Method of preparing liquid anaerobic polyferrocarbosilane

A polycarbosilane and oxygen-free technology, which is applied in the field of compound preparation, can solve the problems of insoluble and infusible, uneven dispersion of iron elements, etc., and achieve the effects of high yield, easy engineering and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Under the protection of an inert atmosphere, vinyl ferrocene is added to liquid hyperbranched polycarbosilane, and the mass ratio of vinyl ferrocene to liquid hyperbranched polycarbosilane is 1%;

[0019] (2) Under the protection of an inert atmosphere, the mixture described in step (1) was stirred in an oil bath at 70° C. for 48 hours to obtain a liquid oxygen-free polyferrocarbosilane.

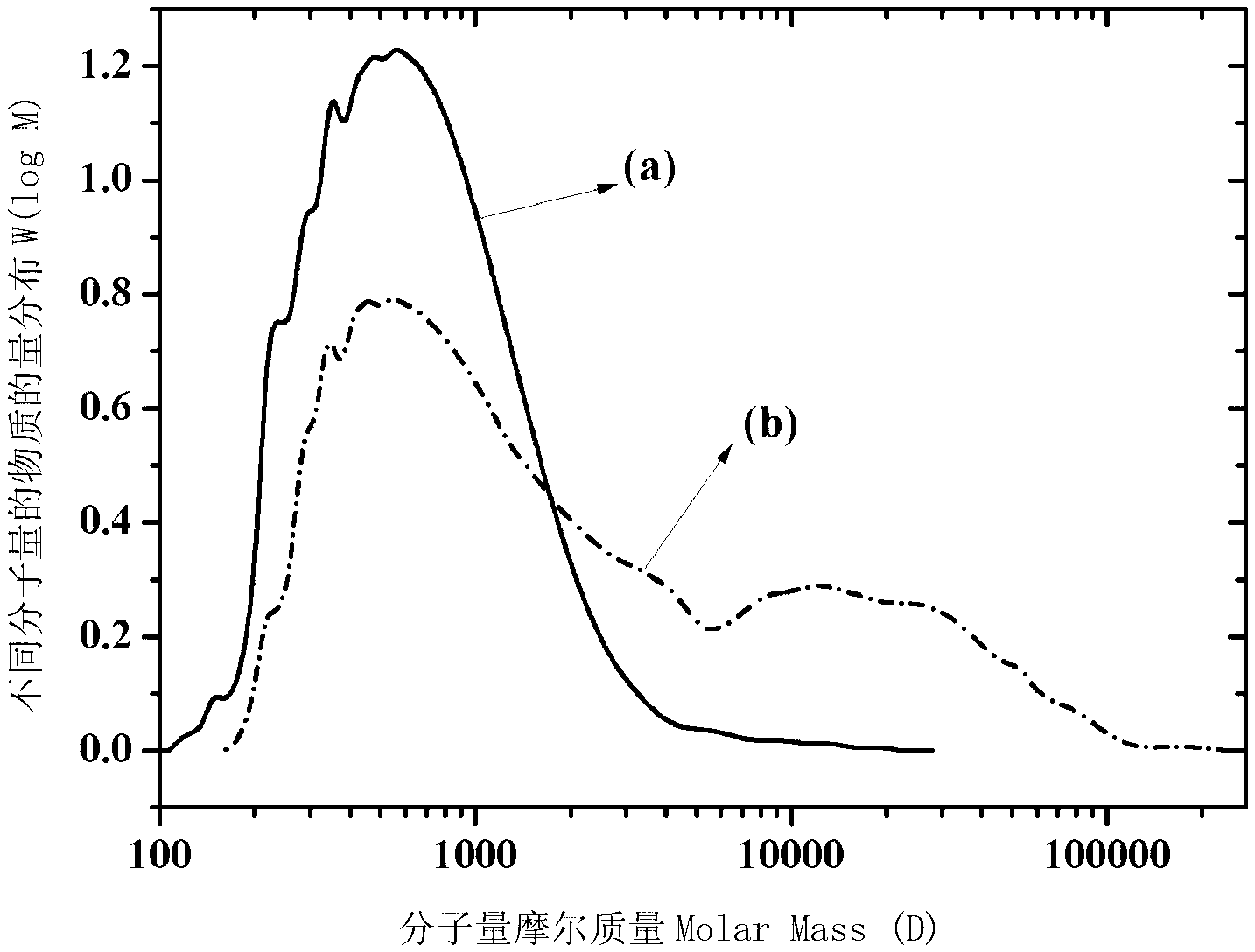

[0020] The average structural formula of the raw material liquid hyperbranched polycarbosilane used is—[SiH 1.6 (CH 3 ) 0.3 —(CH 2 CH=CH 2 ) 0.1 —CH 2 ] n —, measure the molecular weight and molecular weight distribution of liquid hyperbranched polycarbosilane by gel permeation chromatography (GPC), the eluent is tetrahydrofuran, the number average molecular weight is 500, and the dispersion coefficient is 1.7; the liquid anaerobic type obtained after the reaction The number-average molecular weight of polyferrocarbosilane is 900, and the dispersion coefficient is 8.7 (see ...

Embodiment 2

[0022] (1) Under the protection of an inert atmosphere, vinyl ferrocene is added to the liquid hyperbranched polycarbosilane, and the mass ratio of vinyl ferrocene to liquid hyperbranched polycarbosilane is 10%;

[0023] (2) Under the protection of an inert atmosphere, the mixture described in step (1) was stirred in an oil bath at 30° C. for 48 hours to obtain a liquid oxygen-free polyferrocarbosilane.

