Large-scale power rectifier cabinet silicon controlled rectifier continuity detection device

A technology of continuity detection and rectifier cabinet, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve hidden dangers, insufficient detection of power components, and high commutation voltage, so as to eliminate hidden dangers and shorten the time of working with diseases. Maintenance time, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

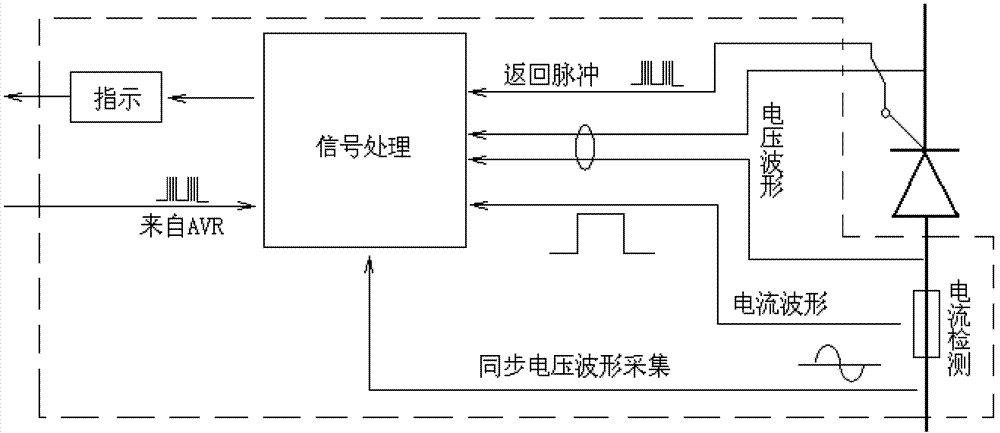

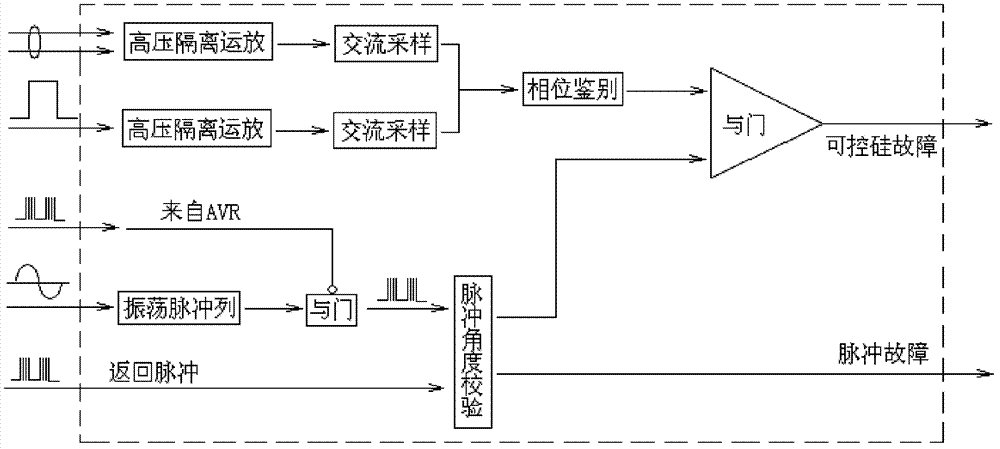

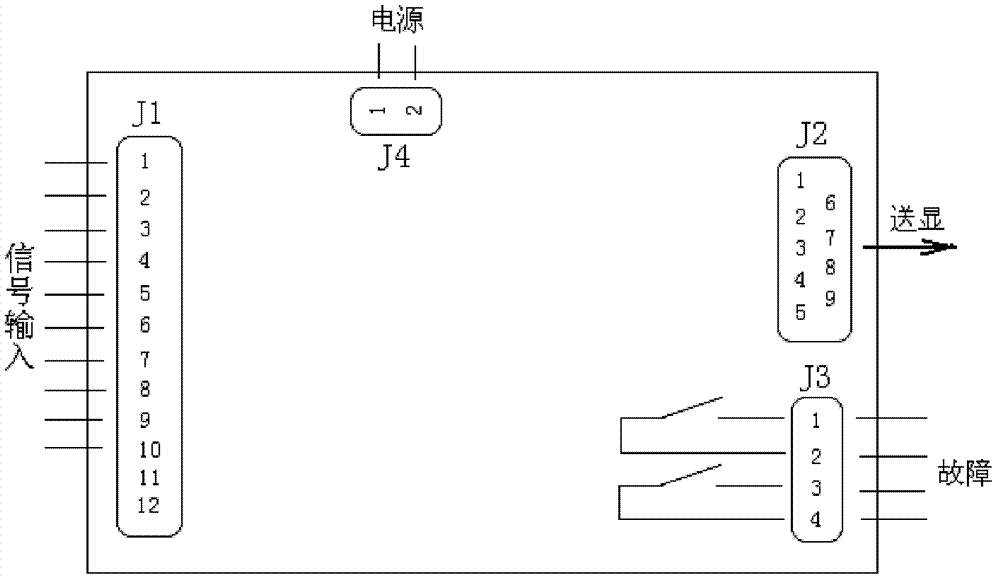

[0015] The thyristor conduction detection device is divided into three parts: signal acquisition, signal processing, and display. Signal acquisition includes thyristor bridge arm current acquisition, thyristor tube voltage drop waveform acquisition, thyristor actual trigger pulse acquisition, AVR actual trigger angle acquisition, anode synchronous voltage acquisition; the signal processing part will collect various signals Comprehensive processing to identify the fault type of the thyristor and accurately locate it; the sending display part displays the phase difference of the faulty thyristor online, and outputs the contact signal to the monitoring system. See the attached schematic diagram of the electrical principle figure 1 , the schematic diagram of the signal processing principle is attached figure 2 , the application wiring diagram see image 3 .

[0016] See figure 1 : The electrical quantity when the thyristor is working mainly includes branch current, tube volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com