Molded sapphire crystal growth method and apparatus thereof

A technology of sapphire crystal and growth method, which is applied in the field of crystal growth, can solve the problems of high requirements for operators, high difficulty in seeding the growth method, and low material utilization rate, and achieve simplified post-processing procedures, stable product quality, and reduced processing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

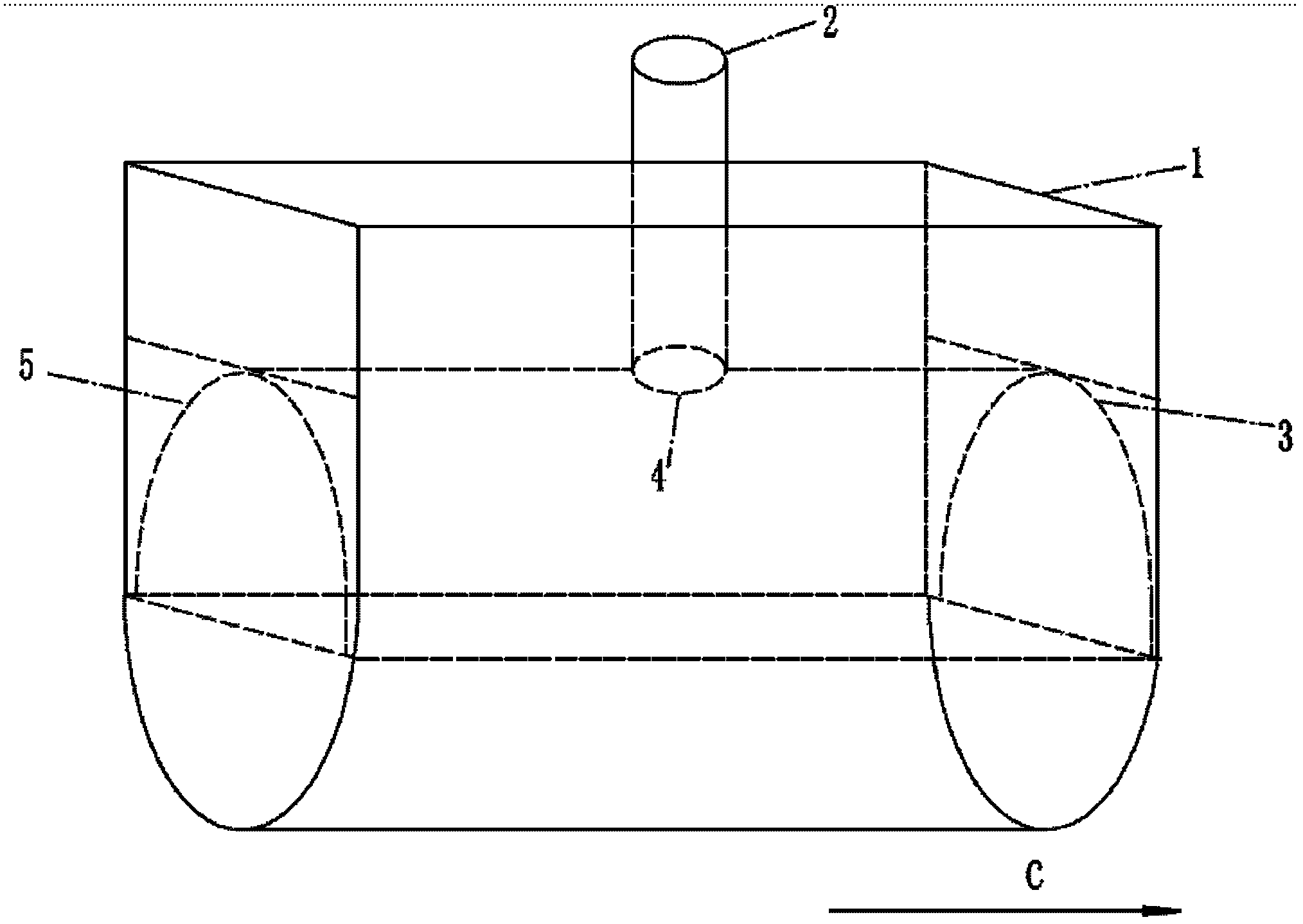

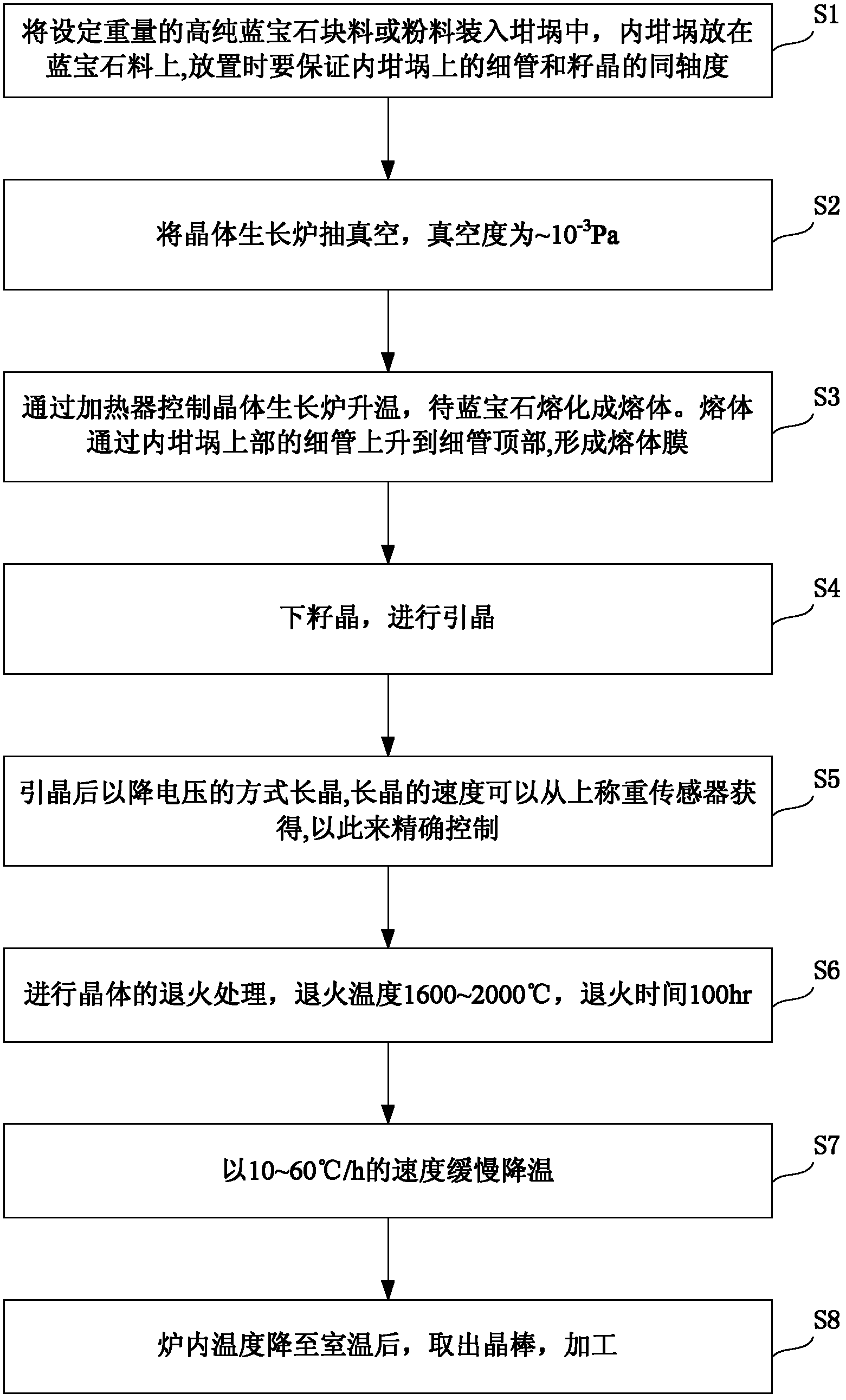

[0048] see figure 1 , the present invention discloses a growth device for forming sapphire crystals, said device comprising: a crystal growth furnace (not shown in the figure), a heater (not shown in the figure), a crucible 1, an inner crucible 3, a weighing system (not shown in the figure ).

[0049] The inner crucible 3 is arranged in the crucible 1, and a hole 4 is arranged on the top of the inner crucible 3, and a thin tube 2 is connected through the hole 4, and the diameter of the thin tube 2 is 6-12mm, which plays the role of a capillary. It is used to obtain a small interface higher than the free liquid surface 5 to facilitate seeding; the inner crucible 3 is placed on the sapphire material to ensure the coaxiality of the thin tube 2 on the inner crucible 3 and the seed crystal.

[0050] The thin tube 2 is the position of the cooling core, and as the temperature drops, the crystal begins to grow; the weighing system accurately controls the rate of crystal growth, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com