Ferrite for anechoic chamber and preparation method and applications thereof

An anechoic chamber and ferrite technology, which is applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of high cost and achieve the effect of high precision and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A ferrite preparation method for an anechoic chamber, the steps of which are:

[0042] (1) Configure the component Fe of each mass percentage 2 O 3 :64.6%, MnO:19.6%, ZnO:13.6%, CuO:1.5%, CoO:0.6%, SiO 2 :0.06%, CaO:0.02%, Cr 2 O 3:0.01%, Cl:0.01%;

[0043] (2) Mix the above components for powder making. The powder making adopts wet sand milling process, so that the raw materials are mixed more uniformly and then pre-fired. (3) After wet mixing, pre-fire at a temperature of 750 ° C. Burning, the atmosphere is atmospheric, and the pre-burning is kept for 5 hours; (4) After pre-burning, use a second ball mill to make a fine powder, the particle size is 1-3um, and the grinding and crushing time is 4 hours; (5) Combined with spray granulation Granulation, the particle range is 20 mesh / cm~65 mesh / cm, and the bulk density is 1.2g / cm 3 ~1.25g / cm 3 , the sliding angle is 35°; (6) A blank with a width of 100mm, a length of 100mm and a thickness of 5.2mm is formed by a mol...

Embodiment 2

[0057] Its composition and manufacturing process of the product of embodiment 2 are the same as embodiment 1, except that the grinding and pulverizing time is 12 hours.

[0058] 1. Use a laser particle size analyzer (MS2000) to analyze the particle size distribution of the powder. Its 50% particle size distribution of embodiment 2 product is 0.821 (micron), and 90% particle size distribution is 1.226 (micron), and the average grain diameter after firing is 16.1 (micron).

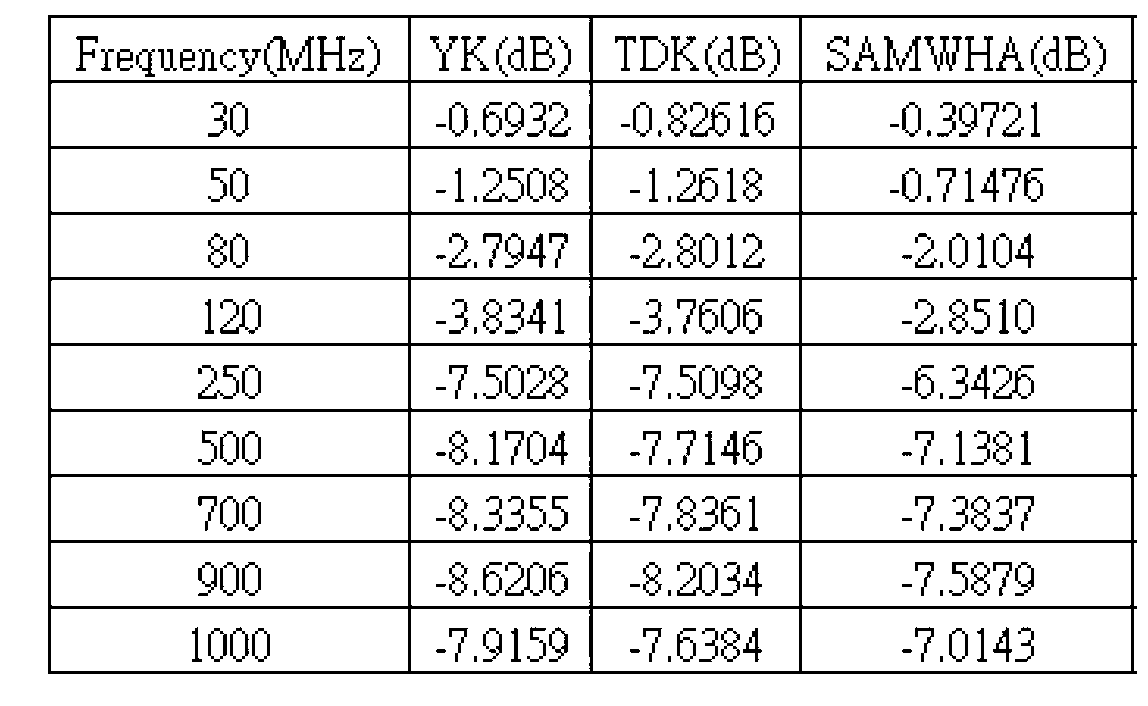

[0059] 2. Use a network analyzer to analyze the reflectivity characteristics of the product in Example 2 at 30 MHz to 1000 MHz. The following table:

[0060]

Embodiment 3

[0062] The composition and production process of the product of Example 3 are the same as those of Example 1, except that the pre-calcination temperature is 850° C., and the grinding and pulverization time is 2 hours.

[0063] 1. Use a laser particle size analyzer (MS2000) to analyze the particle size distribution of the powder. Its 50% particle size distribution of embodiment 3 product is 1.687 (micron), and 90% particle size distribution is 2.984 (micron), and the average grain diameter after firing is 13.9 (micron).

[0064] 2. Use a network analyzer to analyze the reflectivity characteristics of the product in Example 3 at 30 MHz to 1000 MHz. The following table:

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com