Method for preparing graphene paper through utilizing electric field guidance

A graphene paper and graphene technology, applied in the direction of graphene, chemical instruments and methods, papermaking, etc., can solve the problems of low mechanical strength, achieve good mechanical properties, high conductivity, easy and feasible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

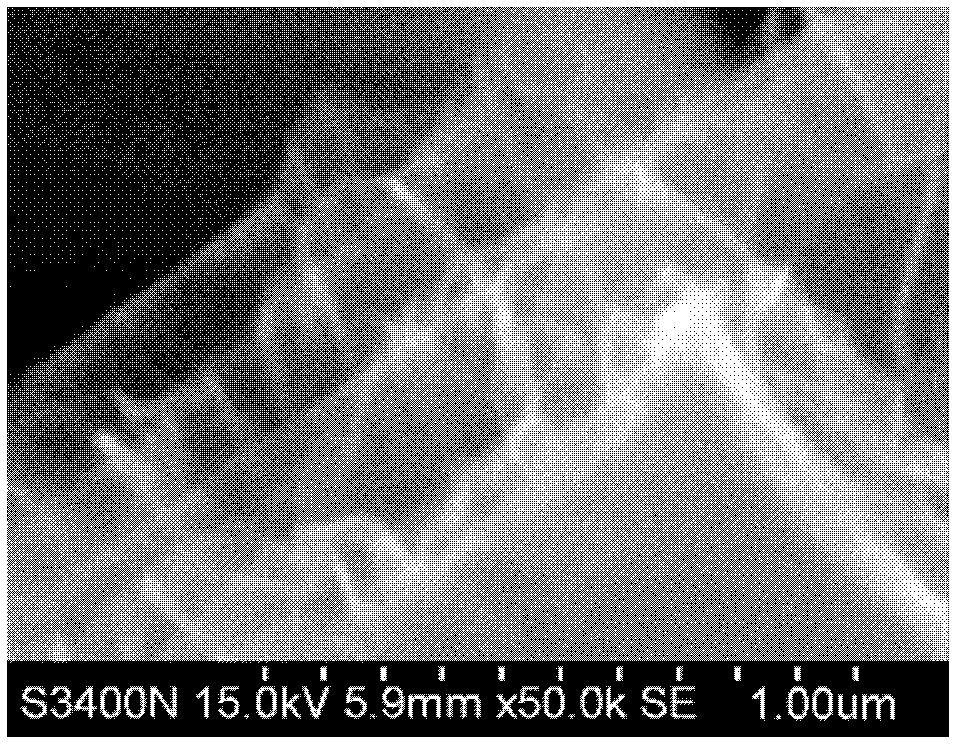

Image

Examples

Embodiment 1

[0028] Utilize the method for electric field guidance to prepare graphene paper, comprise the following steps:

[0029] (1) Get 10g ferric chloride intercalation graphite and join in the beaker, then add 1L deionized water, under stirring, be made into the intercalation graphite suspension that concentration is 10g / L;

[0030] (2) Ultrasonic treatment is carried out to the intercalated graphite suspension, and ultrasonic cleaner is used for 10 minutes, and the power of the ultrasonic cleaner is preferably 150w, so that the intercalated graphite is peeled off, and a solution containing graphene is obtained;

[0031] (3) Pour the solution containing graphene into the filter funnel, and place the filter funnel in a uniform electric field with an electric field strength of 200V / m. Under the guidance of the electric field force and the interaction force of the charge, the solution containing graphene Graphene is deposited;

[0032] (4) After the graphene is basically deposited, fi...

Embodiment 2

[0036] Utilize the method for electric field guidance to prepare graphene paper, comprise the following steps:

[0037] (1) Get 5g cobalt chloride intercalation graphite and join in the beaker, then add 1L deionized water, under stirring, be made into the intercalation graphite suspension that concentration is 5g / L;

[0038] (2) Ultrasonic treatment is carried out to the intercalated graphite suspension, and ultrasonic cleaner is used for 15 minutes, and the power of the ultrasonic cleaner is preferably 400w, so that the intercalated graphite is peeled off, and a solution containing graphene is obtained;

[0039] (3) Pour the solution containing graphene into the filter funnel, and place the filter funnel in a uniform electric field with an electric field strength of 50V / m. Under the guidance of the electric field force and the interaction force of the charge, the solution containing graphene Graphene is deposited;

[0040] (4) After the graphene is basically deposited, filte...

Embodiment 3

[0043] Utilize the method for electric field guidance to prepare graphene paper, comprise the following steps:

[0044] (1) Get 6g potassium chloride intercalation graphite and join in the beaker, then add 1L deionized water, under stirring, be made into the intercalation graphite suspension that concentration is 6g / L;

[0045] (2) Ultrasonic treatment is carried out to the intercalation graphite suspension, and the ultrasonic cleaner is used for 12 minutes, and the power of the ultrasonic cleaner is preferably 200w, so that the intercalation graphite is peeled off, and a solution containing graphene is obtained;

[0046] (3) Pour the solution containing graphene into the filter funnel, and place the filter funnel in a uniform electric field with an electric field strength of 100V / m. Under the guidance of the electric field force and the interaction force of the charge, the solution containing graphene Graphene is deposited;

[0047] (4) After the graphene is basically deposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com