Flame-suppression and explosion-suppression cryogenic liquefaction device for low-concentration coal bed gas

A liquefaction device and coalbed methane technology, applied in the direction of refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of increasing deoxidation equipment, sacrificing methane recovery rate, increasing equipment investment and operating costs, and achieving explosion prevention, purity and recovery rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

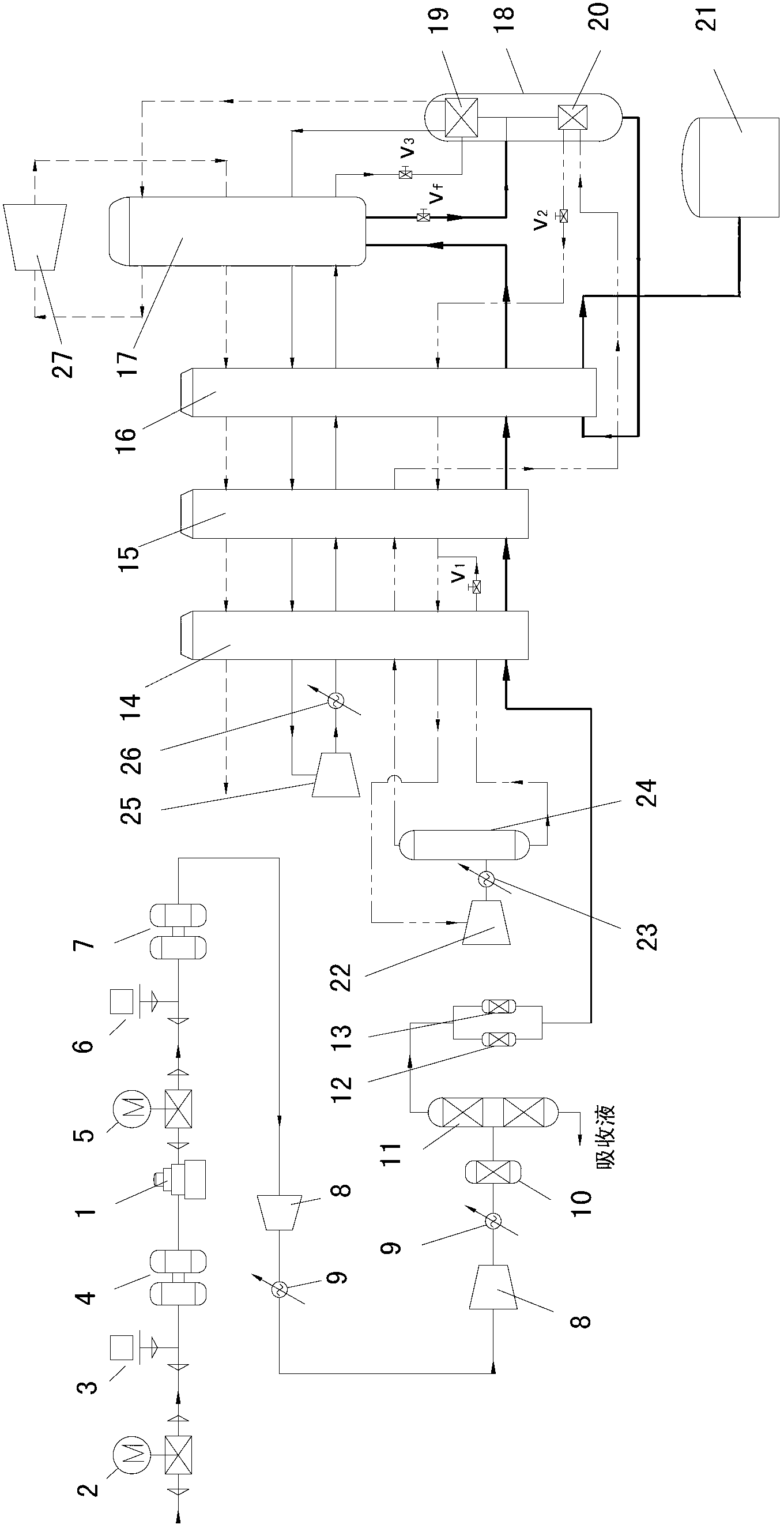

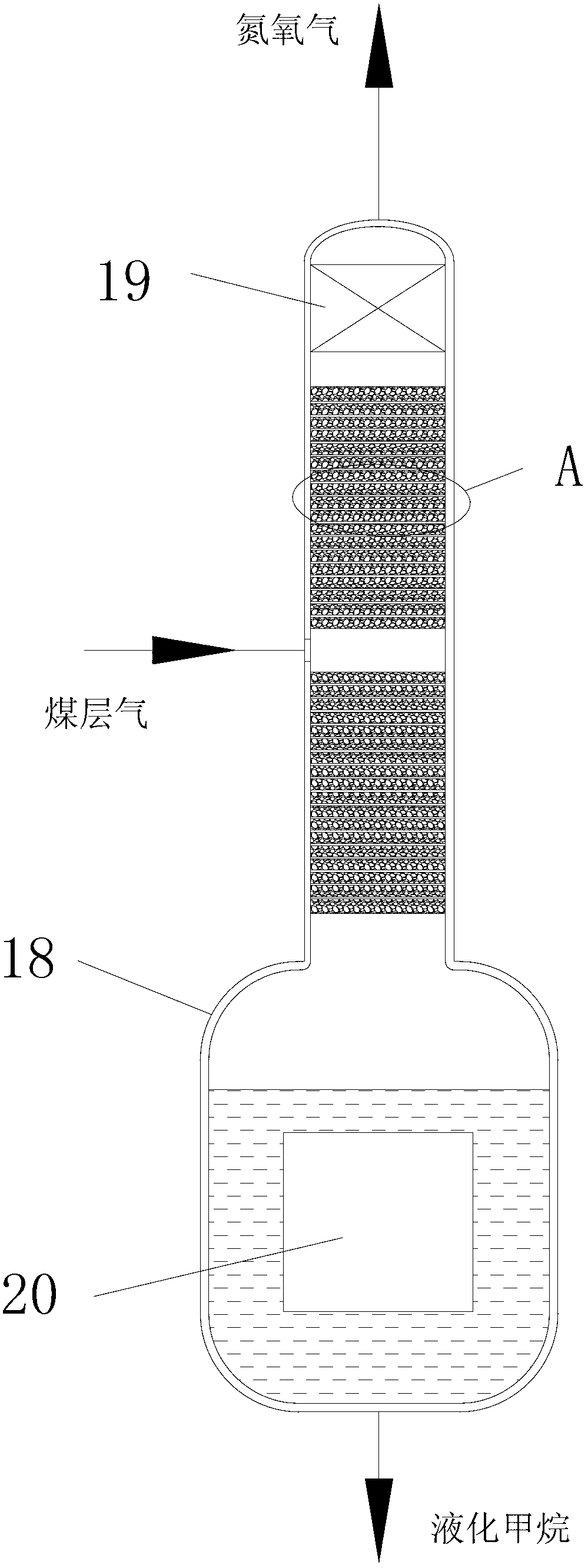

[0037] Such as figure 1 As shown, it is a structural schematic diagram of an embodiment of the low-concentration coalbed methane cryogenic liquefaction device of the present invention. The low-concentration coalbed methane cryogenic liquefaction device for suppressing combustion and explosion in this embodiment includes a coalbed methane storage system, a coalbed methane compression system, a coalbed methane purification system, a coalbed methane liquefaction and separation system, an LNG storage system, and a system for supplying to the The coalbed methane liquefaction and separation system provides a cooling refrigeration cycle system, and the front and rear sides of the coalbed methane storage system are equipped with active explosion suppression devices.

[0038]The coalbed methane storage system includes a gas cabinet 1, and the activ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com