Novel roller-compacted concrete for dams and preparation method thereof

A new type of roller compacted concrete technology, applied in the field of new type of roller compacted concrete and its preparation, can solve the problems of high fineness modulus, low reserves, and difficulty in guaranteeing admixture quality, and achieve high compressive strength and flexural strength, Small amount of civil works and installation works, significant energy saving and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

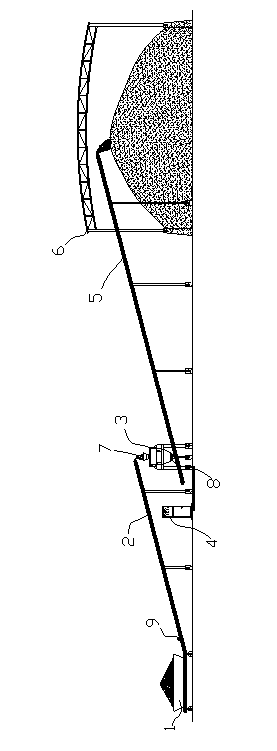

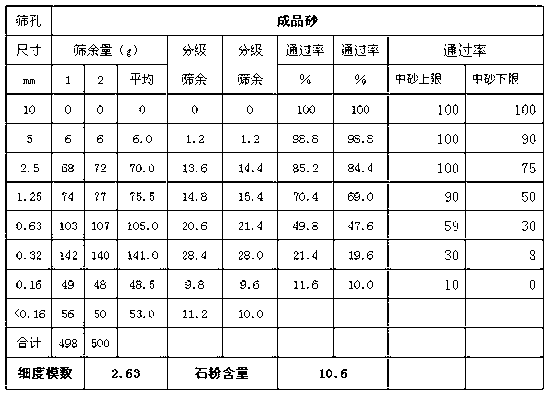

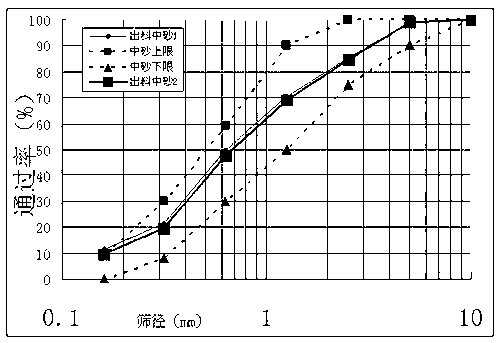

[0048] The present invention is a novel roller compacted concrete for dams, which comprises the following components by weight: 60 parts of water, 55 parts of cement, 70 parts of fly ash, 500 parts of river sand, 1400 parts of coarse aggregate, retarded 0.876 parts of superplasticizer and 0.02 parts of air-entraining agent. The coarse aggregate comprises the following components by weight and specific gravity: 420 parts of small stones, 560 parts of medium stones, and 420 parts of large stones. The fineness modulus of the river sand is 2.6±0.2; the river sand is granite, and its compressive strength is 100-300 MPa. The retarding high-efficiency water reducer is a naphthalene-based high-efficiency water reducer. The present invention uses ZB-1Rcc15, which is a brown powder mainly composed of β-naphthalenesulfonate formaldehyde condensate and selected high-purity organic components. Dissolved in water. The air-entraining agent is rosin resin air-entraining agent. The main comp...

Embodiment 2

[0059] The preparation method and crushing device used in this embodiment are the same as those in Embodiment 1, the only difference is that a novel roller compacted concrete for dams of the present invention includes the following components by weight: water 95 51 parts of cement, 95 parts of fly ash, 650 parts of river sand, 1473 parts of coarse aggregate, 1.46 parts of retarding superplasticizer and 0.0292 parts of air-entraining agent. The coarse aggregate comprises the following components by weight and specific gravity: 442 parts of small stones, 589 parts of medium stones, and 442 parts of large stones. The fineness modulus of the river sand is 2.6±0.2; the river sand is granite, and its compressive strength is 100-300 MPa. The retarding high-efficiency water reducer is a naphthalene-based high-efficiency water reducer. The present invention uses ZB-1Rcc15, which is a brown powder mainly composed of β-naphthalenesulfonate formaldehyde condensate and selected high-purity...

Embodiment 3

[0061] The preparation method and the crushing device used in this embodiment are the same as those in Embodiments 1 and 2, except that a novel roller compacted concrete for dams of the present invention includes the following components by weight: 110 parts of water, 59 parts of cement, 120 parts of fly ash, 700 parts of river sand, 1500 parts of coarse aggregate, 1.1 parts of retarding superplasticizer and 0.04 parts of air-entraining agent. The coarse aggregate includes the following components by weight and specific gravity: 450 parts of small stones, 600 parts of medium stones, and 450 parts of large stones. The fineness modulus of the river sand is 2.6±0.2; the river sand is granite, and its compressive strength is 100-300 MPa. The retarding high-efficiency water reducer is a naphthalene-based high-efficiency water reducer. The present invention uses ZB-1Rcc15, which is a brown powder mainly composed of β-naphthalenesulfonate formaldehyde condensate and selected high-pur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Maximum particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com