Wear-resisting cigarette packaging thin film and production method thereof

A technology for packaging film and cigarettes, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc. It can solve the problems of film scratches, irregular shapes, wide dispersion of anti-blocking agent particles, etc., and meet the requirements of heat sealing Resistance and wear resistance, meet the requirements of heat sealing performance, the effect of good heat sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

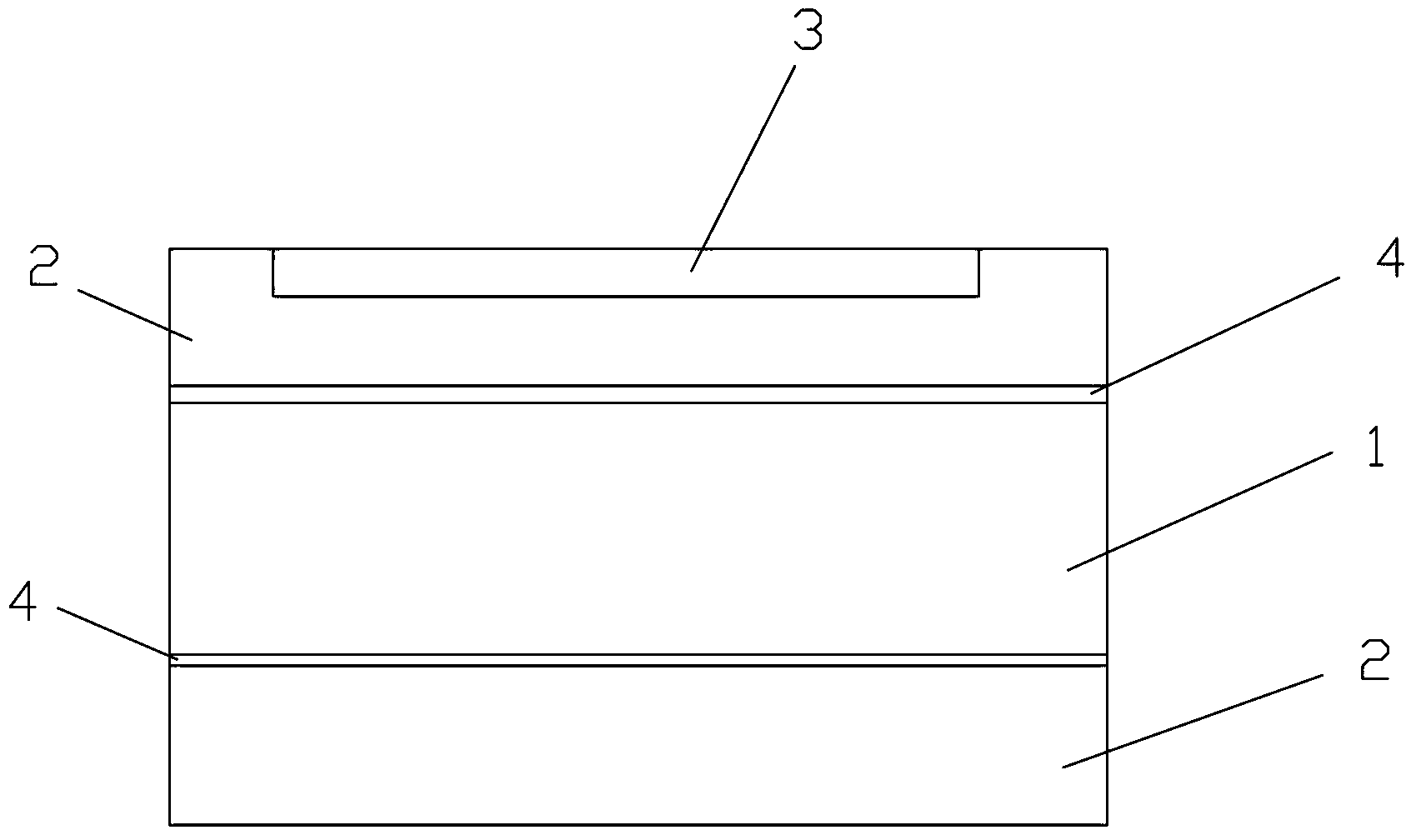

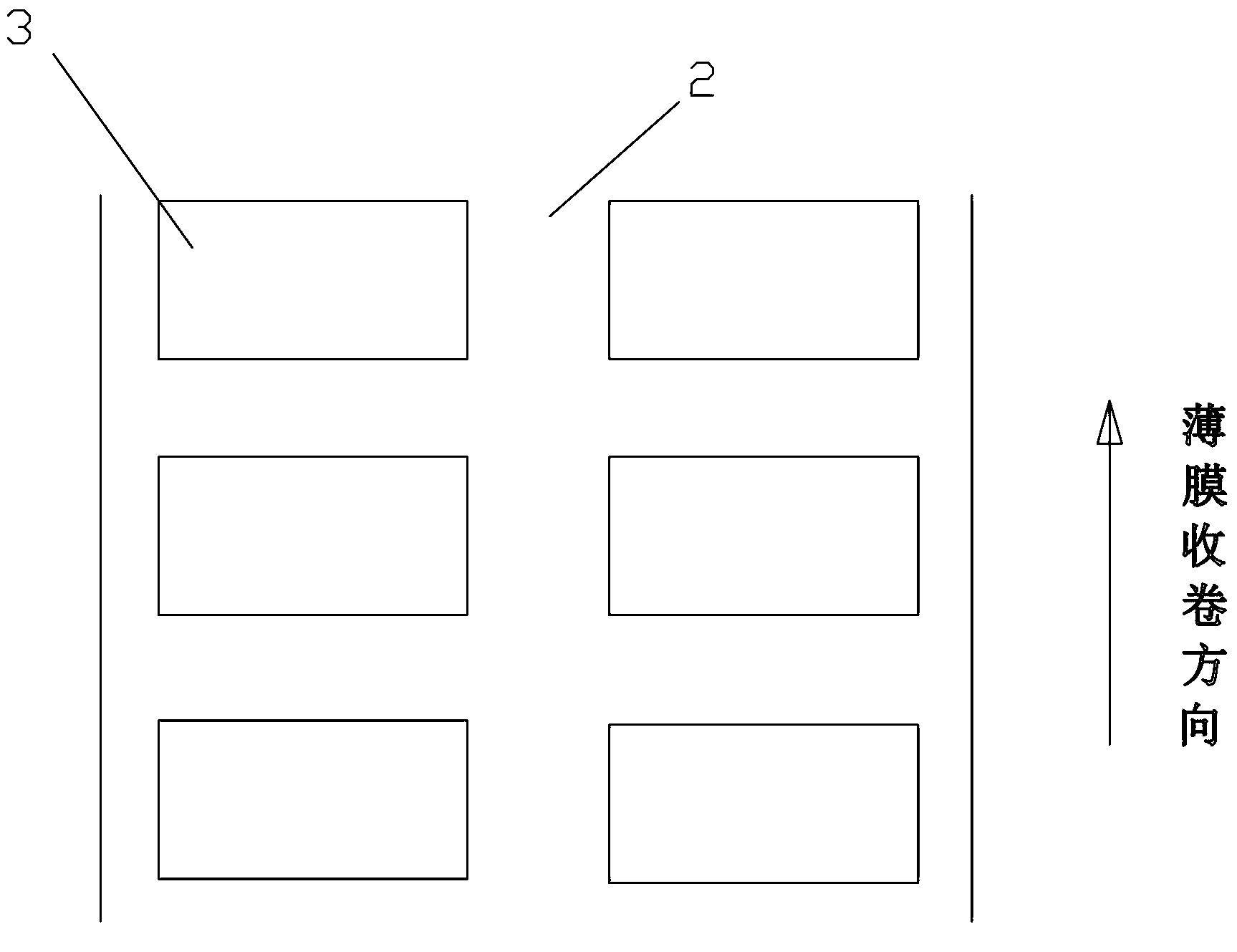

[0034] refer to figure 1 , 2 , a kind of wear-resisting cigarette packaging film of the present invention comprises BOPP film layer 1, and polyacrylate layer 2 is all arranged on the upper and lower surfaces of BOPP film layer 1, and the polyacrylate layer 2 on the upper surface of BOPP film layer 1 is provided with several The pit is filled with a transparent UV curable coating 3, and the BOPP film layer 1 and the polyacrylate layer 2 are bonded by transparent glue.

[0035] The film substrate used in the present invention is a BOPP film produced from homopolymerized PP with a single-layer structure, and its layer thickness is 17-19 μm. Its technological process ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com