Device and method for evaluating oil paper insulation aging and predicting service life of transformer

A technology of aging assessment and transformer oil, which is applied in measuring devices, testing of machine/structural components, instruments, etc., and can solve problems such as failure to support insulation, failure to replace insulation paper, and decline in mechanical strength of insulation paper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] A device for aging assessment and life prediction of transformer oil-paper insulation, the device is:

[0053] (1) Long-term aging device

[0054] It is the DHG-9070A type electric heating constant temperature blast drying oven of Shanghai Hecheng Instrument Co., Ltd., such as figure 1 as shown, figure 1 It is a schematic diagram of an electric constant temperature blast drying oven; this equipment can realize long-term heating with controllable temperature and humidity between 0-300 degrees, and can set temperature control curves at different times; the sealing performance during heating is determined by the processing of test vessels get;

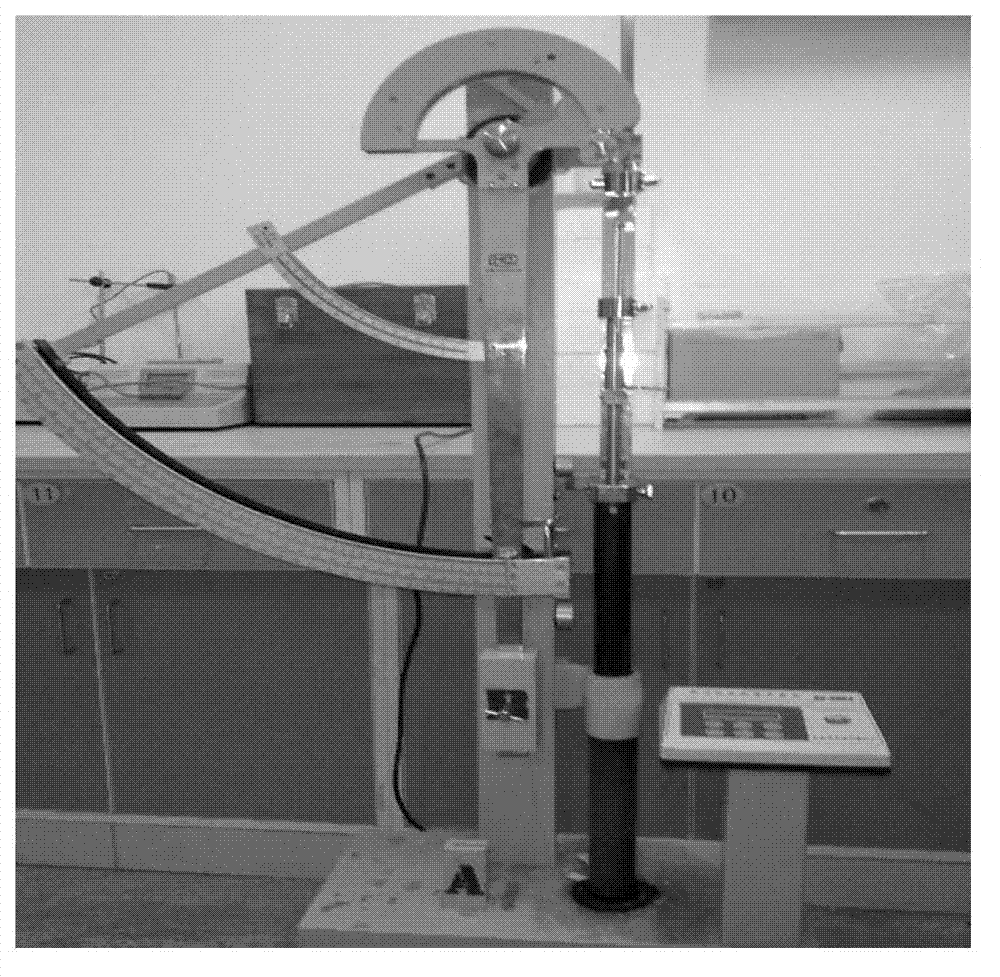

[0055] (2) Degree of polymerization testing device

[0056] The device adopts the most commonly used method for measuring the degree of polymerization, which is to measure the kinematic viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Tear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com