Polycarboxylic acid-type high-water reducing and slump resistant early strength pumping aid

A polycarboxylate-based, early-strength type technology, which is applied in the field of polycarboxylate-based high-water-reducing, slump-preserving, early-strength, high-efficiency pumping agents, can solve the problem that the performance cannot meet the construction requirements, the early strength of concrete is affected, and the cost of concrete cannot be reduced To achieve the effect of excellent long-term durability of concrete, wide adaptability of cement and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

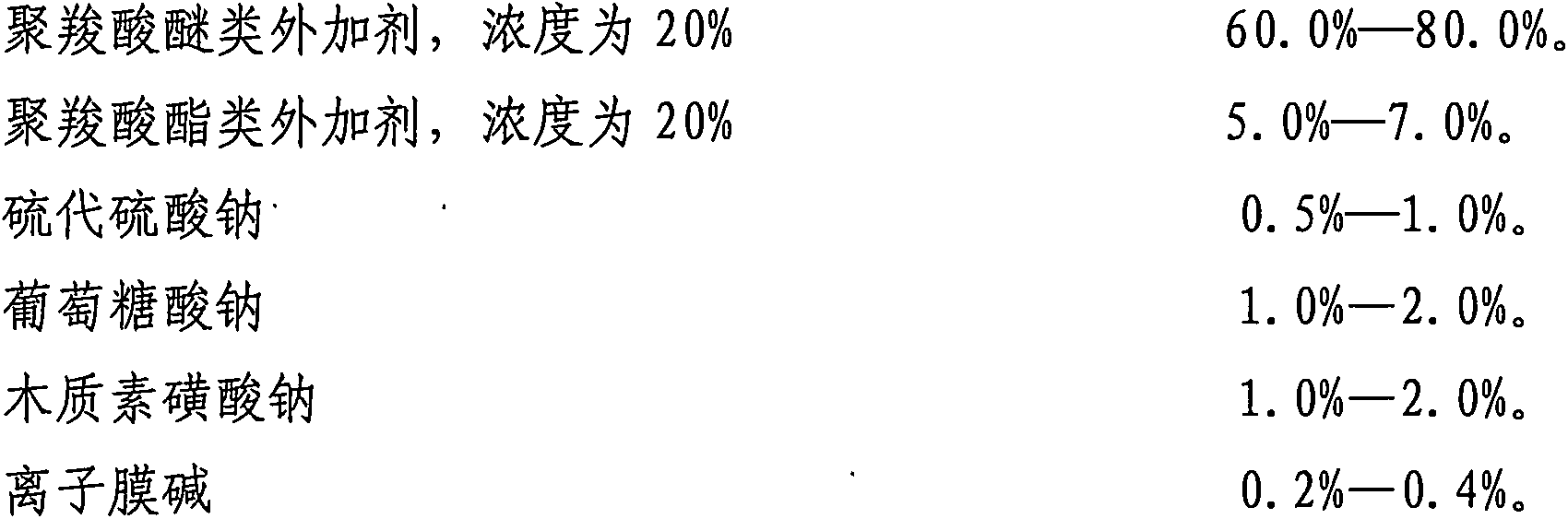

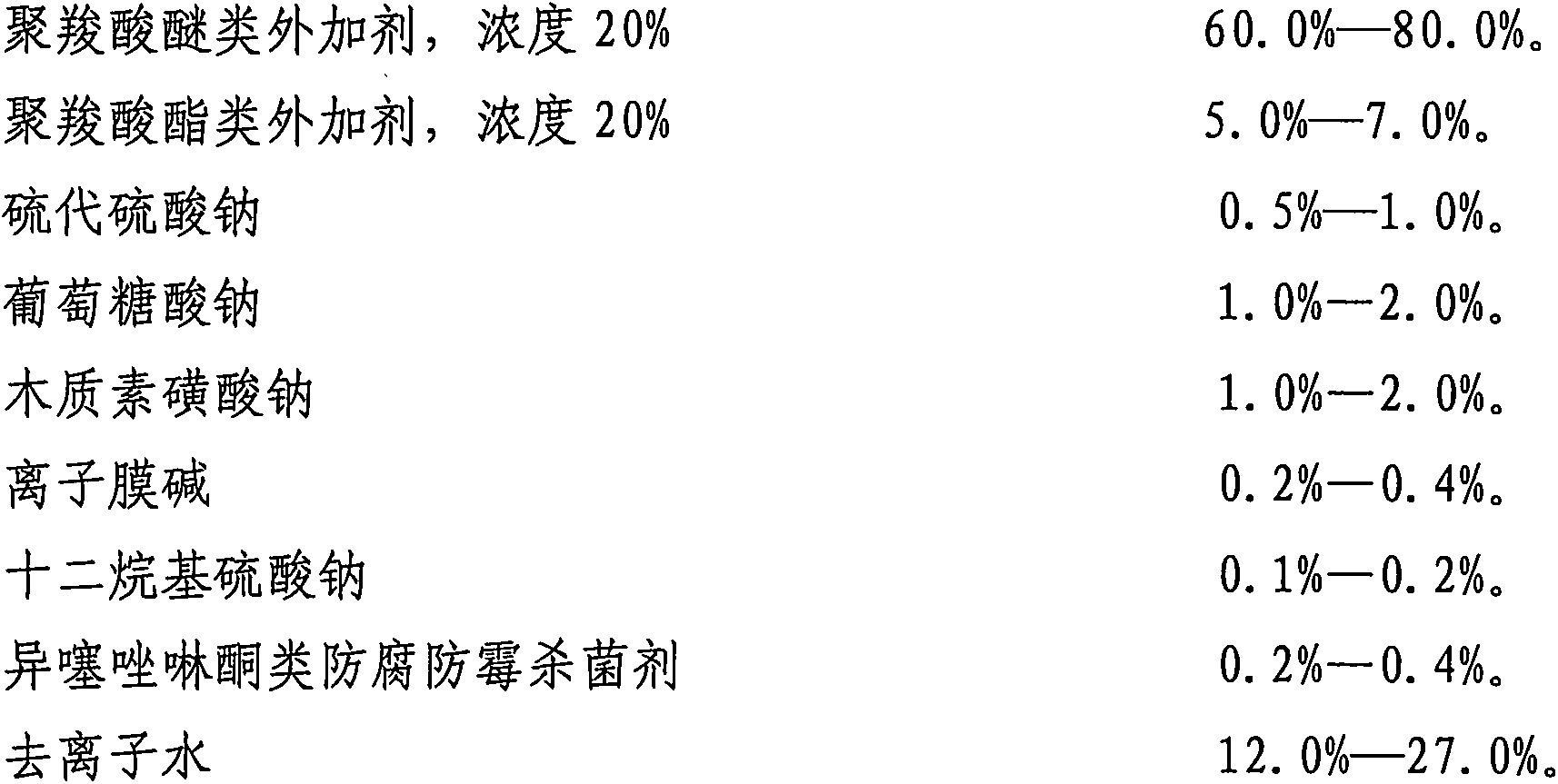

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Add 20.8kg of deionized water with the above composition and ratio into the reaction pot and heat up to 40°C-50°C, add 70kg of polycarboxylate ether admixture, add 5kg of polycarboxylate admixture, add Sodium thiosulfate 0.6Kg, keep the temperature and stir for 30 minutes to form a synthetic product with a specific structure. Then add 1.5kg of sodium gluconate and 1.5kg of sodium lignosulfonate to compound and stir for 30 minutes. After cooling to room temperature, add 0.3kg ion-exchange membrane alkali to adjust the pH value to 6-8, add 0.1kg sodium lauryl sulfate, 0.2kg isothiazolinone anti-corrosion, mildew-proof and fungicide, and continue stirring for 30 minutes , which is the finished product.

Embodiment 2

