Pulse forming network based on double-capacitor structure

A dual-capacitor and capacitor technology, applied in the field of high-voltage pulse square wave generation and pulse formation network, can solve the problems of low energy storage density, poor reliability, and high impedance, and achieve high energy storage density, compact structure, and reduced level effect of numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

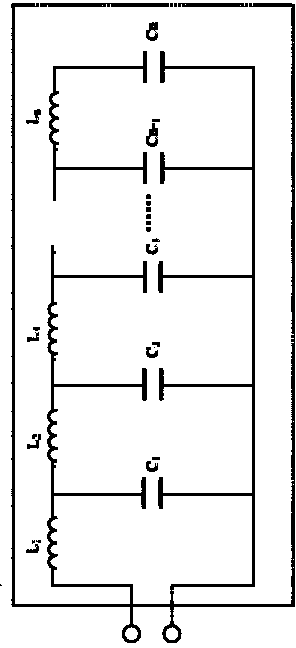

[0029] Such as figure 1 As shown, the circuit diagram is the circuit used in the prior art. The LC loop network series used in the circuit is generally in the range of 6-10. The capacitors in the network generally use ceramic capacitors and film capacitors, because these two capacitors are affected by traditional technology. Limitation, short life, high impedance, low energy storage density, poor reliability, large volume, and bulky, the general volume of the pulse forming network that is often made into a finished product is 1000mm long × 150mm wide × 150mm high, and the volume of the pulse forming network under this volume Too large, very inconvenient for transportation and practicality, and cannot meet the requirements of the miniaturization of the current process.

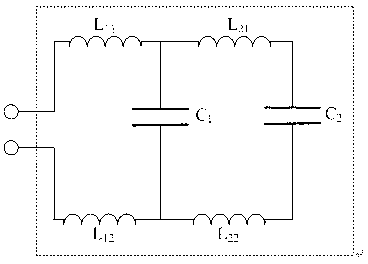

[0030] Such as figure 2 As shown, the circuit diagram is the circuit of the present invention. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com