Tantalum-tungsten material and preparation method thereof

An ingot casting and pickling technology, applied in the field of metal materials, can solve the problems of large grain size, poor plate homogeneity, uneven grain size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The embodiment of the present invention discloses a method for preparing a tantalum-tungsten material, which includes the following steps:

[0025] 1) The tantalum and tungsten ingot is forged for the first time, and the tantalum and tungsten ingot after the first forging is subjected to the first heat treatment;

[0026] 2) The tantalum and tungsten ingot obtained in step 1) is forged for the second time, and the tantalum and tungsten material after the second forging is subjected to a second heat treatment;

[0027] 3) The tantalum-tungsten ingot obtained in step 2) is rolled, and the rolled tantalum-tungsten ingot is subjected to a third heat treatment to obtain a tantalum-tungsten material.

[0028] According to the present invention, in the process of preparing tantalum-tungsten materials, it is first necessary to provide tantalum-tungsten ingots, which can be obtained by electron beam melting, and the present invention has no special limitation on the preparation ...

Embodiment 1

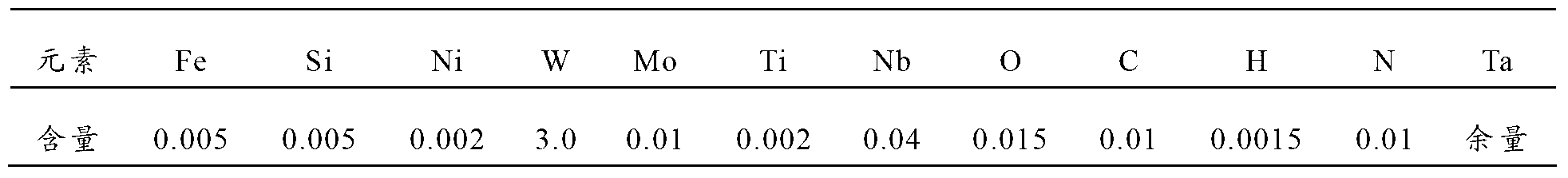

[0041] 1) The tantalum 2.5 tungsten ingot is obtained by electron beam melting. The diameter of the tantalum 2.5 tungsten ingot is 153 mm and the length is 250-260 mm. The composition of the tantalum 2.5 tungsten ingot is shown in Table 1. The elemental composition data table;

[0042] Table 1 Elemental composition data table of tantalum 2.5 tungsten ingot

[0043]

[0044] 2) The tantalum 2.5 tungsten ingot obtained in step 1) was ultrasonically tested, and then the tantalum 2.5 tungsten ingot was heated to 400°C, kept warm for 150 minutes, and then subjected to axial upsetting with an upsetting ratio of 1.6; then radial elongation, Obtain a tantalum 2.5 tungsten rod with a diameter of 100mm and a length of 450mm;

[0045] 3) The tantalum 2.5 tungsten rod obtained in step 2) is divided into 2 sections in the length direction, and one section is taken and the forging defect of the end face is removed;

[0046] 4) Pickling the tantalum 2.5 tungsten rod obtained in step 3):...

Embodiment 2

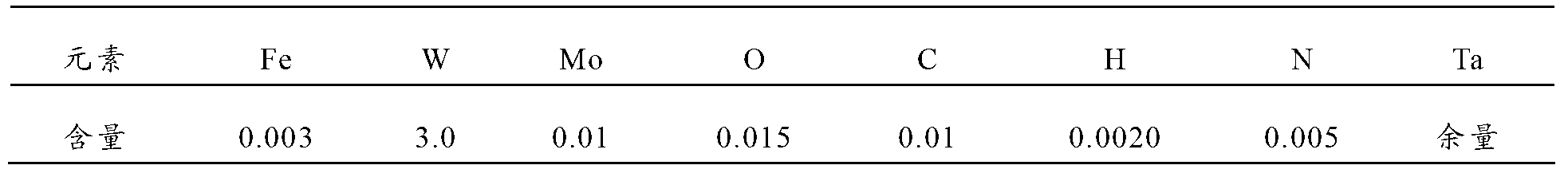

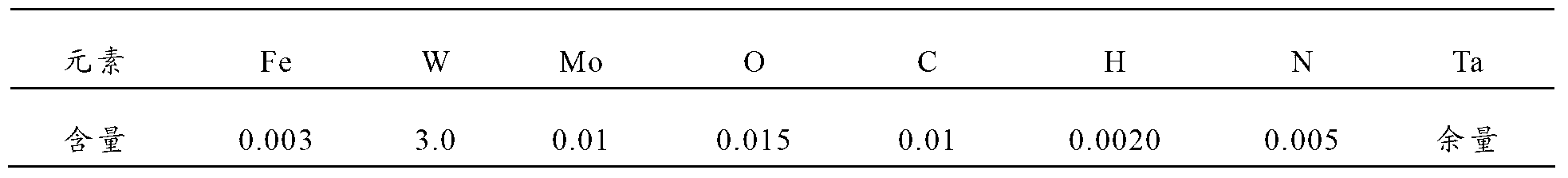

[0057] 1) The tantalum 2.5 tungsten ingot is obtained by electron beam melting. The diameter of the tantalum 2.5 tungsten ingot is 155mm and the length is 242mm. The composition of the tantalum 2.5 tungsten ingot is shown in Table 2. ingredient data sheet;

[0058] Table 2 Elemental composition data table of tantalum 2.5 tungsten ingot

[0059]

[0060] 2) The tantalum 2.5 tungsten ingot obtained in step 1) was ultrasonically inspected, then the tantalum 2.5 tungsten ingot was heated to 500°C, kept warm for 150 minutes, and then subjected to axial upsetting with an upsetting ratio of 2.0; then radial elongation, Obtain a tantalum 2.5 tungsten rod with a diameter of 100mm and a length of 443mm;

[0061] 3) The tantalum 2.5 tungsten rod obtained in step 2) is divided into 2 sections in the length direction, and one section is taken and the forging defect of the end face is removed;

[0062] 4) Pickling the tantalum 2.5 tungsten rod obtained in step 3): the volume ratio of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com