Coiling fixture, with air channel supporting bar positioning function, of iron-core-type electric reactor

A technology of winding fixtures and support bars, which is applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor cooling, circuit, etc., which can solve the problem of poor control of product quality, inability to provide positioning function, low winding efficiency, etc. problems, to achieve the effect of convenient and reliable implementation, improved convenience, and guaranteed winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

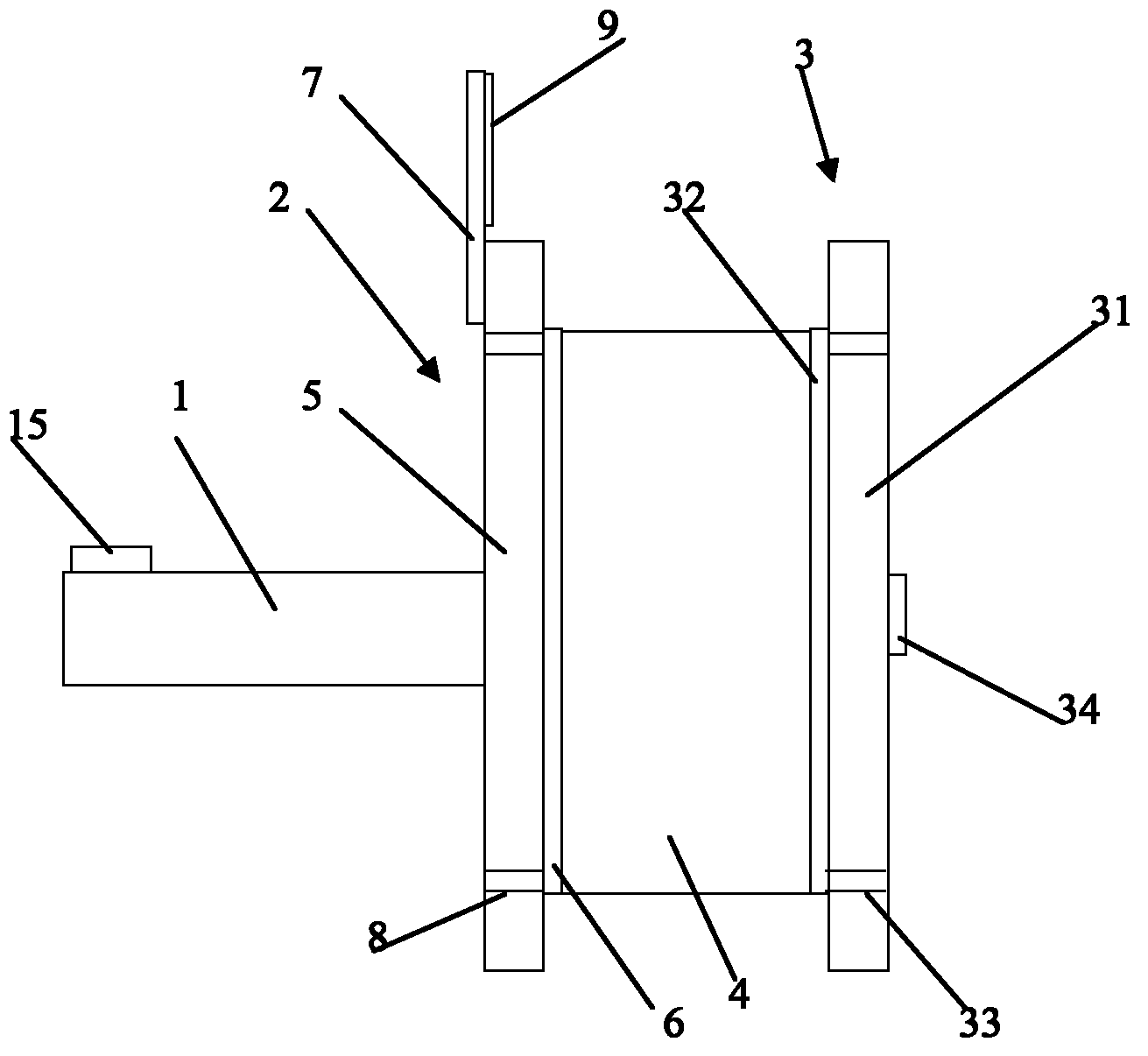

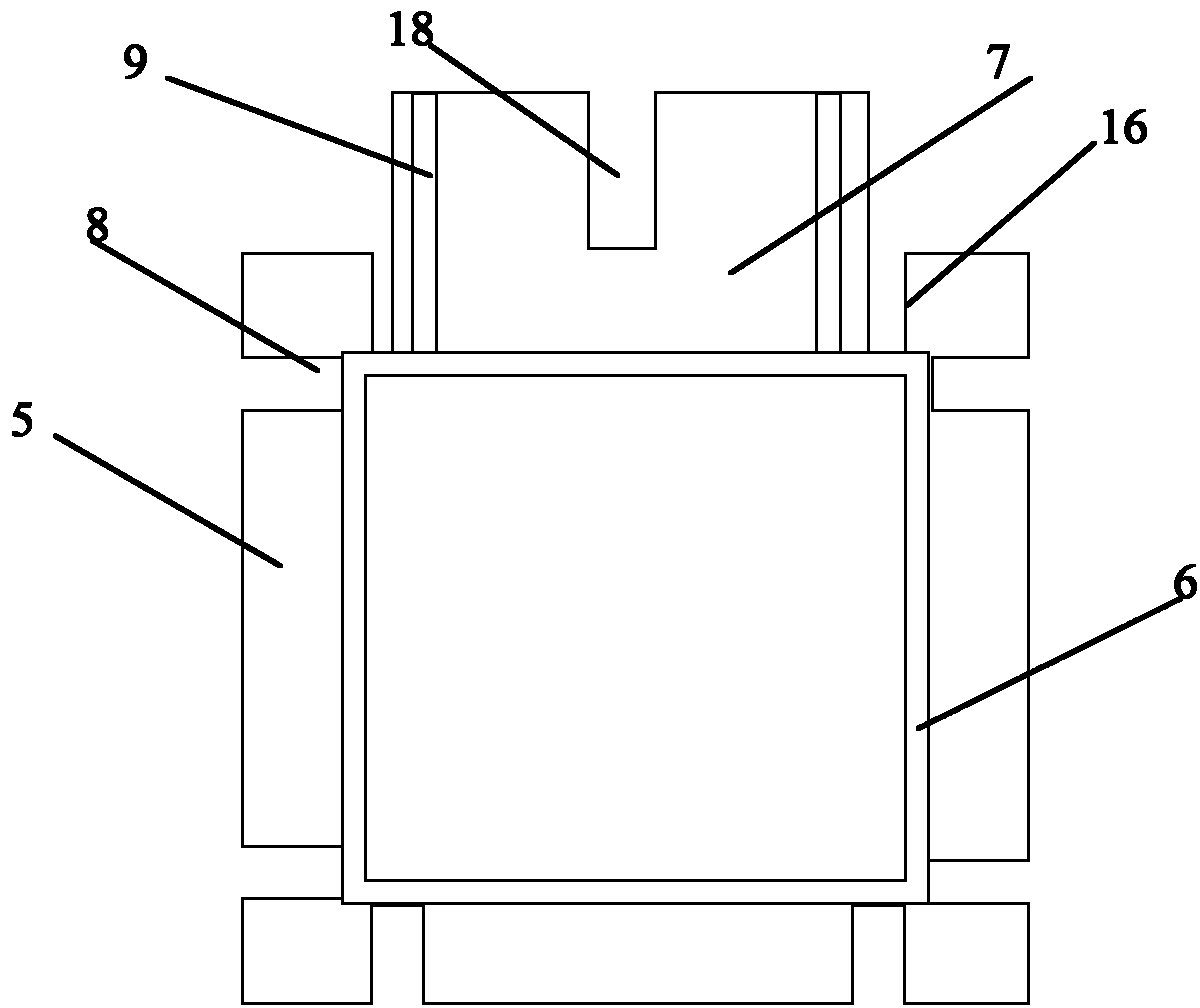

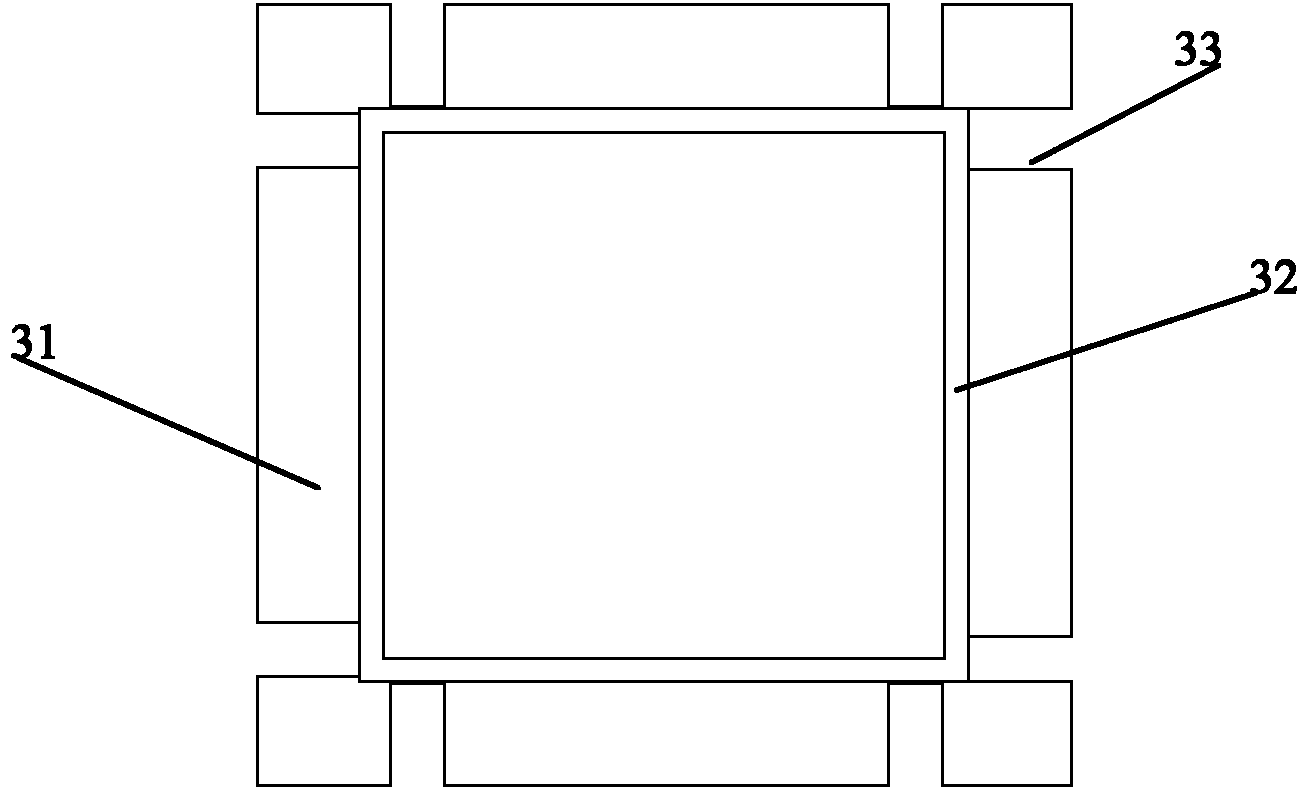

[0019] Such as figure 1 and 2 Shown is the winding fixture of the iron core reactor with airway support bar positioning function of the present invention, wherein the iron core reactor includes an iron core, copper foil or copper tape wound on the iron core and a fixed setting Copper row at the end of copper foil or copper strip, the winding device of the reactor includes a rotating drive plate, a pressing roller and a tail positioning shaft, the rotating drive plate is driven by a motor to drive the main shaft, and the rotating drive plate is Expansion-type modular structure, which can be opened or locked to clamp or release the transmission rod. The pressure roller is driven by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com