Isolation chamber for isolating laser produced plasma extreme ultraviolet light source fragments

A technology of laser plasma and extreme ultraviolet light source, applied in the field of isolation cavity, can solve the problems of large airflow vortex and other problems, and achieve the effects of isolating pollution, improving lifespan, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below can be combined with each other as long as they do not constitute a conflict with each other.

[0018] Based on some deficiencies in the isolation of laser plasma debris in some existing technologies, the present invention provides an isolation cavity, which is especially suitable for isolating laser liquid tin plasma debris.

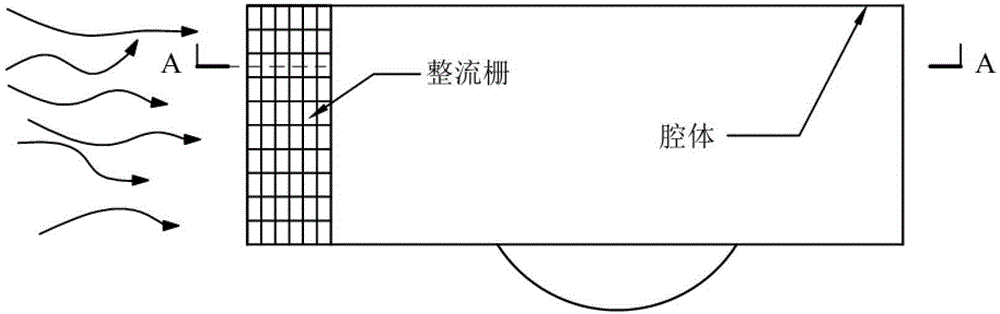

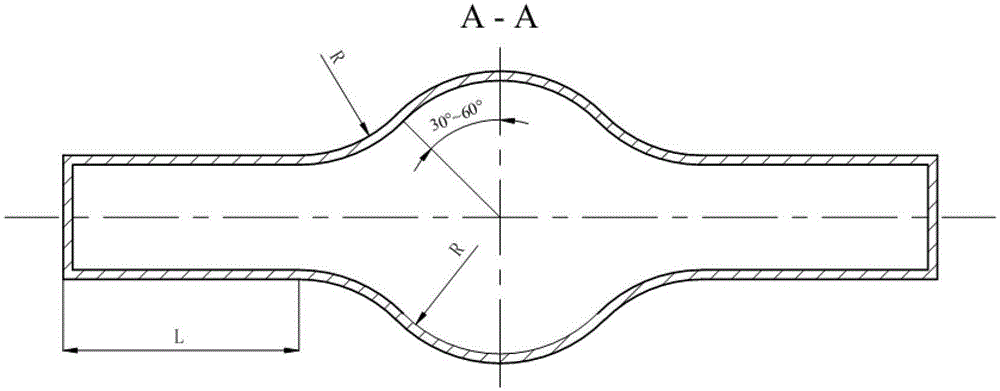

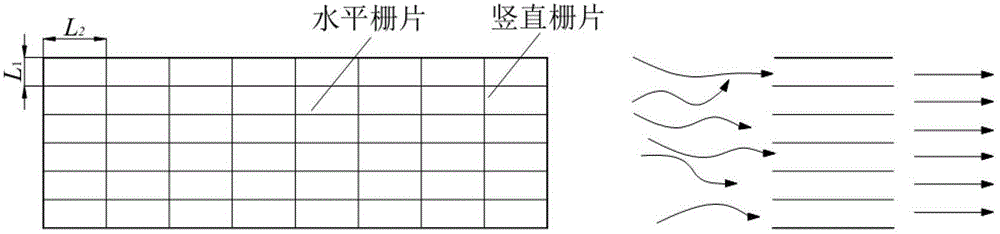

[0019] Figure 1a and Figure 1b A schematic diagram of the shape and structure of the isolation cavity provided by the present invention is shown. in, Figure 1a The connection position between the rectifier grid and the cavity in the iso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com