Optical system for homogenizing semiconductor laser beam of area array

An optical system and laser beam technology, applied in the field of optical systems, can solve the problems of low energy utilization rate, poor uniformity, and difficult to integrate and assemble, so as to reduce process difficulty and production cost, improve energy utilization rate, and increase the number of divisions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

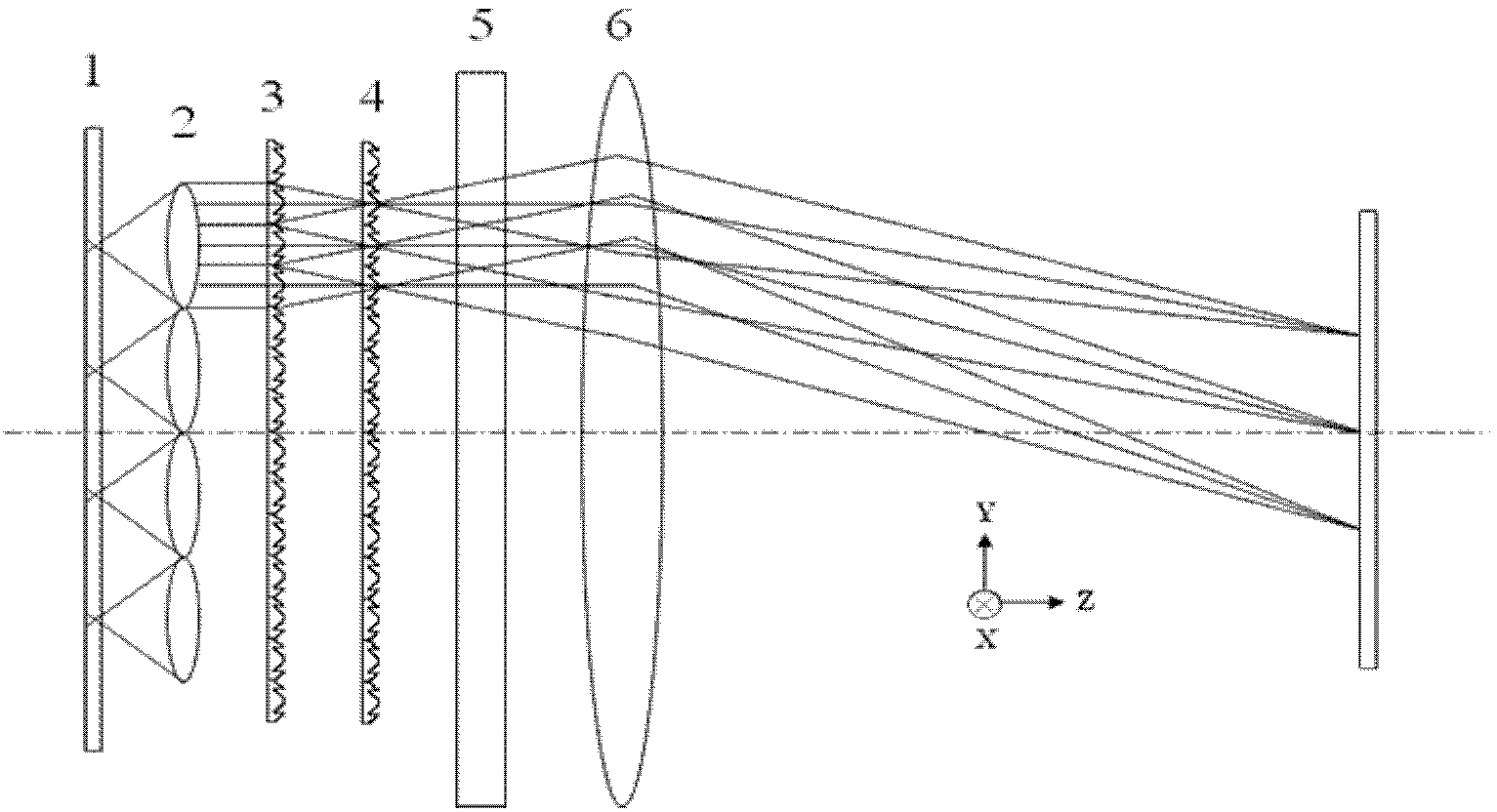

[0036]Using the first microlens array 3 and the second microlens array 4 as the laser homogenizer, the parameters that need to be determined are the parameters of the cylindrical Fresnel diffraction microlens 7 , the slow axis field lens 5 , and the fast axis field lens 6 . The schematic diagram of the area array semiconductor laser beam homogenization system composed of the first microlens array 3 and the second microlens array 4 is as follows: Figure 1a and Figure 1b ,in:

