Preparation method and application of nitrogen and iron modified carbon material

A carbon material and carbon powder technology, which is applied in the preparation of the carbon material, the application in the preparation of fuel cells, and the field of carbon materials modified with nitrogen and iron, can solve the shortage of resources, restrict the industrialization process of low-temperature fuel cells, and the expensive price of precious metals and other problems, to achieve the effect of aerobic reduction performance, improvement of oxygen reduction catalytic activity, and improvement of catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

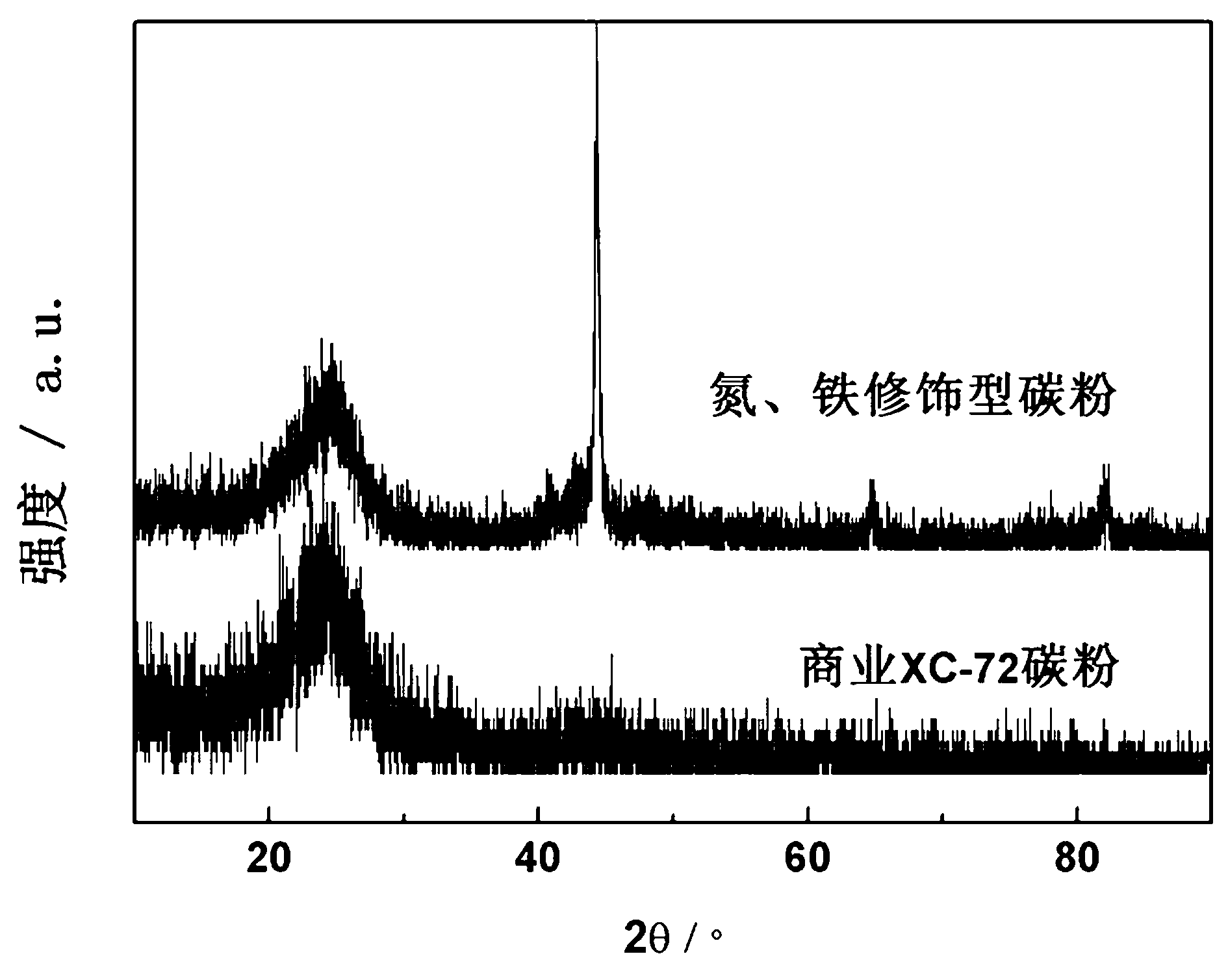

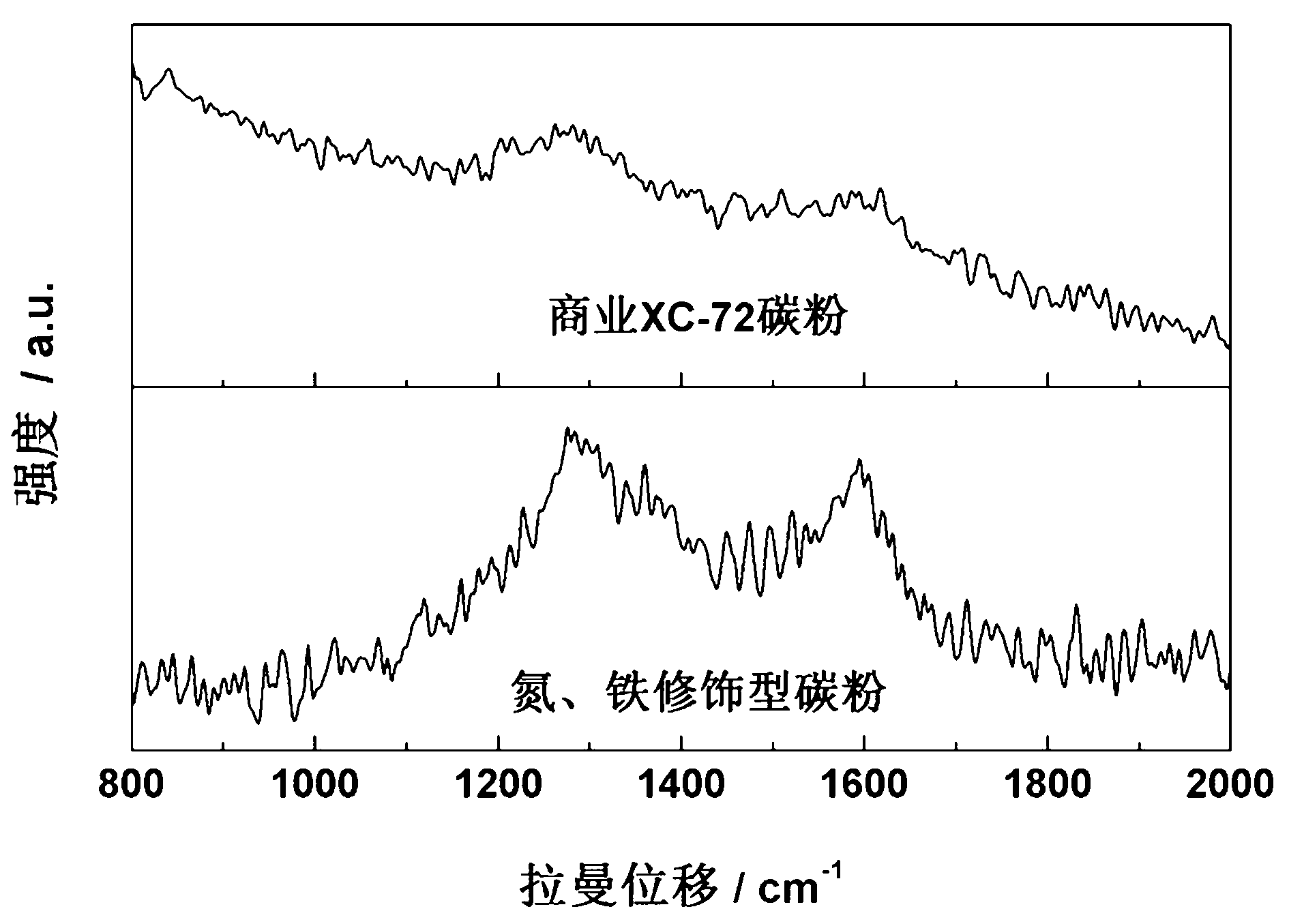

[0027] Add 150 ml of ultra-pure water to a 400 ml beaker, heat to boiling, add 4 g of melamine, stir to fully dissolve; then add 4 g of commercial XC-72 carbon powder, continue to stir to mix evenly, and then ultrasonically disperse for 10 minutes; Then slowly drop 10 mL of FeCl with a concentration of 2 mol / L 3 Aqueous solution, stirred at room temperature for 24 h, suction filtered, washed, dried in an oven at 60 °C for 10 h, the resulting product was placed in a tube furnace, and heat-treated at 600 °C for 2 h under the protection of nitrogen to obtain nitrogen and iron modified carbon powder .

[0028] Through the oxygen reduction test, it is found that the onset potential and half-wave potential of the oxygen reduction reaction are positively shifted by 89 mV and 42 mV respectively compared with the traditional commercial XC-72 carbon powder when the decorated carbon powder material modified with nitrogen and iron is used as the cathode electrode of the fuel cell .

Embodiment 2

[0030] Add 150 ml of ultrapure water into a 400 ml beaker, heat to boiling, add 4 g of melamine, stir to dissolve to fully dissolve; then add 8 g of commercial XC-72 carbon powder, continue to stir and mix evenly, and then ultrasonically disperse for 10 minutes; then Slowly add 10 mL of FeCl with a concentration of 3 mol / L dropwise 3 Aqueous solution, stirred and reacted at room temperature for 24 h, suction filtered, washed, dried in an oven at 60 °C for 10 h, the resulting product was placed in a tube furnace, and heat-treated at 800 °C for 2 h under the protection of nitrogen to obtain nitrogen and iron modified carbon powder .

