Fatigue-resistant narrow V-belt and production method thereof

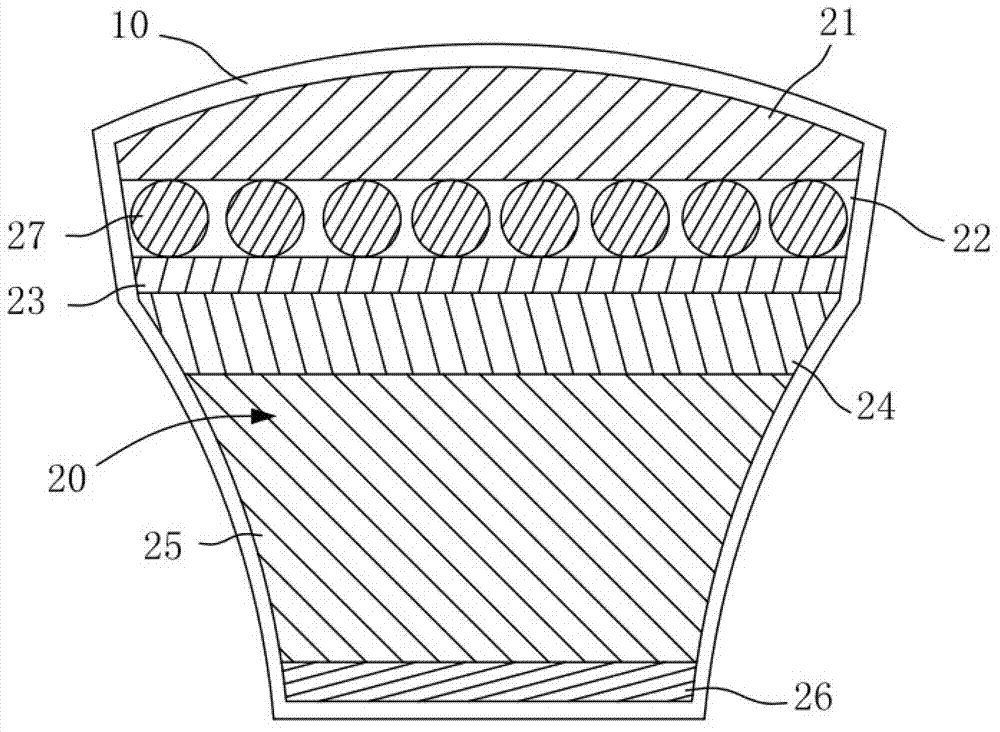

A fatigue-resistant, formula-based technology, applied to V-belts, mechanical equipment, belts/chains/gears, etc., can solve the problems of insufficient longitudinal flexibility and poor fatigue resistance of narrow V-belts, and achieve enhanced lateral rigidity and flex resistance Aging properties, increased longitudinal flexibility, and reduced belt internal stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

