Ceramic sanitary ware prepared from waste ceramic and preparation method thereof

A technology of sanitary ceramics and waste porcelain powder, applied in the field of sanitary ceramics, which can solve the problems of high environmental protection costs, difficult weathering and difficult disposal of ceramic fragments, achieve good product performance, overcome poor thermal shock resistance, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing sanitary ceramics from waste porcelain, comprising the steps of:

[0020] (1) Take sanitary ceramic waste porcelain, whose chemical composition is shown in Table 1. After crushing, roll mill for 18 hours, and the fineness is controlled at 0-2 μm, accounting for 15%, 2-10 μm, accounting for 60%, and 10-75 μm, accounting for 25%.

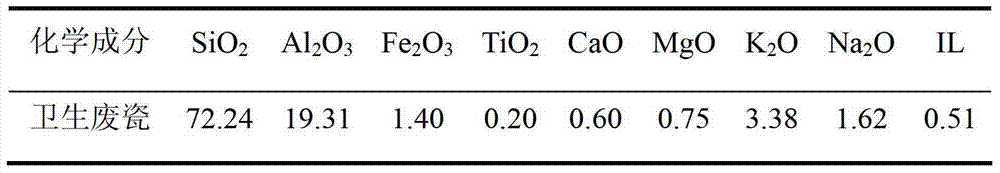

[0021] Table 1 Composition of sanitary waste porcelain from a sanitary ceramics factory in Chaozhou

[0022]

[0023] (2) Take black soil, Xikeng mud, and ball soil respectively. After crushing, according to the ball: material: water weight ratio of 1:1:1, ball mill for 3 hours, the fineness is controlled at 0-10 μm, accounting for 60%, and the largest grain The diameter is less than 250 μm. .

[0024] (3) The maximum particle size of albite and burnt talc after ball milling is less than 150 μm.

[0025] (4) Weigh 150g of waste porcelain powder, and other raw materials are weighed according to the mass ratio of wast...

Embodiment 2

[0029] The difference between this embodiment and embodiment 1 is:

[0030] The mass ratio of waste porcelain powder, albite, black clay, Xikeng mud, ball clay and burnt talc is 27:9:8:24:30:2.

[0031] The fluidity of the slurry is 39s, and the thickness is 1.6.

[0032] The main technical indicators of the product are as follows: the glaze surface is milky white, the whiteness value is 72, the base glaze is well bonded, the Vickers hardness is 602, and the water absorption rate is 0.47%.

Embodiment 3

[0034] The difference between this embodiment and embodiment 1 is:

[0035] The mass ratio of waste porcelain powder, albite, black clay, Xikeng mud, ball clay and burnt talc is 30:8:6:24:30:2.

[0036] The fluidity of the slurry is 34s, the degree of thickening is 1.5, and the firing temperature is 1200°C.

[0037] The main technical indicators of the product are as follows: the glaze surface is milky white, the whiteness value is 80, the base glaze is well bonded, the Vickers hardness is 591, and the water absorption rate is 0.61%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com