Preparation method and application of cobalt-loaded mesoporous graphite-phase carbon nitride visible-light-induced catalyst

A graphite-phase carbon nitride and cobalt-loaded mesoporous technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of high cost and limited application of loaded precious metals, and achieve catalytic activity Enhanced, good reference value, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

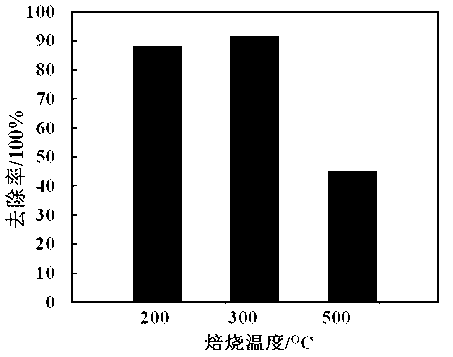

[0041] (1) Mix silica sol HS-40 and cyanamide at a mass ratio of 1:0.32 (silica sol 15.625g), dry in vacuum at 40°C, and then bake at 550°C for 4 hours in a muffle furnace, then heat up At a rate of 2°C / min, the obtained product was washed with 4mol / L ammonium bifluoride solution to remove silica sol, washed with water by centrifugation, and dried to obtain mpg-C 3 N 4 ;

[0042] (2) Immerse 0.222g of cobalt nitrate hexahydrate solution in 1.455g of mpg-C 3 N 4 In the process, stir continuously at 80°C until the solution is evaporated to dryness, and then bake the second time in a muffle furnace at 300°C for 2 hours with a heating rate of 2°C / min to obtain 3%Co / mpg-C 3 N 4 .

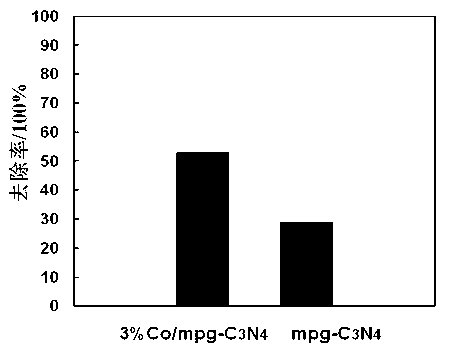

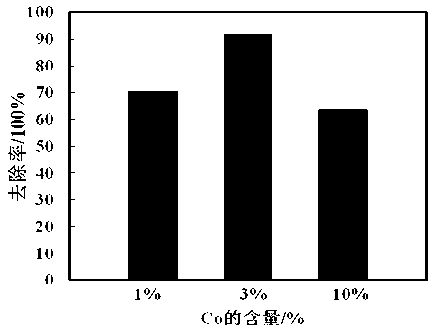

[0043] (3) 3%Co / mpg-C will be obtained 3 N 4 Mix the catalyst and methylene blue solution in the photocatalytic reactor, the initial concentration of methylene blue is 80mg / L, the amount of catalyst added is 0.4g / L, the solution temperature is controlled at 15°C, after stirring for 30min, 500W xenon...

Embodiment 2

[0048] (1) Mix silica sol HS-40 and cyanamide at a mass ratio of 1:0.8 (silica sol 6.25g), dry it in vacuum at 70°C, then bake at 600°C for 6 hours in a muffle furnace, then heat up At a rate of 2°C / min, the obtained product was washed with 4mol / L ammonium bifluoride solution to remove silica sol, washed with water by centrifugation, and dried to obtain mpg-C 3 N 4 ;

[0049] (2) Immerse 0.222g of cobalt nitrate hexahydrate solution in 1.455g of mpg-C 3 N 4 In the process, stir continuously at 50°C until the solution is evaporated to dryness, and then bake the second time in a muffle furnace at 300°C for 2h, with a heating rate of 2°C / min, to obtain 3%Co / mpg-C 3 N 4 .

[0050] (3) Mix the obtained methylene blue solution in a photocatalytic reactor, the initial concentration of methylene blue is 25mg / L, and the catalyst is 3%Co / mpg-C 3 N 4 The amount of the solution added was 0.4g / L, and the solution temperature was controlled at 15°C. After stirring for 30 minutes, it ...

Embodiment 3

[0052] In Example 1, other conditions remain unchanged, and the mass ratio of silica sol HS-40 to cyanamide in step (1) of Example 1 is changed to 1:0.4 (silica sol 12.5g), so as to obtain 3%Co / mpg- C 3 N 4 It is catalyst, and its visible light catalytic reaction condition is identical with embodiment 2. After 180 min of photocatalytic reaction, the removal rate of methylene blue was 80.28%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com