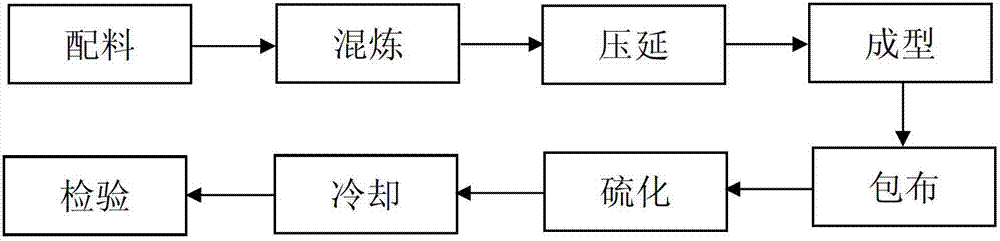

Method used

Image

Examples

Embodiment 1

[0034] 1 kneading

[0035] (1) Fiber reinforced layer

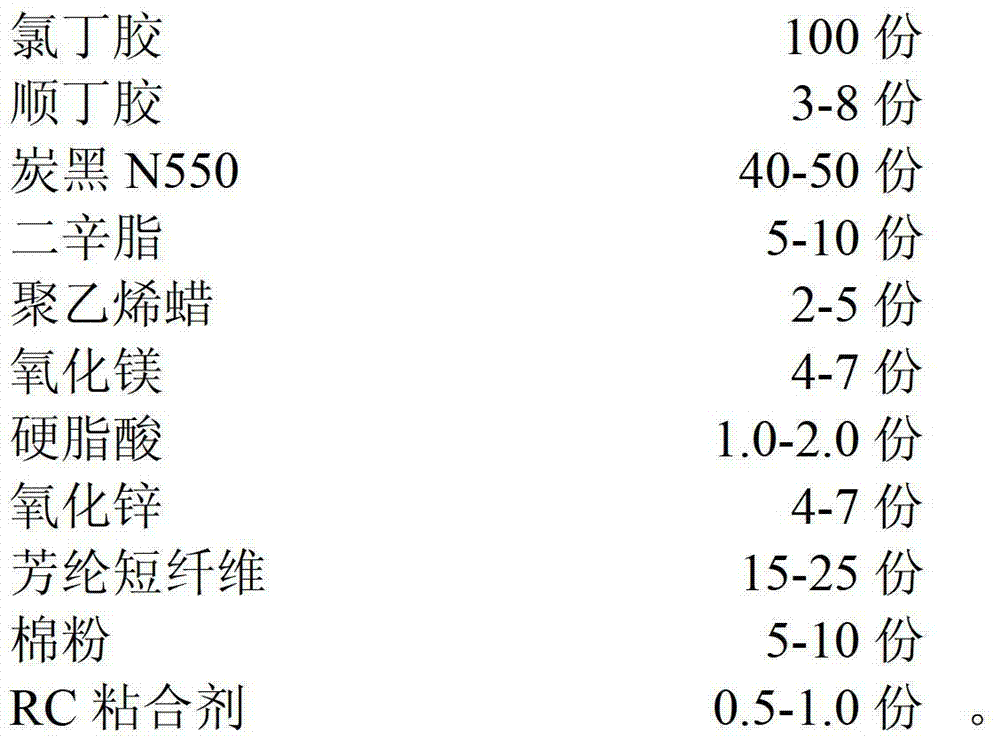

[0036] One-stage mixing: 100 parts of neoprene and 3 parts of butadiene rubber form the base rubber. First, add 15 parts of cotton powder and 0.5 parts of RC adhesive to the base rubber. After the cotton powder and RC adhesive are dispersed evenly, Add 40 parts of carbon black N550 and 5 parts of dioctyl ester; the feeding temperature is controlled at 70±5°C, and the discharge temperature is controlled at 115±5°C;

[0037] Two-stage mixing: add 4 parts of magnesium oxide and 4 parts of zinc oxide, and control the feeding temperature at 65±5°C; when the temperature rises to about 85°C, add 1 part of stearic acid and 2 parts of polyethylene wax; discharge temperature Controlled at 100±5°C.

[0038] (2) Flexible and toughened layer

[0039] One-stage mixing: 100 parts of neoprene and 3 parts of butadiene rubber form the base rubber. First, add 5 parts of cotton powder, 15 parts of aramid staple fiber and 0.5 part of RC ad...

Embodiment 2

[0057] 1 kneading

[0058] (1) Fiber reinforced layer

[0059] One-stage mixing: 100 parts of neoprene and 8 parts of butadiene rubber form the base rubber. First add 25 parts of cotton powder and 1 part of RC adhesive to the base rubber. After the cotton powder and RC adhesive are dispersed evenly, Add 50 parts of carbon black N550 and 10 parts of dioctyl ester; the feeding temperature is controlled at 70±5°C, and the discharge temperature is controlled at 115±5°C;

[0060] Two-stage mixing: add 7 parts of magnesium oxide and 7 parts of zinc oxide, and control the feeding temperature at 65±5°C; when the temperature rises to about 85°C, add 2 parts of stearic acid and 5 parts of polyethylene wax; discharge temperature Controlled at 100±5°C.

[0061] (2) Flexible and toughened layer

[0062] One-stage mixing: 100 parts of neoprene and 8 parts of butadiene rubber form the base rubber, firstly add 10 parts of cotton powder, 25 parts of aramid staple fiber and 1 part of RC adhe...

Embodiment 3

[0071] 1 kneading

[0072] (1) Fiber reinforced layer

[0073] One-stage mixing: 100 parts of neoprene and 5 parts of butadiene rubber form the base rubber. First add 20 parts of cotton powder and 0.8 parts of RC adhesive to the base rubber. After the cotton powder and RC adhesive are dispersed evenly, Add 45 parts of carbon black N550 and 8 parts of dioctyl ester; the feeding temperature is controlled at 70±5°C, and the discharge temperature is controlled at 115±5°C;

[0074] Two-stage mixing: add 5.5 parts of magnesium oxide and 5.5 parts of zinc oxide, and control the feeding temperature at 65±5°C; when the temperature rises to about 85°C, add 1.5 parts of stearic acid and 3.5 parts of polyethylene wax; discharge temperature Controlled at 100±5°C.

[0075] (2) Flexible and toughened layer

[0076] One-stage mixing: 100 parts of neoprene and 5 parts of butadiene rubber form the base rubber. First add 8 parts of cotton powder, 20 parts of aramid staple fiber and 0.8 part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com