Formula based on modified hydrophobic SiO2 (silicon dioxide) self-cleaning paint and preparation method thereof

A self-cleaning and modified technology, applied in the direction of coating, etc., can solve the problem of unsatisfactory silica effect, and achieve the effect of promoting and improving the hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

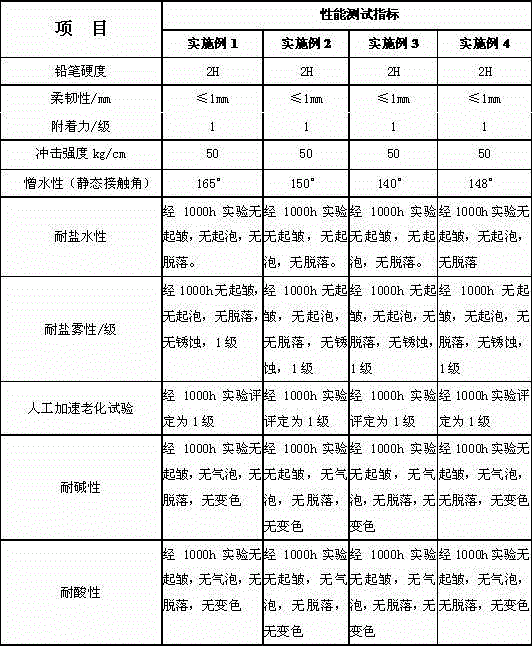

Examples

preparation example Construction

[0031] The preparation method of the present invention comprises the following processing steps:

[0032] A), according to the above components and their mass percentages, dissolve the fluorosilicone resin in an aromatic hydrocarbon ester mixed solvent, and stir at a speed of 200 rpm to 1000 rpm for 5 to 30 minutes;

[0033] B), coating modified SiO with hydroxyl-terminated polydimethylsiloxane 2 Add to the solution prepared in step A, and stir at a speed of 2500-3000 rpm for 20-60 minutes until the dispersion is uniform;

[0034] C), during construction, add curing agent to the mixed solution prepared in step B, the relative mass ratio range of curing agent to the mixed solution prepared in step B is 0.4:100~0.72:100, after stirring evenly, pass Apply to the surface of the substrate by brushing, spraying, etc., and cure at room temperature to form a cross-linked film.

[0035] The aromatic hydrocarbon ester mixed solvent is a mixed solvent in which xylene and butyl acetate ...

Embodiment 1

[0038] Composed of the following components and their mass percentages: 25% fluorosilicone resin, hydroxyl-terminated polydimethylsiloxane coated modified nano-SiO 2 30%, xylene, butyl acetate mixed solvent 45% in a ratio of 1:1, also including polyisocyanate.

[0039] Add polyisocyanate during construction, and the relative mass ratio range of polyisocyanate to the above components is 0.4:100.

[0040] First, gas-phase SiO 2 The powder is dispersed in the xylene solution, the concentration of the powder relative to the solution is 0.01g / m3, first stirred at 2500 rpm for 60 minutes, then ultrasonically dispersed for 10 minutes, until the dispersion is uniform, and then 80000mPas of hydroxyl-terminated polymer is added Dimethylsiloxane, which reacts with gas-phase SiO 2 The mass ratio is 1:10. After mixing and stirring evenly, dibutyltin dilaurate is added as a catalyst. 20.1% of the total mass, mixed and stirred, heated to 80°C, and the reaction time was controlled at 0.5 h...

Embodiment 2

[0044] It consists of the following components and their mass percentages: 45% fluorosilicone resin, hydroxyl-terminated polydimethylsiloxane coated modified nano-SiO 2 25%, xylene, butyl acetate mixed solvent 30% in a ratio of 1:1, also including polyisocyanate.

[0045] Add polyisocyanate during construction, and the relative mass ratio range of polyisocyanate to the above components is 0.72:100.

[0046] First, gas-phase SiO 2 The powder is dispersed in the xylene solution, the concentration of the powder relative to the solution is 0.1g / m3, first stirred at 2800 rpm for 45 minutes, then ultrasonically dispersed for 20 minutes, until the dispersion is uniform, and then 5000mPas hydroxyl-terminated poly Methylsiloxane, which reacts with gas-phase SiO 2 The mass ratio is 1:1. After mixing and stirring evenly, dibutyltin dilaurate is added as a catalyst. 2 1% of the total mass. Mix and stir, heat up to 70°C, and control the reaction time at 5 hours. The obtained product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com