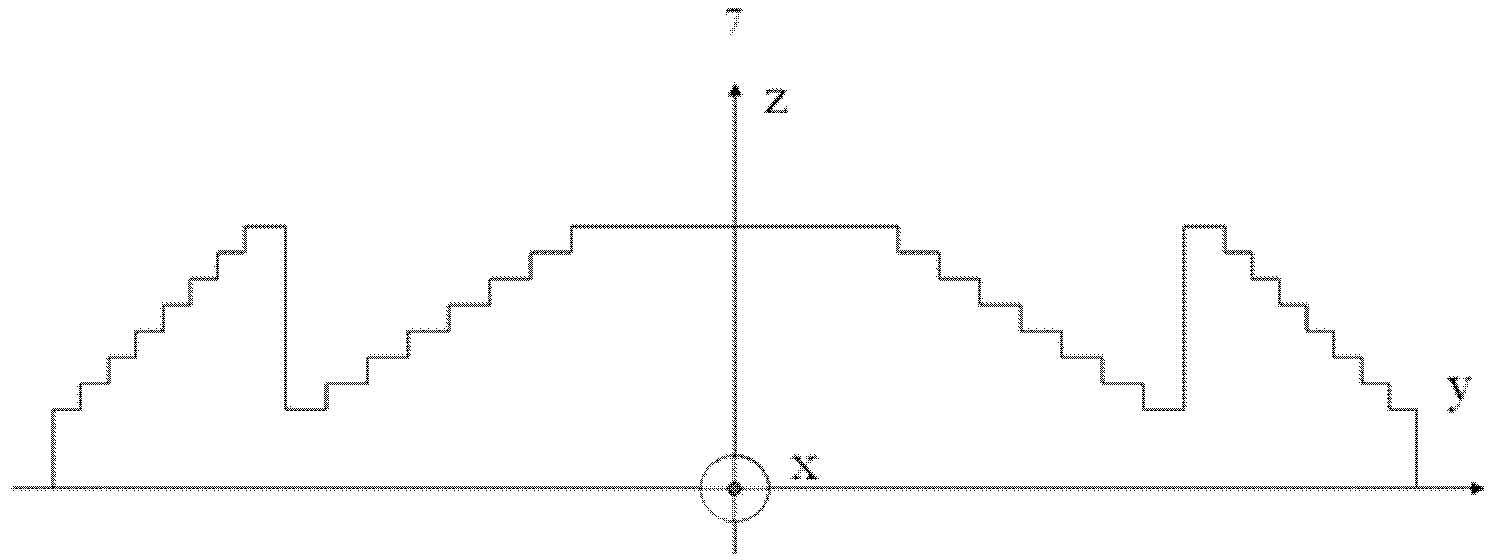

[0037] Parameters of a cylindrical Fresnel diffractive microlens 7: Aperture D FMLA =0.125mm, focal length f FMLA =1.25mm, the number of phase steps N=8;

[0038] Parameters of slow axis field lens 5: focal length f FS =375mm, caliber D FS =127mm, length L FS =160mm;

[0039] Parameters of the fast-axis field lens 6: focal length f FF =300mm, caliber D FF =160mm, length L FF =127mm;

[0040] All materials of the system are silicon dioxide (SILICA).

