene, 0.03MWCl 6 Toluene solution 7.5mL, 0.1M tetrachlorophenol toluene solution 3.7mL, 1.0M 1-butene hexane solution 15.7mL, stir evenly and keep the reaction material temperature at 0°C, then add 0.1M triisobutyl Aluminum toluene solution 6.7mL, keep the temperature and react for 3.0hr, add 32mL ethanol solution containing 1% 2,6-di-tert-butyl-4-methylphenol into the reactor after the polymerization reaction to terminate the reaction, and then release the glue Coagulate with ethanol, and dry the obtained polymer in a vacuum oven at 50° C. to a constant weight for use. The weight of the polymer is 52 g.

[0031] Obtaining cyclopentene content in cyclopentene-dicyclopentadiene liquid low molecular weight copolymer is 84.5% (wt), and dicyclopentadiene content is 15.5% (wt), and ...

preparation example 2

[0033] Preparation of cyclopentene-dicyclopentadiene liquid low molecular weight copolymer 2

[0034] Preparation Example 1 was basically repeated, except that 48 g of cyclopentene and 16 g of dicyclopentadiene were added respectively, the polymerization reaction temperature was 15° C., and the 1.0 M 1-butene hexane solution was 6.7 mL.

[0035] Obtaining cyclopentene content in cyclopentene-dicyclopentadiene liquid low molecular weight copolymer is 79.5, and dicyclopentadiene content is 21.5% (wt), and trans structure content is 90% in polycyclopentene, polymer molecular weight is 9500, the molecular weight distribution is 1.8.

preparation example 3

[0037] Preparation of cyclopentene-dicyclopentadiene liquid low molecular weight copolymer 3

[0038] Preparation Example 1 was basically repeated, except that 60 g of cyclopentene and 4 g of dicyclopentadiene were added respectively, the polymerization reaction temperature was -10° C., and the 1.0 M 1-butene hexane solution was 30 mL.

[0039] Obtaining cyclopentene content in cyclopentene-dicyclopentadiene liquid low molecular weight copolymer is 93.0, and dicyclopentadiene content is 7.0% (wt), and trans polymerization structure content is 70% in the polycyclopentene, polymer molecular weight It is 1800, and the molecular weight distribution is 1.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com