3-5-micron waveband intermediate infrared solid laser

A solid-state laser and wavelength band technology, applied in the optical field, can solve the problems of low output power and poor brightness, achieve high stability, increase pump power, and improve beam quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

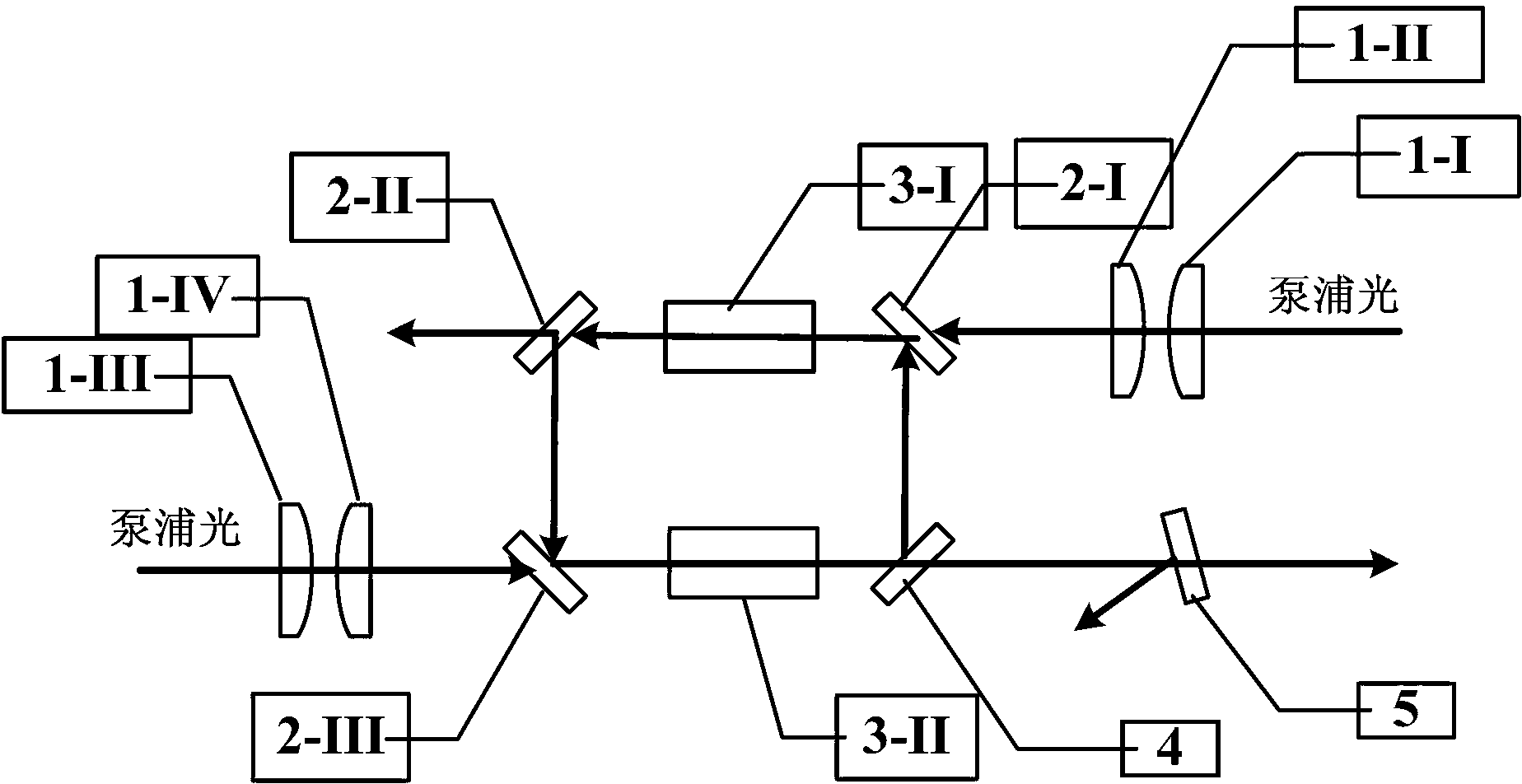

[0013] Specific implementation mode one: the following combination figure 1 Describe this embodiment mode. A 3-5 μm band mid-infrared solid-state laser described in this embodiment mode includes No. 1 plano-convex lens 1-I, No. 2 plano-convex lens 1-II, No. 3 plano-convex lens 1-III, and No. 4 plano-convex lens 1-III. Convex lens 1-IV, No. 1 input mirror 2-I, No. 1 plane mirror 2-II, No. 2 input mirror 2-III, OPO output mirror 4, lens 5, No. 1 optical parameter oscillating crystal 3-I and No. 2 optical parameter Oscillating crystal 3-II;

[0014] The convex surfaces of the No. 1 plano-convex lens 1-I and the No. 2 plano-convex lens 1-II are opposite to form a No. 1 coupling system; No. coupling system;

[0015] The No. 1 input mirror 2-I, the No. 1 plane mirror 2-II, the No. 2 input mirror 2-III and the OPO output mirror 4 form an optical parametric oscillation resonant cavity;

[0016] The first pump laser incident to the first coupling system is coupled by the first coupl...

specific Embodiment approach 2

[0019] Specific implementation mode two: the following combination figure 1 Describe this embodiment mode. This embodiment mode will further explain Embodiment 1. The No. 1 optical parametric oscillator crystal 3-I and the No. 2 optical parametric oscillator crystal 3-II described in this embodiment mode are the same type of crystals. BYZGR 2 The crystal is coated with 2μm and 3-5μm anti-reflection coatings on both the light incident surface and the transmission surface of the crystal.

specific Embodiment approach 3

[0020] Specific implementation mode three: the following combination figure 1 Describe this embodiment, this embodiment will further explain Embodiment 1, the No. 1 input mirror 2-I, the No. 1 plane mirror 2-II and the No. Transparent film, the other side is coated with 2μm high-transparency and 3-5μm high-reflection film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com