Preparation method of triclosan carbon nano-tube molecule imprinted polymer and determination method of content of triclosan applied to daily chemical products

A technique of imprinting polymers and molecular imprinting, applied in chemical instruments and methods, material separation, analysis of materials, etc., can solve problems affecting accuracy, difficulty in enriching trace samples, and complicated processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

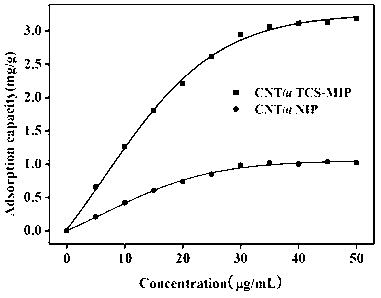

Examples

Embodiment 1

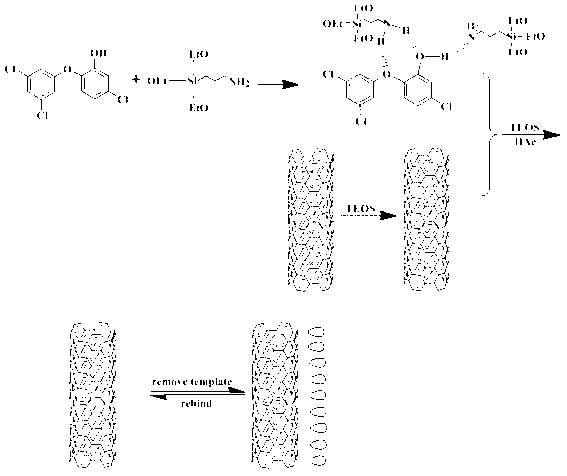

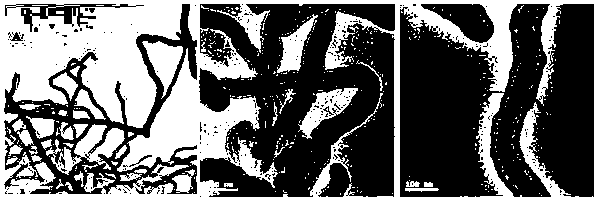

[0071] 1) Silicon-coated carbon nanotubes (CNTSiO 2 ) preparation

[0072] Put 250 mg of purified CNT, 0.5 mL of APTES, 100 mg of CTAB, and 48 mL of deionized water into a 100 mL Erlenmeyer flask, sonicate at 40°C for 20 min, then stir at the maximum speed of a magnetic stirrer for 3 h to obtain a mixture A. Put 5mLTEOS, 3mL deionized water, and 50mL ethanol in a 100mL Erlenmeyer flask, sonicate at 40°C for 20min, and then stir for 3h at the maximum speed of a magnetic stirrer to obtain a mixture B. After the mixture A and B were mixed again, they were sonicated at 40°C for 1 h, then stirred at the maximum speed of a magnetic stirrer for 10 min, and finally, the pH value of the mixture was adjusted to 9.5 with ammonia water. After centrifuging the resulting mixed solution, wash it repeatedly with deionized water and ethanol several times until the supernatant after centrifugation is neutral, and obtain silicon-coated carbon nanotubes CNTSiO 2 . The resulting CNTSiO 2 Vacuu...

Embodiment 2

[0097] Triclosan recovery test in river water using triclosan carbon nanotubes. Add 100 mg of triclosan carbon nanotubes to 100 mL of spiked (0.1, 0.3, 0.5 ug / L) river water for extraction. The mixture was shaken on a shaker for 30 min, centrifuged at 4000 r / min for 5 min, and the supernatant was discarded. Add 40mL methanol / acetic acid (9:1, v:v) to the above centrifuge tube, shake and elute for 12h, centrifuge at 4000r / min for 5min, collect the supernatant, pass through a 0.22μm filter membrane and transfer to another centrifuge tube middle. Blow the eluent to near dryness with nitrogen at room temperature, add 1.0 mL of methanol to dissolve, sample 60 μL, and inject it into high-performance liquid chromatography for determination.

[0098] The measurement results are shown in Table 1.

Embodiment 3

[0100] Triclosan recovery rate test in lake water using triclosan carbon nanotubes. Add 100mg triclosan carbon nanotubes to 100mL lake water spiked with standard (0.1, 0.3, 0.5ug / L) for extraction. The mixture was shaken on a shaker for 30 min, centrifuged at 4000 r / min for 5 min, and the supernatant was discarded. Add 40mL methanol / acetic acid (9:1, v:v) to the above centrifuge tube, shake and elute for 12h, centrifuge at 4000r / min for 5min, collect the supernatant, pass through a 0.22μm filter membrane and transfer to another centrifuge tube middle. Blow the eluent to near dryness with nitrogen at room temperature, add 1.0 mL of methanol to dissolve, sample 60 μL, and inject it into high-performance liquid chromatography for determination.

[0101] The measurement results are shown in Table 2.

[0102] Table 1

[0103]

[0104] (RSD is relative standard deviation)

[0105] Table 2

[0106]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com