Embodiment 2

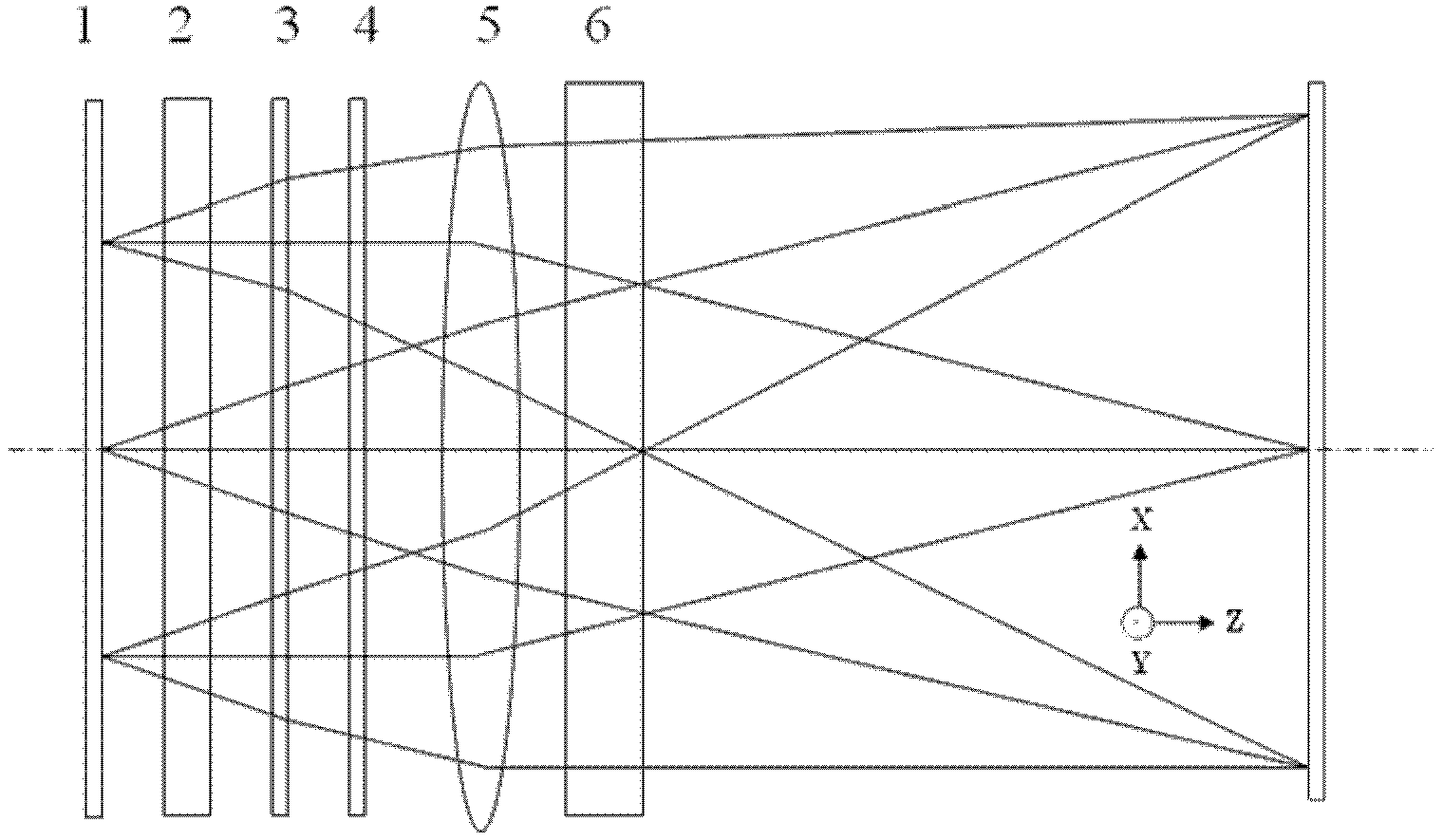

[0042] Using the first microlens array 3 or the second microlens array 4 as a laser homogenizer, the parameters that need to be determined are the parameters of the cylindrical Fresnel diffraction microlens 7 , the slow axis field lens 5 , and the fast axis field lens 6 . The schematic diagram of the area array semiconductor laser beam homogenization system composed of the first microlens array 3 or the second microlens array 4 is as follows: Figure 6a and Figure 6b ,in:

[0043] Parameters of a cylindrical Fresnel diffractive microlens 7: Aperture D FMLA =0.125mm, focal length f FMLA =1.25mm, the number of phase steps N=8;

[0044] Parameters of slow axis field lens 5: focal length f FS =375mm, caliber D FS =127mm, length L FS =160mm;

[0045] Parameters of the fast-axis field lens 6: focal length f FF =300mm, caliber D FF =160mm, length L FF =127mm;

[0046] All materials of the system are silicon dioxide (SILICA).

[0047] In order to verify the feasibility of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com