Formula based on modified hydrophobic SiO2 (silicon dioxide) self-cleaning paint and preparation method thereof

A self-cleaning and modified technology, applied in the direction of coating, etc., can solve the problem of unsatisfactory silica effect, and achieve the effect of promoting and improving the hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

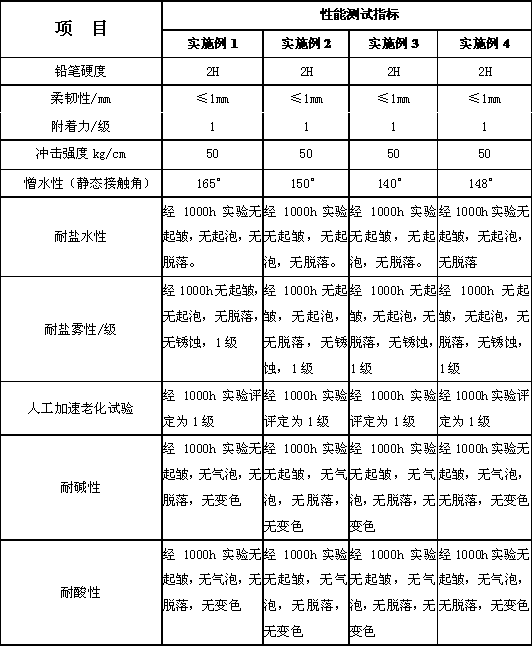

Examples

preparation example Construction

[0031] The preparation method of the present invention comprises the following processing steps:

[0032] A), according to the above components and their mass percentages, dissolve the fluorosilicone resin in an aromatic hydrocarbon ester mixed solvent, and stir at a speed of 200 rpm to 1000 rpm for 5 to 30 minutes;

[0033] B), coating modified SiO with hydroxyl-terminated polydimethylsiloxane 2 Add to the solution prepared in step A, and stir at a speed of 2500-3000 rpm for 20-60 minutes until the dispersion is uniform;

[0034] C), during construction, add curing agent to the mixed solution prepared in step B, the relative mass ratio range of curing agent to the mixed solution prepared in step B is 0.4:100~0.72:100, after stirring evenly, pass Apply to the surface of the substrate by brushing, spraying, etc., and cure at room temperature to form a cross-linked film.

[0035] The aromatic hydrocarbon ester mixed solvent is a mixed solvent in which xylene and butyl acetate ...

Embodiment 1

[0038] Composed of the following components and their mass percentages: 25% fluorosilicone resin, hydroxyl-terminated polydimethylsiloxane coated modified nano-SiO 2 30%, xylene, butyl acetate mixed solvent 45% in a ratio of 1:1, also including polyisocyanate.

[0039] Add polyisocyanate during construction, and the relative mass ratio range of polyisocyanate to the above components is 0.4:100.

[0040] First, gas-phase SiO 2 The powder is dispersed in the xylene solution, the concentration of the powder relative to the solution is 0.01g / m3, first stirred at 2500 rpm for 60 minutes, then ultrasonically dispersed for 10 minutes until the dispersion is uniform, and then 80000mPa·s of hydroxyl sealant is added Terminated polydimethylsiloxane, which with gas-phase SiO 2 The mass ratio is 1:10. After mixing and stirring evenly, dibutyltin dilaurate is added as a catalyst. 20.1% of the total mass, mixed and stirred, heated to 80°C, and the reaction time was controlled at 0.5 hour...

Embodiment 2

[0044] It consists of the following components and their mass percentages: 45% fluorosilicone resin, hydroxyl-terminated polydimethylsiloxane coated modified nano-SiO 2 25%, xylene, butyl acetate mixed solvent 30% in a ratio of 1:1, also including polyisocyanate.

[0045] Add polyisocyanate during construction, and the relative mass ratio range of polyisocyanate to the above components is 0.72:100.

[0046] First, gas-phase SiO 2 The powder is dispersed in the xylene solution, the concentration of the powder relative to the solution is 0.1g / m, first stirred at 2800 rpm for 45 minutes, then ultrasonically dispersed for 20 minutes, until the dispersion is uniform, and then 5000mPa·s hydroxyl end capping is added Polydimethylsiloxane, which with gas-phase SiO 2 The mass ratio is 1:1. After mixing and stirring evenly, dibutyltin dilaurate is added as a catalyst. 2 1% of the total mass. Mix and stir, heat up to 70°C, and control the reaction time at 5 hours. The obtained produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com