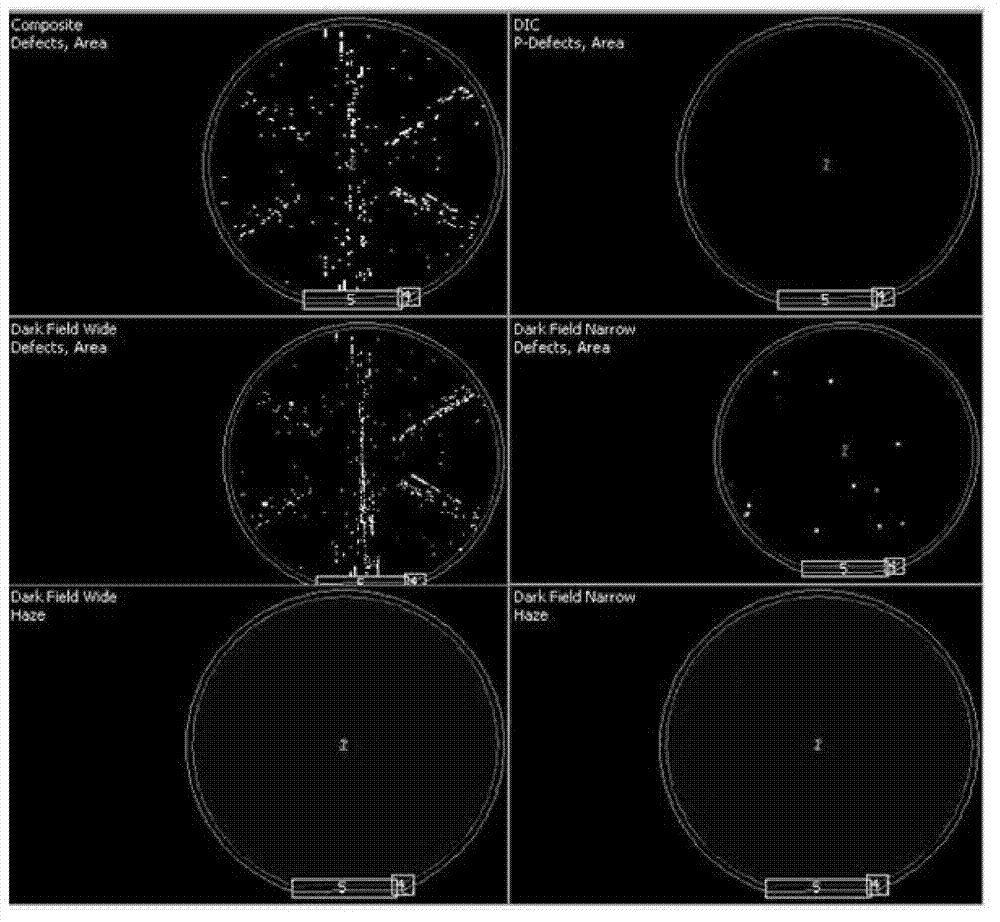

Preparation method of P-layer silicon epitaxial wafer on P++ substrate

A technology of silicon epitaxial wafers and substrates, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increased leakage current, drastic changes, lattice mismatch, etc., to increase control costs, increase The uniformity of resistivity and the effect of improving the formation of misfit dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Use P+ / Boron single-sided polishing sheet, resistivity 0.004~0.0075Ω·cm, thickness 525±15μm, silicon wafer diameter 125±0.2mm, back LTO back seal, edge removal width ≤1mm;

[0042] (2) HCl in-situ polishing is performed at 1100°C, the HCl flow rate is 5slm / 10min, and the removal amount on the surface of the silicon wafer is 0.3 microns;

[0043] (3) Purge: use H 2 Purge the reaction chamber for 8 minutes, and discharge the impurities generated after the surface of the silicon wafer is polished out of the chamber, H 2 The flow rate is 140slm / 10min;

[0044] (4) Double-layer epitaxial growth: using high-purity SiHCl 3 Deposition and growth of resistivity graded layer, growth rate 0.40μm / min, growth temperature 1070°C, resistivity gradient layer thickness 1.4μm; then growth resistivity doped layer, growth temperature 1070°C, growth rate controlled at 0.8μm / min.

Embodiment 2

[0046] (1) Use P+ / Boron single-sided polishing sheet, resistivity 0.004~0.0075Ω·cm, thickness 525±15μm, silicon wafer diameter 125±0.2mm, back LTO back seal, edge removal width ≤1mm;

[0047] (2) HCl in-situ polishing is performed at 1130°C, the HCl flow rate is 5slm / 10min, and the removal amount on the surface of the silicon wafer is 0.4 microns;

[0048] (3) Purge: use H 2 Purge the reaction chamber for 10 minutes, and discharge the impurities generated after the surface of the silicon wafer is polished out of the chamber, H 2 The flow rate is 130slm / 10min;

[0049] (4) Double-layer epitaxial growth: using high-purity SiHCl3 Deposition and growth of the resistivity graded layer, the growth rate is 0.38μm / min, the growth temperature is 1080°C, the thickness of the resistivity gradient layer is 1.5μm; then the resistivity doped layer is grown, the growth temperature is 1100°C, and the growth rate is controlled at 1.0μm / min.

Embodiment 3

[0051] (1) Use P+ / Boron single-sided polished sheet, resistivity 0.004~0.0075Ω·cm, thickness 525±15μm, silicon wafer diameter 125±0.2mm, back LTO back seal, edge removal width ≤1mm;

[0052] (2) HCl in-situ polishing is performed at 1120°C, the HCl flow rate is 5slm / 10min, and the removal amount on the surface of the silicon wafer is 0.3 microns;

[0053] (3) Purge: use H 2 Purge the reaction chamber for 11 minutes, and discharge the impurities generated after the surface of the silicon wafer is polished out of the chamber, H 2 The flow rate is 170slm / 10min;

[0054] (4) Double-layer epitaxial growth: using high-purity SiHCl 3 Deposition and growth of the resistivity gradient layer, the growth rate is 0.42μm / min, the growth temperature is 1100°C, the thickness of the resistivity gradient layer is 1.3μm; then the resistivity doped layer is grown, the growth temperature is 1080°C, and the growth rate is controlled at 0.9μm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com