Graphite dust collector

A technology of graphite dust and dust removal device, which is applied in the direction of combination device, dispersion particle separation, chemical instruments and methods, etc., can solve the problems of general dust removal effect, difficult to remove, safety threats of workshop vehicles and pedestrians, etc., to avoid pollution and human health Hazardous, good follower lubrication and cooling, good dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

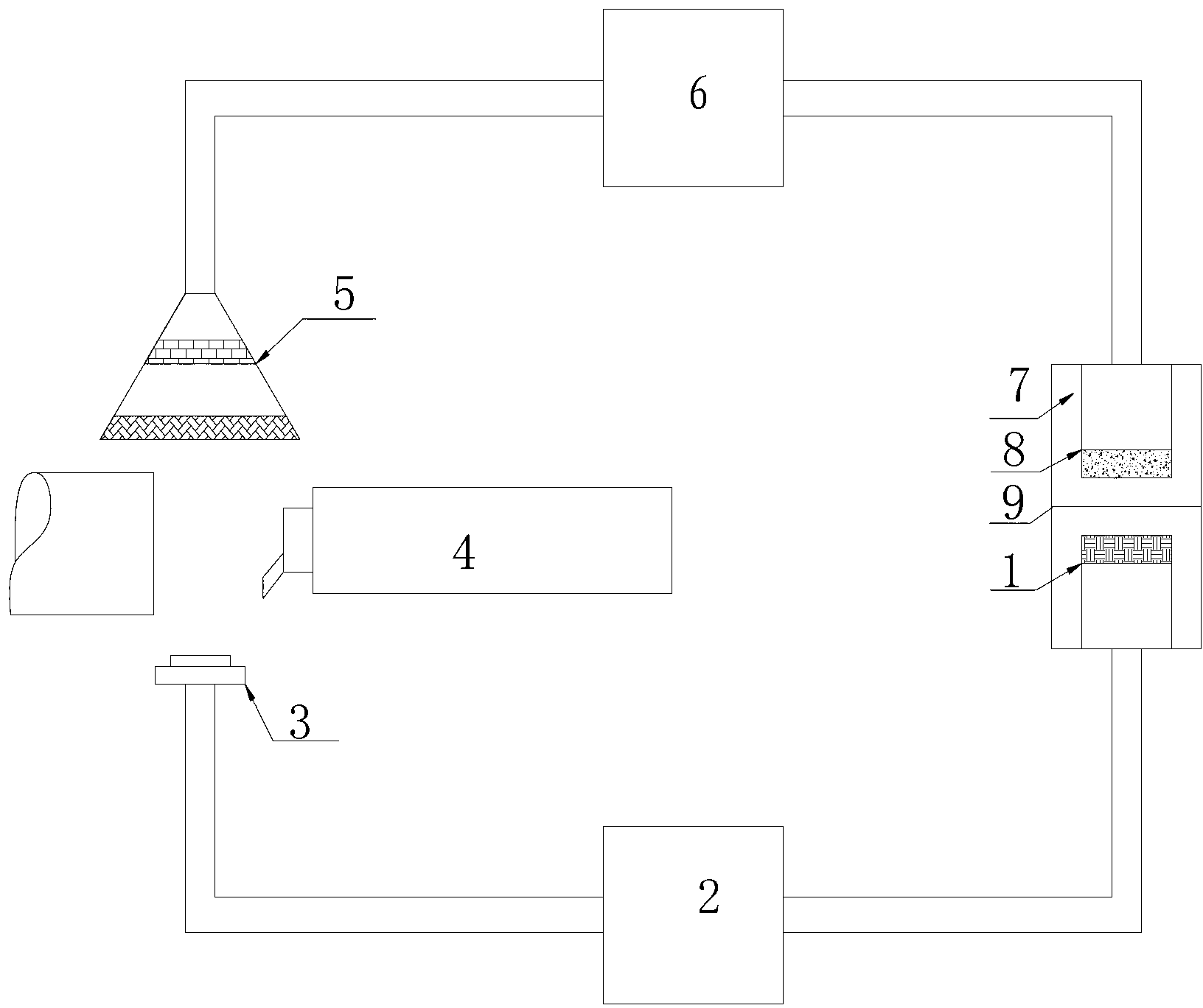

[0017] In order to make the innovative features, implementation means, functional principles and objectives achieved by the present invention easier to understand, the present invention will be further described below in conjunction with specific embodiments and schematic diagrams.

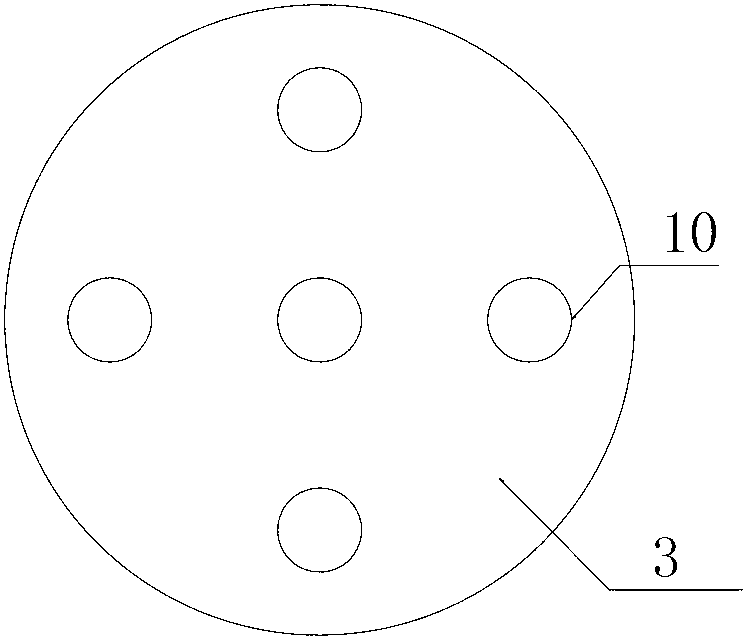

[0018] Referring to the schematic diagram, an embodiment of the present invention provides a graphite dust removal device, which includes a chip fluid filter 1 for filtering the chip fluid entering the chip fluid pump 2; the filtered chip fluid passes through the chip fluid pump to form high-pressure chips The liquid enters the self-rotating atomizing nozzle 3 to form an atomized chip liquid; the universal chip liquid pipe can adjust the position and direction of the nozzle; the atomized chip liquid captures the graphite dust that is free near the processing surface and is sucked by the vacuum cleaner 5 , and the aerosol mixture is preliminarily treated through the filter screen and the magnetized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com