Buried glass fiber reinforced plastic double-wall oil storage tank monitored through liquid medium and preparing method of buried glass fiber reinforced plastic double-wall oil storage tank

A glass fiber reinforced plastic and oil storage tank technology, applied in the direction of containers, packaging, underwater structures, etc., can solve the problems of low tensile modulus and mechanical strength, complex preparation process, and increased material consumption, and achieve the tensile modulus. And the effect of high mechanical strength, high safety performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

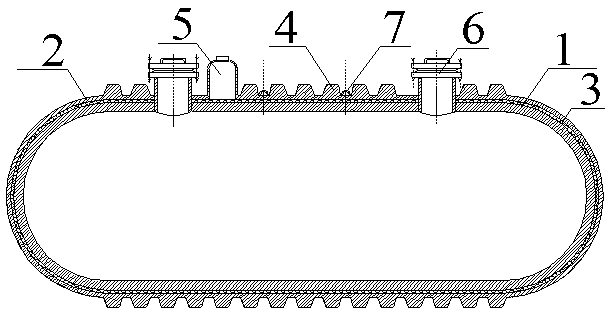

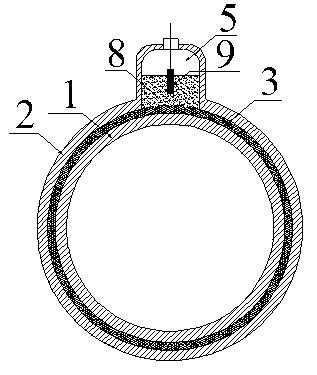

[0040] Such as figure 1 As shown, a buried FRP double-wall oil storage tank adopting liquid medium monitoring, it includes: inner tank body (1), outer tank body (2) and hollow layer (3), described hollow layer (3 ) is formed by bonding the outer wall of the inner tank body (1) and the inner wall of the outer tank body (2) by a three-dimensional hollow fabric, and the outer wall of the outer tank body (2) is provided with a solid reinforcing rib (4), which is connected with the hollow layer (3 ) connected to the water storage tank (5), the manhole (6) and the lifting lug (7);

[0041] The inner tank body (1) is composed of an inner lining layer, an inner anti-seepage layer, a structural layer and an outer anti-seepage layer from the inside to the outside;

[0042] The outer tank body (2) is composed of an inner anti-seepage layer, a structural layer and an outer anti-seepage layer from the inside to the outside.

[0043]The above-mentioned buried FRP double-walled oil storage...

Embodiment 2

[0051] A method for preparing a glass fiber reinforced plastic double-wall oil storage tank monitored by a liquid medium, comprising the following steps:

[0052] a. Production of half-inner tank

[0053] First, lay polyester film on the half-inner tank winding mold with head, start the power device to make the winding mold rotate around the mandrel;

[0054] Then on the winding mold, the glass fiber surface mat is impregnated with thermosetting resin, and the inner liner is prepared by spraying or winding process; after the inner liner is cured, the surface of the inner liner is sprayed by spraying process, and the glass fiber jet yarn and thermosetting resin are sprayed at the same time , and then rolled to prepare the inner anti-seepage layer; after the inner anti-seepage layer is cured, the glass fiber reinforced yarn or fabric impregnated with thermosetting resin is laid on the surface of the inner anti-seepage layer by winding process to prepare the structural layer; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com