[0031] Through the oxygen reduction test, it is found that the onset potential and half-wave potential of the oxygen reduction reaction are positively shifted by 121mV and 72mV respectively compared with the traditional commercial XC-72 carbon powder when the decorated carbon powder material modified with nitrogen and iron is used as the cathode el...

Embodiment 3

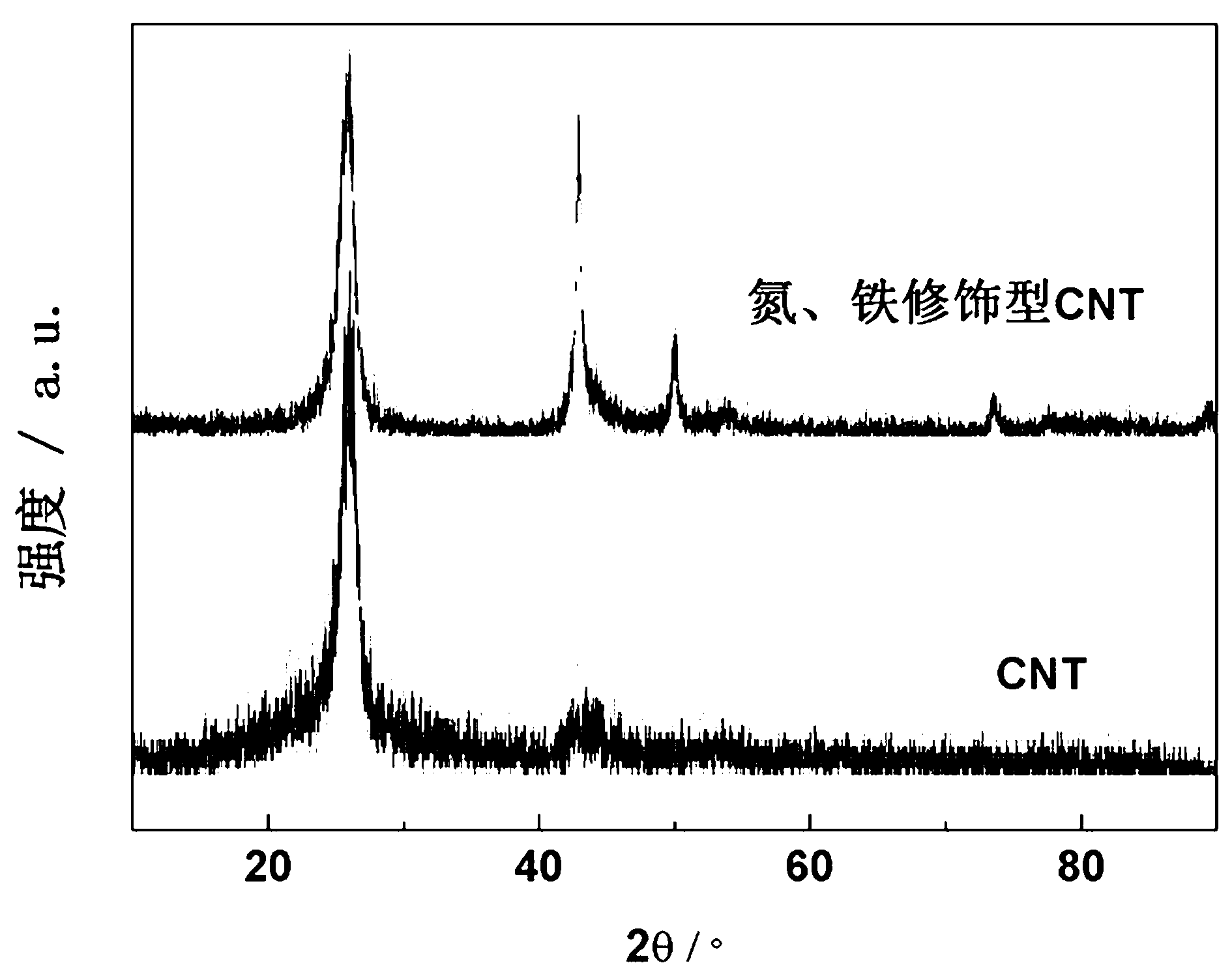

[0033] Add 150 ml of ultrapure water into a 400 ml beaker, heat to boiling, add 4 g of melamine and stir to fully dissolve; then add 4 g of carbon nanotubes, continue to stir and mix evenly, and then ultrasonically disperse for 10 minutes; then slowly add 10 mL of concentration 2 mol / L FeCl 3 The aqueous solution was stirred at room temperature for 24 hours, suction filtered, washed, and dried at 60 °C for 10 h. The obtained product was placed in a tube furnace and heat-treated at 600 °C for 2 h under the protection of nitrogen to obtain nitrogen and iron-modified carbon nanotubes.

[0034] Through the oxygen reduction test, it is found that the onset potential and half-wave potential of the oxygen reduction reaction are positively shifted by 106 mV and 57 mV respectively compared with the carbon nanotubes when the decorated carbon powder material modified with nitrogen and iron is used as the cathode electrode of the fuel cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com