Dye adsorption device, dye adsorption method, and substrate treatment apparatus

A substrate processing device and adsorption device technology, applied in electrolytic capacitors, photovoltaic power generation, electrical components, etc., can solve problems such as impracticality and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

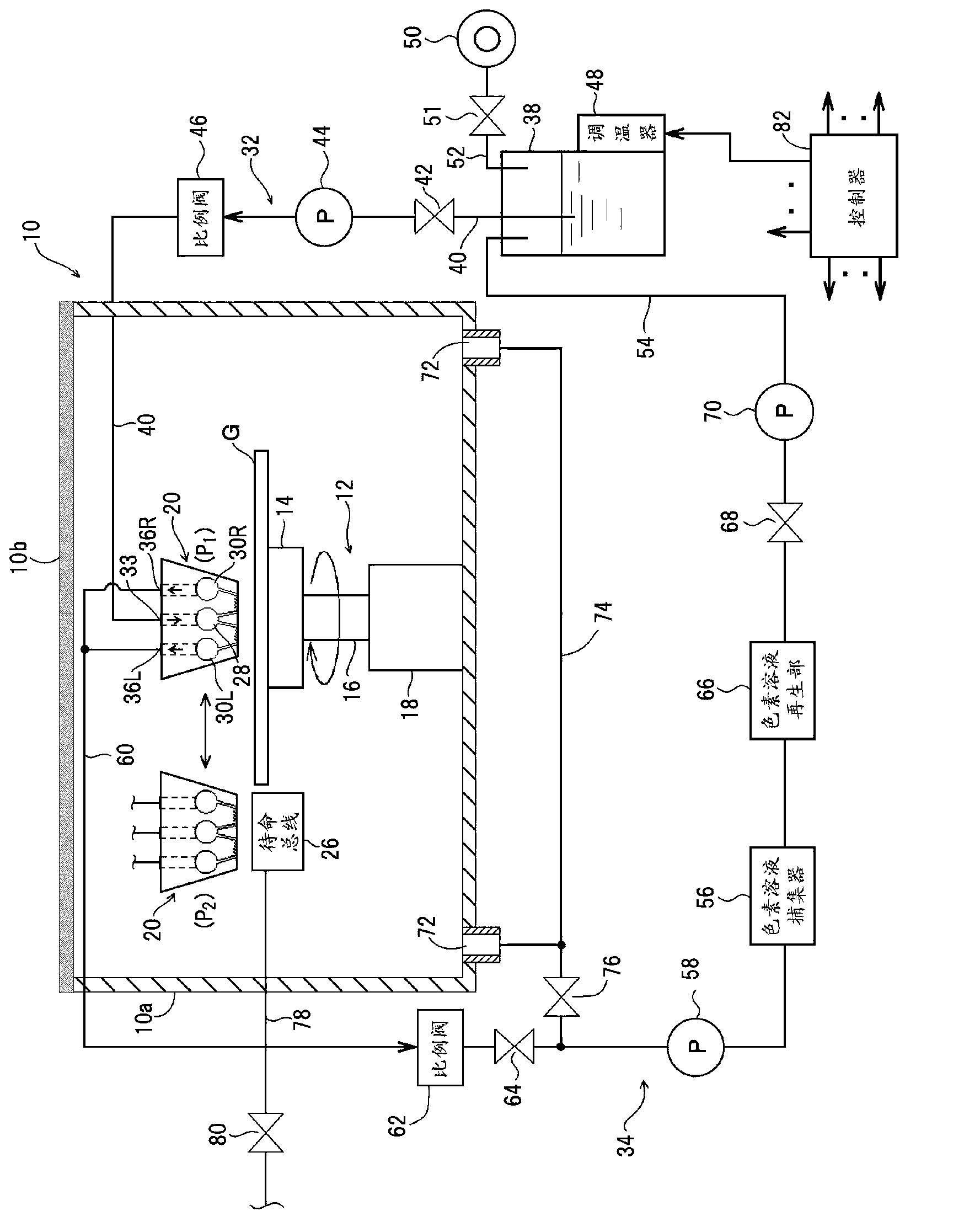

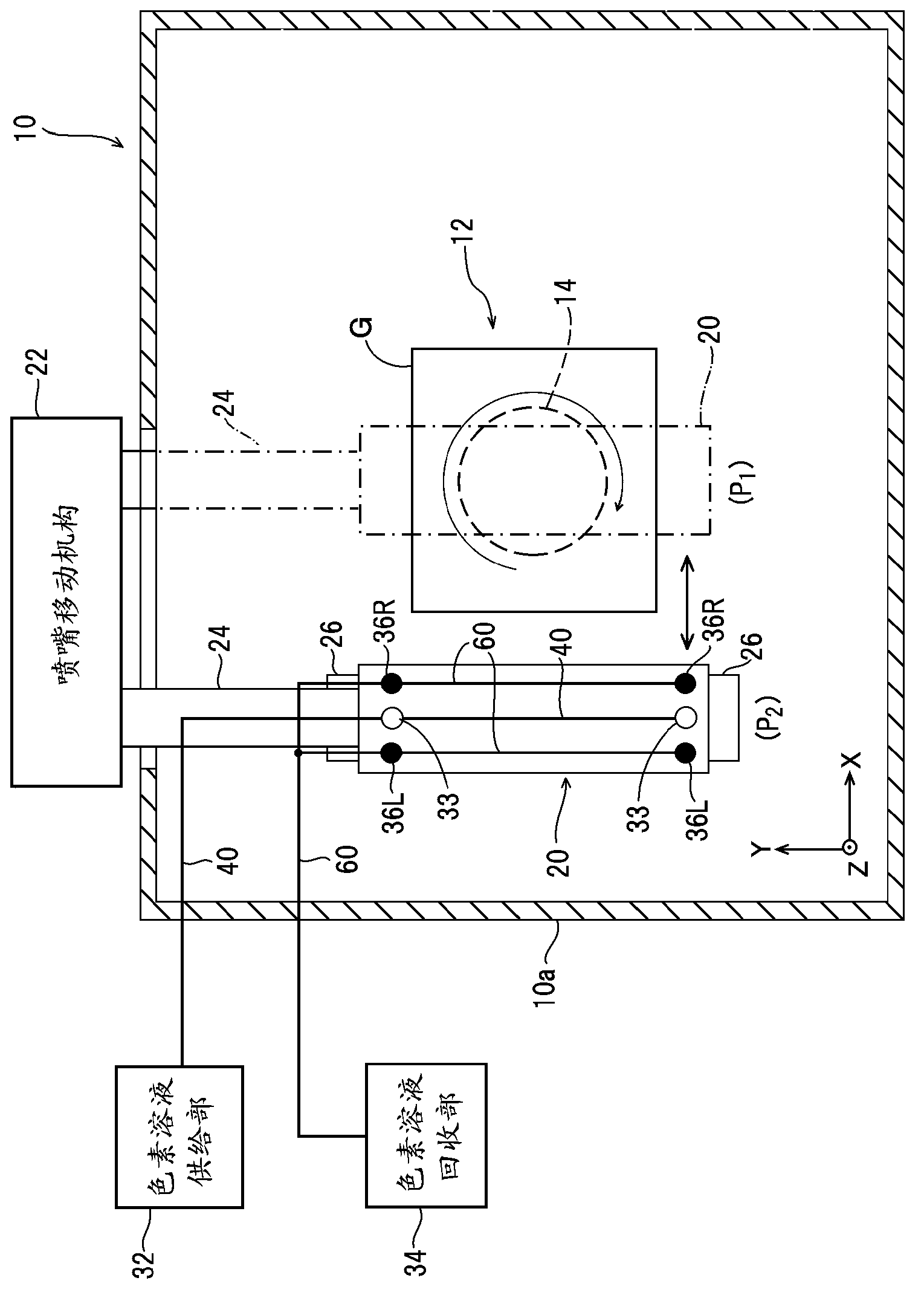

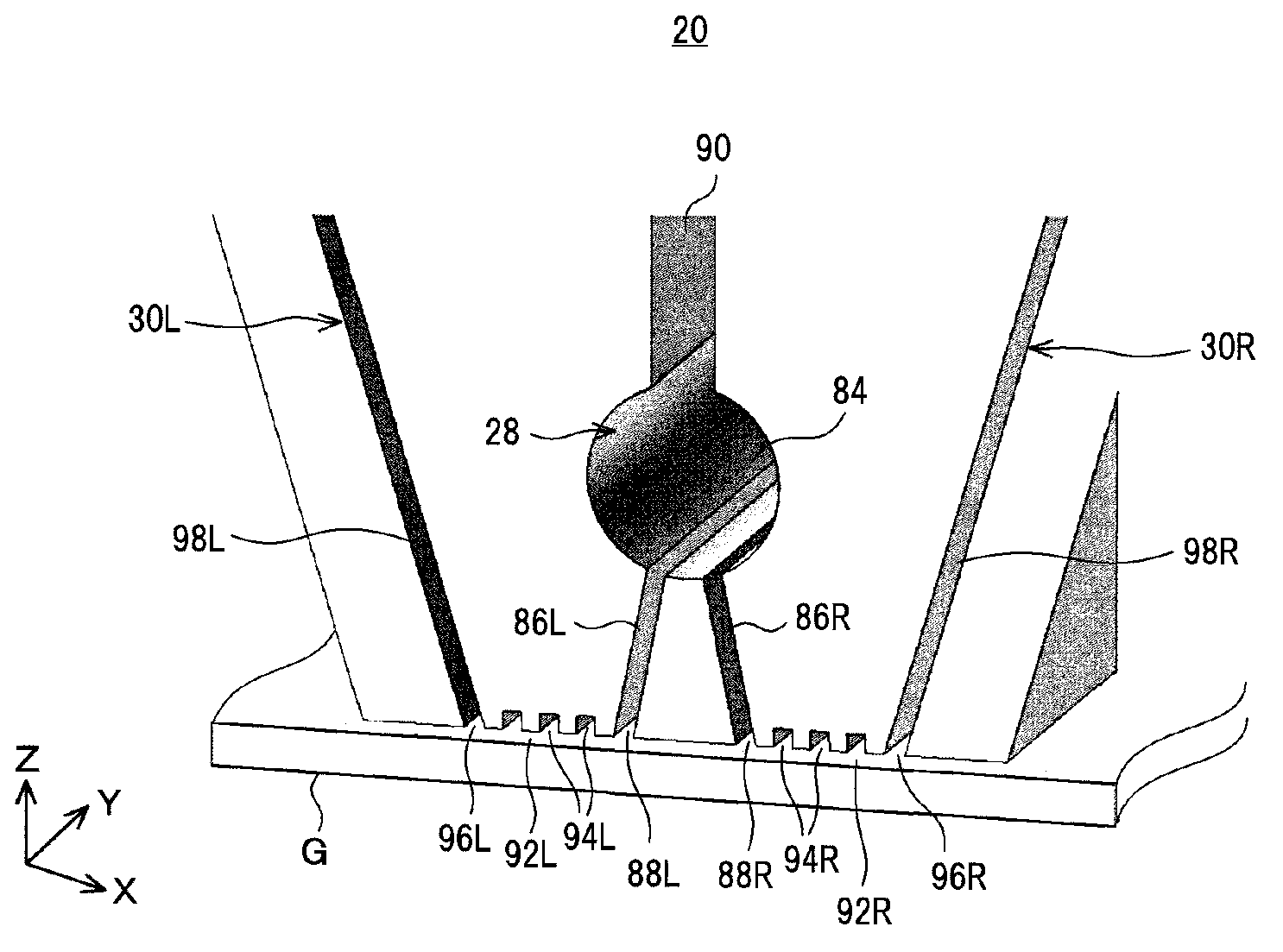

[0045] figure 1 and figure 2 The overall configuration of the dye adsorption device in one embodiment of the present invention is shown in the figure. For example, in the manufacturing process of a dye-sensitized solar cell, the dye adsorption device is used in the step of adsorbing a sensitizing dye to a porous semiconductor layer as a single wafer (leaf). In this