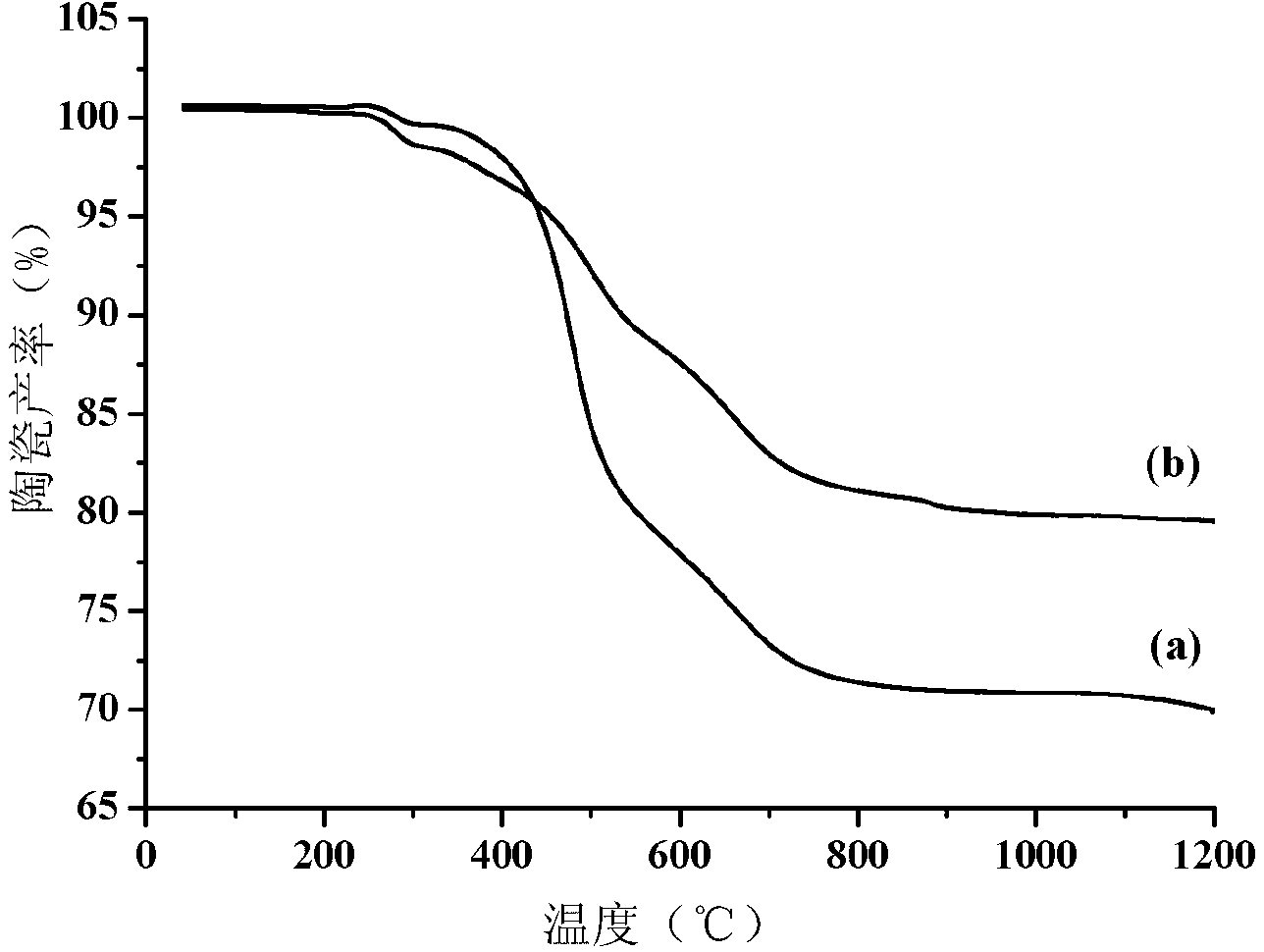

[0024] The average structural formula of the raw material liquid hyperbranched polycarbosilane used is—[SiH 1.5 (CH 3 ) 0.5 —CH 2 ] n -, the number average molecular weight is 600, and the dispersion coefficient is 3.5; the number average molecular weight of the liquid oxygen-free polyironcarbosilane obtained after the reaction is 1000, and the dispersion coefficient is 4.5; the synthesis yield is 95.2wt%. The ceramic yield of liquid oxygen-free polycarbosilane 1200°C pyrolysis product was determined by thermogravimetric analysis (TGA) to be 83.2wt%, while the ceramic yie...

Embodiment 3

[0026] (1) Under the protection of an inert atmosphere, vinyl ferrocene is added to liquid hyperbranched polycarbosilane, and the mass ratio of vinyl ferrocene to liquid hyperbranched polycarbosilane is 20%;

[0027] (2) Under the protection of an inert atmosphere, the mixture described in step (1) was stirred in an ice-water bath at 0° C. for 36 hours to obtain a liquid oxygen-free polyferrocarbosilane.

[0028] The average structural formula of the raw material liquid hyperbranched polycarbosilane used is—[SiH 1.5 (CH 3 ) 0.3 (C≡CH) 0.2 —CH2 ] n -, the number average molecular weight is 600, and the dispersion coefficient is 3.5; the number average molecular weight of the liquid oxygen-free polyironcarbosilane obtained after the reaction is 1500, and the dispersion coefficient is 6.2; the synthesis yield is 85.3wt%. The ceramic yield of liquid oxygen-free polycarbosilane cracked at 1200°C was determined by thermogravimetric analysis (TGA) to be 84.2wt%, while the ceramic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com