Heating system for garage type dry fermentation and operation control method thereof

A technology of dry fermentation and dry anaerobic fermentation, which is applied in the field of new energy development and energy-saving applications, to achieve the effects of reducing manpower investment, ensuring normal operation, and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

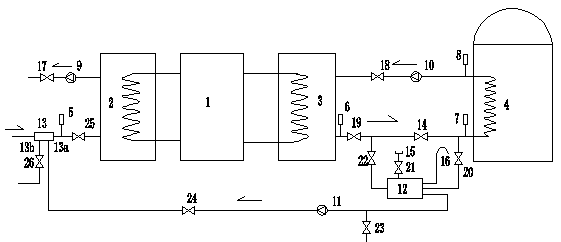

[0034] Embodiment 1: The effective volume of the garage type dry fermentation tank that this example adopts is 120m 3 . The pool body is a cube, the internal size is (length x width x height) 10m x 4m x 3m, the pool wall is concrete with a thickness of 20cm, the bottom of the pool is the ground, and a polyurethane insulation board with a thickness of 70mm is used as the thermal insulation material on the pool wall. The top of the fermentation tank adopts 50mm polyurethane insulation board as thermal insulation material, and the coverage is 50m 2 , Lay a heating coil heat exchanger along the inner wall of the fermentation tank, the heating coil adopts PERT pipe with a diameter of 25×2.0, the total length of the coil is 125m, and the distance between the coils is 150mm. In order to speed up the heat transfer of the feed liquid and improve the heating effect, the fermentation tank adopts the circulating biogas slurry spraying method.

[0035] The selected heat pump host 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com