Method for exploiting heavy oil reservoir by strengthening in-situ oil combustion

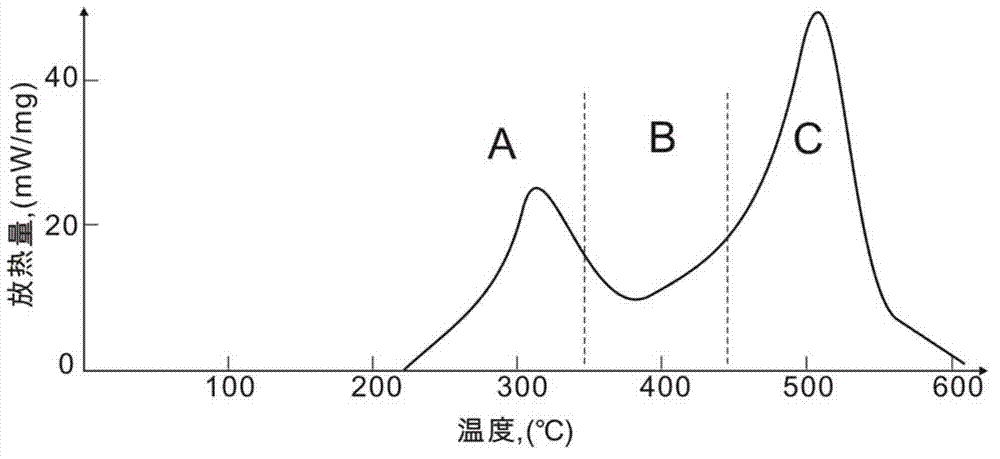

A technology for heavy oil reservoirs and burning oil layers, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., can solve the problems of reduced heat release of crude oil, failure of field tests, and failure of peripheral crude oil to ignite, etc., to achieve safety Combustion oil layer development, realizing the effect of combustion oil layer development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a method for intensifying the exploitation of heavy oil reservoirs by burning oil layers. The underground crude oil viscosity of the heavy oil reservoirs is 10,000 centipoise; the following steps are adopted:

[0027] (1) Five-point vertical well injection-production well pattern is set up in the production area of heavy oil reservoir, and the well spacing between adjacent injection wells and production wells is 150-300m; (2) The oil layer is ignited by chemical ignition; ( 3) Continuously inject air from the vertical well injection well into the reservoir to maintain combustion, and the air injection speed is 10000Nm 3 / day; (4) The production well is opened, and continuous oil production is adopted by the self-spraying method, and the maximum liquid drainage speed of the production well is 50Nm 3 / day, the maximum exhaust velocity is 10000Nm 3 / day; (5) Air injection volume of injection well every 100000Nm 3 , instead inject 1m of hydrogen...

Embodiment 2

[0030] This embodiment provides a method for intensifying the exploitation of heavy oil reservoirs by burning oil layers. The underground crude oil viscosity of the heavy oil reservoirs is 500,000 centipoise; the following steps are adopted:

[0031] (1) In the production area of heavy oil reservoirs, an inverted seven-point vertical well injection-production well pattern is set up, and the well spacing between adjacent injection wells and production wells is 220m; (2) The oil layer is ignited by electric ignition; (3 ) Continuously inject air from the vertical well injection well into the reservoir to maintain combustion, and the injected air speed is 12000Nm 3 / day; (4) The production well is opened, and the electric submersible pump with high temperature resistance above 350℃ is used for continuous oil production, and the maximum liquid drainage speed of the production well is 80Nm 3 / day, the maximum exhaust velocity is 12000Nm 3 / day; (5) Air injection volume of inject...

Embodiment 3

[0034] This embodiment provides a method for intensifying the exploitation of heavy oil reservoirs by burning oil layers. The underground crude oil viscosity of the heavy oil reservoirs is 1,000,000 centipoise; the following steps are used:

[0035](1) In the production area of heavy oil reservoirs, an inverted nine-point vertical well injection-production well pattern is set up, and the well spacing between adjacent injection wells and production wells is 300m; (2) The oil layer is ignited by electric ignition; (3 ) Continuously inject air from the vertical well injection well into the oil reservoir to maintain combustion, and the air injection speed is 15000Nm 3 / day; (4) The production well is opened, and the artificial lift method of the screw pump with a high temperature resistance above 350°C is used for continuous oil production, and the maximum liquid drainage speed of the production well is 100Nm 3 / day, the maximum exhaust velocity is 15000Nm 3 / day; (5) Air injec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com