Radiation synthetic method for high-speed selective adsorption material

A technology of adsorption materials and synthesis methods, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as no patent application, and achieve environmental load reduction, strong controllability, comprehensive economy significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use polyethylene or polypropylene resin particles (average diameter of about 100μ) as the polymer substrate, put 10g of the above material into a nitrogen-containing PE bag, and use a high-energy electron accelerator to irradiate to produce activity that can be used for grafting reactions. Free radicals; the irradiation conditions are irradiation voltage 2MeV, irradiation dose 200 kGy, dose rate 10 kGy / pass, and the above-mentioned particles after irradiation are immediately put into a mixture of 35% GMA, 3.5% polyoxyethylene sorbitan monolaurate and In the emulsion reaction system composed of 61.5% water, the emulsification reaction system of GMA monomer was continuously blown with nitrogen for 30 minutes before use to discharge the oxygen in the water. The graft polymerization reaction was carried out at 50°C for 2h. The grafted polymer obtained under the above conditions: the grafting ratio of the polyethylene substrate is 200%, or the grafting ratio of the polypropy...

Embodiment 2

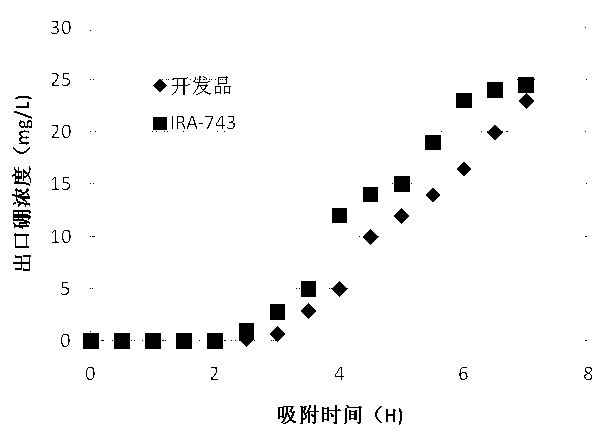

[0027] Embodiment 2: two kinds of adsorption resin dynamic adsorption characteristic comparisons

[0028] Fill 7.5ml of the polyethylene-based adsorption resin prepared in Example 1 into an adsorption column in a wet state. The size of the adsorption column is φ16×38mm, and evaluate its dynamics by injecting a pre-prepared boron-containing aqueous solution. Adsorption characteristics, the concentration of boron-containing aqueous solution is 26 mg / L, and the flow rate of 2.5 ml / min passes through the resin bed; for the convenience of comparison, at the same time, the existing cross-linked polystyrene resin substrate, N-methyl- Glucosamine is the commercial resin IRA-743 with adsorption functional group, and its adsorption characteristics were evaluated according to the same experimental conditions.

[0029] Dynamic adsorption evaluation experimental conditions: adsorption column size φ16×38mm, resin volume 7.5ml, boron-containing aqueous solution concentration 26mg / L, flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com