Production method of easily-shaped high-strength medium-thickness steel plate

A production method and technology for thick steel plates, which are applied in heat treatment equipment, heat treatment process control, manufacturing tools, etc., can solve problems such as difficulty in meeting actual use requirements, uncontrolled yield ratio, poor cold bending performance, etc. The effect of satisfying the bending performance, reducing the yield ratio and improving the welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

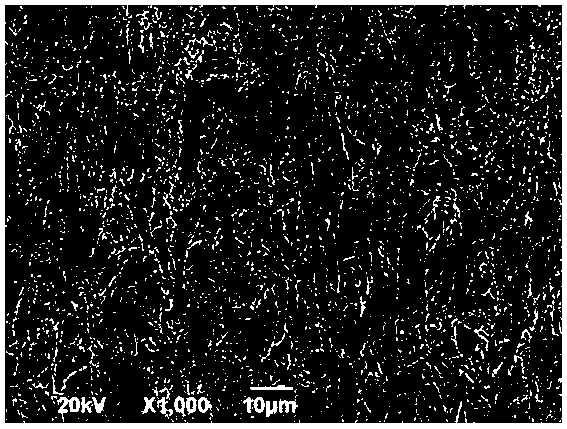

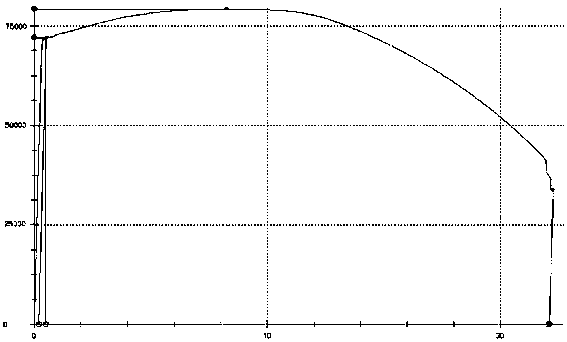

Image

Examples

Embodiment 1

[0026] Embodiment 1: 20mmQ890E steel plate production method

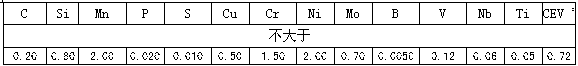

[0027] The chemical composition of the steel is shown in Table 3.

[0028] Table 3 Composition performance of 20mm Q890E steel plate %

[0029] chemical composition C Si mn P S Nb+V+Ti Cr + Mo Alt Pcm CEV Performance 0.08 0.20 1.69 0.013 0.001 0.105 0.91 0.032 0.25 0.58

[0030] Main process steps:

[0031] a. Sulfur content of molten iron S≤0.020%, temperature ≥1250°C, the slag must be cleaned before the molten iron enters the converter. Converter end point control target: C-T coordinated tapping, P 0.013%, S 0.019%; strict slag blocking and tapping, slag thickness ≤ 50mm, tapping time 6min, 1 / 5 of tapping is added with alloy, 2 / 5 of tapping is finished with alloy ; After the steel is tapped into the Al wire 260m deoxidation.

[0032] b. The electrification time of the molten steel in the LF furnace is 22 minutes, the total argon blowing time is 42 minutes, and the...

Embodiment 2

[0038] Embodiment 2: 30mm Q890E steel plate production method

[0039] The chemical composition of the steel is shown in Table 4.

[0040] Table 4 Composition performance of 30mm Q890E steel plate %

[0041] chemical composition C Si mn P S Nb+V+Ti Cr + Mo Alt Pcm CEV Performance 0.08 0.23 1.67 0.013 0.003 0.110 0.93 0.034 0.26 0.59

[0042] a. Sulfur content of molten iron S≤0.020%, temperature ≥1250°C, the slag must be cleaned before the molten iron enters the converter. Converter end point control target: C-T coordinated tapping, P 0.012%, S 0.016%; strict slag blocking, slag thickness ≤ 50mm, tapping time 6min, 1 / 5 of tapping is added with alloy, 2 / 5 of tapping is finished with alloy ; After the steel is tapped into the Al wire 300m deoxidation.

[0043] b. The electrification time of the molten steel in the LF furnace is 27 minutes, the total argon blowing time is 44 minutes, and the white slag retention time is 15 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com