Hydrogen storage alloy, electrode, nickel-metal hydride storage battery and manufacturing method of hydrogen storage alloy

一种贮氢合金、制造方法的技术,应用在贮氢合金领域,能够解决不能充分提高贮氢合金耐腐蚀性等问题,达到提高耐腐蚀性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0071] The chemical composition is in accordance with the situation described in the following Table 1. Weigh the raw material ingot with a specified amount, add Ni and Y to the crucible after adding La and Al, and use a high-frequency melting furnace under a reduced-pressure argon atmosphere to heat and melt to 1500 ℃, and then put in MgNi 2 , Ca melting. After melting, the melt spinning method is used for rapid cooling, and the alloy is solidified at 1000°C / sec. Then, the obtained alloy was heat-treated at 970° C. for 5 hours in an argon atmosphere, and then pulverized to obtain a hydrogen storage alloy powder having an average particle diameter (D50) of 50 μm.

Embodiment 6~10、 comparative example 4~6

[0094] The chemical composition is in accordance with the situation described in the following Table 2. Each raw material ingot is weighed with a specified amount, and after adding La, Ce, Pr, Nd, Al, Mn, Ni, Co, Y are added to the crucible, and the Under the use of high-frequency melting furnace heating to 1500 ℃, melting material. After melting, cooling was performed using a water-cooled mold at 50° C. / second to solidify the alloy. Then, the obtained alloys were heat-treated at 1000° C. for 5 hours in an argon atmosphere, and then pulverized to obtain hydrogen storage alloy powders with an average particle diameter (D50) of 50 μm. It should be noted,

[0095] The average particle diameter was measured using an MT3000 device manufactured by Microtrak.

reference example 1、2

[0099] The chemical composition is as described in the following Table 2. Weigh each raw material ingot with a specified amount, add Ni and Y to the crucible after adding La and Al, and heat and melt it to 1500 °C in a high-frequency melting furnace under a reduced-pressure argon atmosphere. ℃, and then put in MgNi 2 , Ca melting. After melting, the melt spinning method is used for rapid cooling, and the alloy is solidified at 1000°C / sec. Next, the obtained alloys were heat-treated at 970° C. for 5 hours in an argon atmosphere, and then pulverized to obtain hydrogen storage alloy powders with an average particle diameter (D50) of 50 μm.

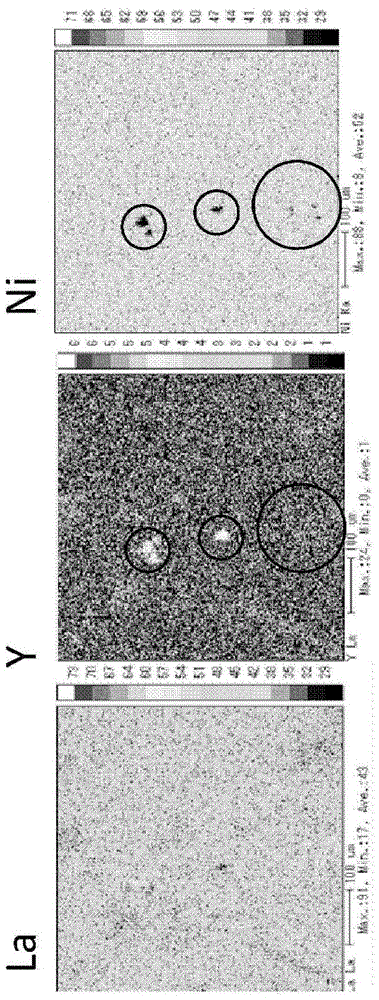

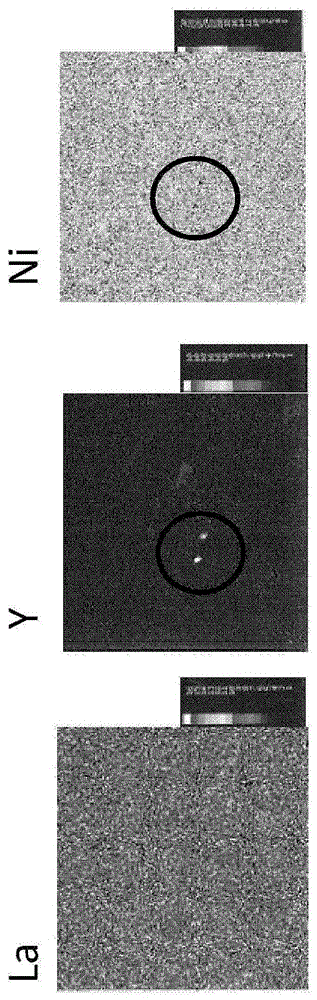

[0100] (2) Determination of concentration distribution of Y

[0101] After the hydrogen storage alloy ingot is resin-fixed, it is ground and cleaned with sandpaper. It should be noted that instead of ingots, powders or nickel metal hydride storage battery electrode groups may be used. Grind in such a way that the cross-section of the ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com