[0020] Example 2: Add 25.3kg of deionized water with the above composition and ratio into the reaction pot and heat up to 40°C-50°C, add 62kg of polycarboxylate ether admixture, add 7kg of polycarboxylate admixture, add Sodium thiosulfate 0.8Kg, keep the temperature and stir for 30 minutes to form a synthetic product with a specific structure. Then add 2.0kg of sodium gluconate and 2.0kg of sodium lignosulfonate to compound and stir for 30 minutes. After cooling to normal temperature, add 0.4kg ion-exchange membrane alkali to adjust the pH value to 6-8, add 0.2kg of sodium lauryl sulfate, 0.3kg of isothiazolinone anti-corrosion, mildew-proof and fungicide, and continue stirring for 30 minutes , which is the finished product.

Embodiment 3

[0021] Example 3: Add 14.0kg of deionized water with the above composition and ratio into the reaction pot and heat up to 40°C-50°C, add 75kg of polycarboxylate ether admixture, add 6kg of polycarboxylate admixture, add Sodium thiosulfate 0.8Kg, keep the temperature and stir for 30 minutes to form a synthetic product with a specific structure. Then add 1.5 kg of sodium gluconate and 2.0 kg of sodium lignosulfonate to compound and stir for 30 minutes. After cooling to normal temperature, add 0.3kg ion-exchange membrane alkali to adjust the pH value to 6-8, add 0.2kg of sodium lauryl sulfate, 0.2kg of isothiazolinone anti-corrosion, anti-mold and fungicide, and continue stirring for 30 minutes , which is the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com