case, the transparent substrate 208 on which the transparent electrode 200 and the porous semiconductor layer 204 are formed ( Figure 20 ) as the processed substrate G in the dye adsorption device.

[0046] Wherein, the transparent substrate 208 is made of, for example, transparent inorganic materials such as quartz and glass, or transparent plastic materials such as polyester, acrylic, and polyimide. The transparent electrode 200 is, for example, made of fluorine-doped SnO 2 (FTO), or indium tin oxide (ITO). In addition, the porous semiconductor layer 204 is made of TiO 2 , ZnO, SnO 2 Made of metal oxides....

Embodiment approach 2

[0079] Figure 8 The whole structure of the substrate processing apparatus in one Embodiment of this invention is shown in figure. In the figure, for the above-mentioned first embodiment ( Figure 1 to Figure 7 ) parts with the same configuration or function are given the same reference numerals.

[0080] This substrate processing apparatus fully includes the dye adsorption device in the first embodiment described above as a dye adsorption unit, and further includes a rinse unit and a drying unit. The rinse unit in this embodiment is configured to include a substrate holding unit 12 , a nozzle 20 , a rinse liquid supply unit 110 , and a rinse liquid recovery unit 112 . Among them, the substrate holding unit 12 and the nozzle 20 are used not only in the dye adsorption unit but also in the rinse unit and the drying unit. In addition, the suction pump 58, the vacuum line 60, the electromagnetic proportional valve 62, the electromagnetic on-off valve 64, and the suction pump 58...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com